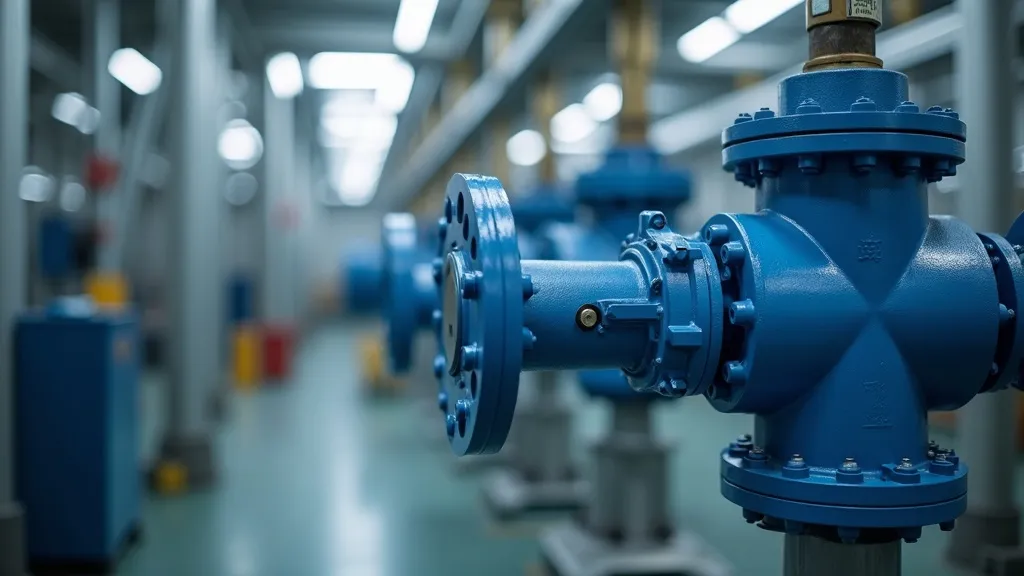

The Rexroth Valve is a crucial component in industrial and hydraulic systems, known for its reliability and performance. Serving a broad range of applications, these valves are designed by Bosch Rexroth AG, a leading company in engineering high-quality solutions for motion control. This article delves into the various facets of Rexroth Valves, exploring their applications, advantages, and frequently asked questions.

The Rexroth Valve plays a pivotal role in industries requiring precise motion and fluid control. Manufactured by Bosch Rexroth AG, these valves epitomize innovation and reliability, catering to numerous applications from manufacturing to energy management. As industries evolve, the demand for robust and adaptable components like the Rexroth Valve continues to soar, underscoring their significance in modern engineering. This article aims to delve deeper into the various aspects of Rexroth Valves, exploring their features, applications, mechanics, maintenance, and much more to provide a comprehensive overview of this essential component in fluid power systems.

Rexroth Valves are crafted to meet the rigorous demands of industrial applications. Key features include:

Rexroth Valves find extensive use across several domains, each demanding specific functionalities:

| Model | Flow Capacity | Operating Pressure | Application |

|---|---|---|---|

| 4WE6J | Up to 40 L/min | 350 bar | Mobile Hydraulics |

| DB10 | Up to 160 L/min | 315 bar | Industrial Hydraulics |

| SL20PA | Up to 1000 L/min | 210 bar | Electrohydraulic Systems |

| PVG 32 | Up to 160 L/min | 350 bar | Mobile Applications |

| VgM 400 | Up to 400 L/min | 420 bar | Industrial Applications |

| REXROTH A4V | Up to 280 L/min | 400 bar | Construction Machinery |

Rexroth Valves utilize advanced engineering to regulate the flow of fluids in hydraulic and pneumatic systems. These valves operate using electromagnetic solenoids or manual levers, which actuate the valve mechanism, controlling the fluid's direction, pressure, and volume within the system. The precise design allows for reduced fluid friction, enhancing the efficiency of the entire system.

The design of these valves takes into account several mechanical principles. For instance, many Rexroth Valves include a spool assembly that is moved within a cylindrical bore. The position of the spool determines the flow path through the valve, directing fluid to various outlets or back to the reservoir, depending on the command given by the actuator. Additionally, pilot-operated features can provide greater control, allowing for smoother transitions between positions and minimizing shock loads on hydraulic systems.

Another essential aspect is the pressure compensation mechanism integrated into some models. This feature helps maintain a constant pressure output, even when the load conditions vary, which is vital for applications requiring steady force and speed control. In sectors such as automotive assembly or material handling, this consistency translates to improved safety and efficiency in operations.

Furthermore, modern advancements have led to the introduction of smart valves equipped with digital communication capabilities. These valves can interface with control systems for data collection and analysis, enabling operators to optimize their processes and integrate predictive maintenance strategies. The introduction of IoT technology further elevates the functionality of Rexroth Valves, allowing for real-time monitoring and adjustments based on operational conditions.

Proper maintenance of Rexroth Valves is crucial for ensuring longevity and optimal performance. Regular inspections, cleaning, and timely replacement of worn components are recommended to maintain optimal performance. Here are some best practices for maintaining Rexroth Valves:

In the event of failure, common symptoms such as erratic motion, unusual noise, or changes in pressure should be carefully examined. Troubleshooting might involve checking for obstructions, verifying electrical connections, and reviewing actuator responses. It’s advisable to consult the specific model’s technical manual for precise diagnostic procedures.

With rapid advancements in technology, Rexroth Valves continue to evolve, incorporating state-of-the-art features that keep pace with modern demands. Some innovative technologies now featured in Rexroth Valves include:

Rexroth Valves are designed to meet a wide range of global standards and compliance requirements that ensure safety, reliability, and environmental sustainability. Here are several notable standards that are typically adhered to:

Compliance with these standards not only enhances product credibility but also reassures clients regarding the safety and reliability of Rexroth Valves in their applications, bolstering customer trust and satisfaction.

In the realm of industrial machinery and fluid control systems, the Rexroth Valve stands as a beacon of engineering excellence. Its innovative design, coupled with robust performance and energy efficiency, makes it an indispensable tool across various sectors. Whether in manufacturing, agriculture, or energy, Rexroth Valves provide the reliability and precision necessary to meet the needs of modern industries. As technology advances, their role will undoubtedly expand, further cementing their position as leaders in valve technology. Additionally, the continuous development of smart technologies, adherence to global standards, and the proactive approach to maintenance demonstrate Rexroth's commitment to excellence and innovation. The evolving landscape of industrial processes will continue to embrace Rexroth Valves as key components that drive efficiency, safety, and sustainability in a rapidly changing world.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!