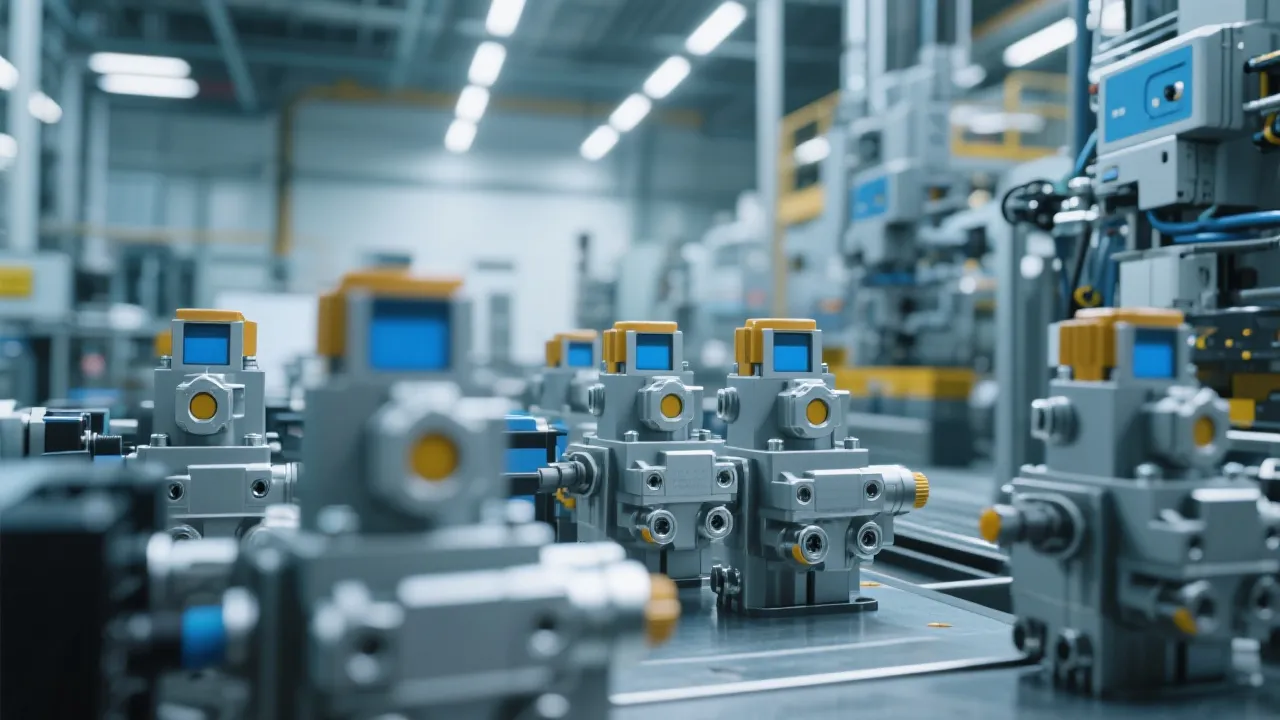

The Rexroth Servo Valve stands as a pinnacle in precision control technology, essential for numerous industrial applications. This intricate device plays a crucial role in managing hydraulic fluids in complex systems, facilitating smooth and efficient operations across various sectors like aerospace and manufacturing.

In today's fast-paced industrial landscape, precision and reliability are paramount. Servo valves, particularly the Rexroth Servo Valve, have emerged as vital components across various sectors, including aerospace, automotive, and manufacturing. These valves are celebrated for their ability to precisely control hydraulic fluid flow, thus playing an integral role in automation and efficiency enhancement. The transition from mechanical systems to electronically controlled systems has made servo valves an essential part of modern industrial machines.

The Rexroth Servo Valve is engineered to offer unparalleled precision. It functions by regulating hydraulic fluid to actuators, coordinating their movements with exceptional accuracy. This capability allows industries to achieve high precision in operations that require meticulous control. The valve typically comprises a sophisticated assembly of electrical coils, a spool, feedback devices, and a nozzle-flapper mechanism, each contributing to its precise operation.

The actuator’s movements are influenced by variations in electrical signals applied to the valve, which affect the position of the spool within the valve housing. The nozzle-flapper design increases sensitivity, allowing even minor changes in the control signal to result in significant changes in the valve’s output, enhancing responsiveness and accuracy. The feedback devices, often encoded with position sensors, continuously measure the position and movement of system components, enabling closed-loop control systems that ensure fidelity to the predetermined trajectory or operational parameters.

One of the critical applications of the Rexroth Servo Valve is in the aerospace industry, where it is used to control the movement of aircraft components. Such precision ensures flight safety and optimal performance. For example, these valves are used in flight control systems, where slight inaccuracies can lead to serious safety concerns. Similarly, in automotive manufacturing, these valves contribute to the automation of production lines, enhancing speed and productivity. Robot arms in assembly processes rely on servo valves to operate smoothly, ensuring tight tolerances and rapid cycle times are met in manufacturing.

In addition to aerospace and automotive applications, Rexroth Servo Valves are also utilized in industrial robotics, plastic injection molding, and CNC machining. These valves enhance machine performance, providing precise speed and position control, which is essential in applications requiring high degrees of automated precision.

The benefits of adopting Rexroth Servo Valves are manifold:

Rexroth Servo Valves are available in several specifications, catering to different pressure and flow rate requirements. Typical specifications include flow rates from 5 L/min to 360 L/min, with pressure ratings often above 350 bar (approximately 5,000 psi), suitable for a range of industrial applications. The price of these valves varies significantly, depending on the technical specifications and customization options selected. For instance, options like integrated electronics, advanced feedback systems, or specialized fluid compatibility can affect the overall cost.

Potential buyers should consider their unique operational needs and consult with suppliers to determine the most suitable model. A thorough consultation process may include a needs analysis, where factors such as operational environment, load characteristics, and control requirements are evaluated to identify the best-fit valve. It’s also wise to inquire about the availability of replacement parts and potential upgrades as technology evolves.

When selecting a supplier for Rexroth Servo Valves, it is crucial to consider factors such as the supplier's reputation, the availability of technical support, and the warranty offered. Working with established and authorized Rexroth distributors can ensure access to genuine products and professional assistance. This is particularly important because counterfeit or subpar components can lead to failures that compromise both safety and performance.

In addition to reputation, consumers should assess the level of technical acumen offered by their suppliers. Technical support can be invaluable, especially in complex setups where integration of servo valves into existing systems must be performed. A knowledgeable supplier will also be able to provide training resources, installation support, and post-sale service to address any operational issues that may arise.

Implementing Rexroth Servo Valves into your operation can significantly enhance overall performance, but several considerations must be addressed to ensure successful integration. Firstly, it is essential to evaluate the existing hydraulic systems currently in place. Older systems may require upgrades to function optimally with new servo valves, as compatibility issues can lead to performance bottlenecks or operational failures.

Next, personnel training is crucial. Staff should be well-versed in both theoretical aspects and practical operation of servo-controlled systems. Training creates a foundation of understanding that enhances an operator's ability to identify problems and implement effective troubleshooting solutions. This in-depth knowledge is vital in preventing and promptly addressing potential issues that could affect performance.

Lastly, regular maintenance schedules should be established. Preventive maintenance is critical in prolonging valve life and ensuring optimal performance. Operators should be trained on how to check for wear and tear, assess fluid levels, and confirm that feedback systems are functioning accurately. Establishing a health monitoring system can proactively identify issues before they become critical failures.

What makes Rexroth Servo Valves superior to others?

The Rexroth Servo Valve is renowned for its high precision, reliability, and adaptability across various industrial applications, making it a preferred choice in sectors requiring meticulous fluid control. Its combination of robust design and advanced features enables it to outperform many competitors in demanding environments.

Where can Rexroth Servo Valves be applied?

These valves are extensively used in aerospace, automotive, and manufacturing industries due to their ability to manage complex hydraulic systems effectively. They are also found in sectors such as robotics, renewable energy, and machine tools, where precision and reliability are critical for success.

How do I select the right Rexroth Servo Valve for my application?

Consider factors such as the required flow rate, pressure specifications, and motion control needs. Engaging with a qualified supplier or distributor can also provide guided recommendations tailored to your specific application. Additionally, reviewing technology trends and advancements in servo valve capabilities may help identify the best solutions for prepared integrative applications.

What is the expected lifespan of a Rexroth Servo Valve?

The lifespan of a Rexroth Servo Valve varies greatly depending on operational conditions, maintenance practices, and the specific model in use. Typically, with proper care and maintenance, a high-quality servo valve can function effectively for many years, often exceeding ten years in optimal conditions.

Can Rexroth Servo Valves be replaced with other brands without any loss of performance?

While it is possible to replace Rexroth Servo Valves with alternatives from other manufacturers, it is crucial to ensure that the replacement meets or exceeds the performance characteristics required for your application. System designers must consider compatibility, control capabilities, and overall system integrity. It might be beneficial to conduct thorough testing to confirm that performance will not be compromised during such changes.

Rexroth Servo Valves continue to revolutionize fluid control within intricate systems, marking a significant cornerstone in industrial automation and efficiency. As industries evolve, the demand for such precise and reliable components remains robust, affirming their indispensable role in modern engineering and manufacturing advancements. The convergence of technology and hydraulic systems through these valves not only represents a leap in performance but also lays the groundwork for future innovations in automation and process control.

As the industrial sector continues to embrace automation and digitalization, the role of servo valves like the Rexroth Servo Valve will only become increasingly important. Future advancements are expected to focus on integrating IoT capabilities into servo valves, allowing for real-time data transmission and machine learning analytics. This evolution will enable predictive maintenance, where potential failures can be detected and addressed before they affect production lines.

Moreover, the increasing emphasis on energy efficiency in manufacturing processes will push for the development of more efficient servo valves. Innovations in design that reduce power consumption while preserving or enhancing performance will be critical as industries seek to lower operational costs and minimize environmental impact. Material science will also play a role, with the development of lighter, more durable materials that can withstand extreme conditions while maintaining precise operations.

Collaboration between industries and technology providers will be vital in driving research and development efforts focused on these advancements. Educational institutions may also contribute by preparing the next generation of engineers and technicians equipped to handle the evolving landscape of automated systems that rely heavily on precision valves.

In conclusion, Rexroth Servo Valves and their ilk represent a crucial intersection of precision engineering and automation technology. The continuing evolution of these components suggests not only enhancements in current applications but also the potential emergence of completely new operational paradigms. For businesses willing to invest in the latest servo technology, the rewards will be substantial, leading to improved efficiencies, lower costs, and greater competitive advantages in a global marketplace.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!