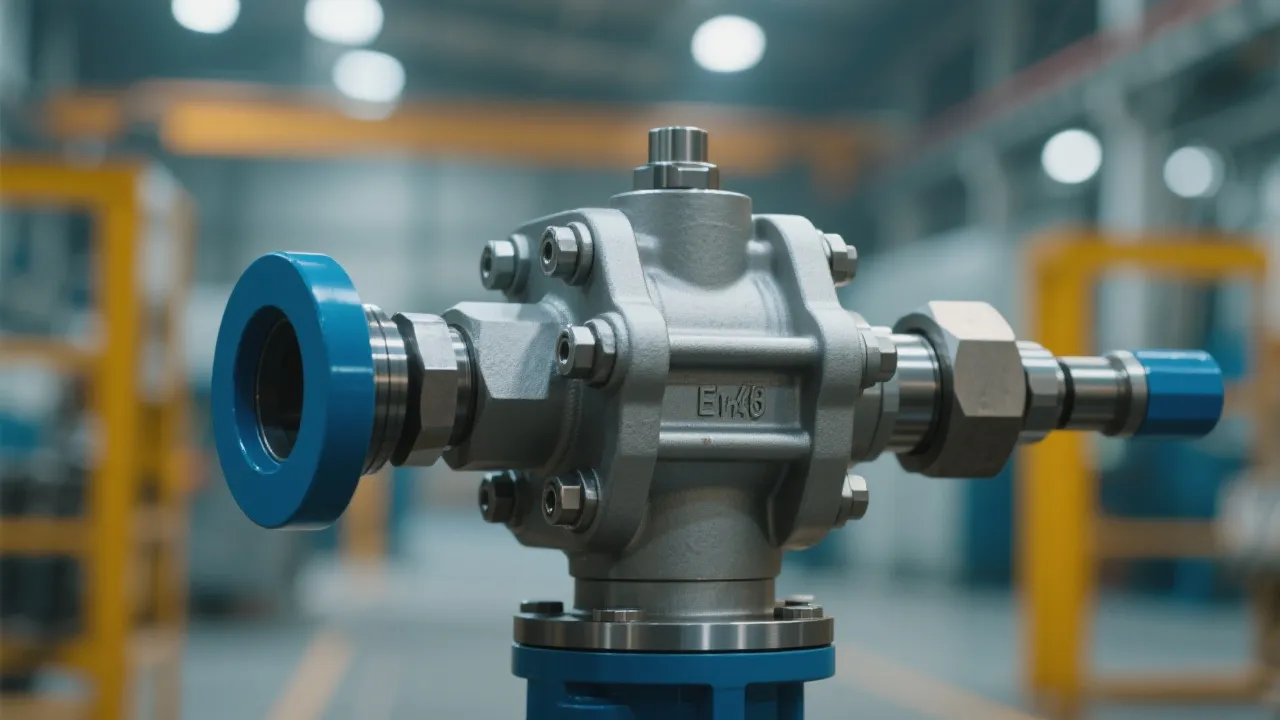

Rexroth valves are essential hydraulic components used in various industrial applications, known for their precision, durability, and efficiency. Developed by Bosch Rexroth, these valves play a critical role in controlling fluid flow and pressure in machinery and equipment across multiple sectors, ensuring optimal performance and reliability.

Rexroth valves, manufactured by Bosch Rexroth, are engineered hydraulic components designed for critical roles in fluid and pressure management within diverse industrial systems. Recognized for their exceptional durability, precision, and efficiency, these valves hold a prominent position across numerous sectors including manufacturing, automotive, and energy. Such widespread application stems from their ability to enhance operational efficiency and safeguard equipment against potential hydraulic system failures. Furthermore, Rexroth has established a reputation for continuous innovation, regularly updating and improving their valve technology to meet the ever-evolving needs of modern industries. The blend of advanced engineering and reliable performance makes Rexroth valves a top choice for manufacturers looking to optimize their operations.

Central to Rexroth valves is their robust construction which promises longevity and minimal maintenance needs. The innovation integrated into these valves is evident in their advanced design that allows seamless adjustments to fluid dynamics, making them a favored choice for engineers aiming for precision and reliability in their systems. The materials used in the manufacturing of Rexroth valves are carefully selected to endure harsh environmental conditions, ensuring performance stability and extended service life. Moreover, these valves often feature integrated technologies such as electronic controls that enhance their adaptability in automated systems, further optimizing operational efficiency.

Rexroth valves bolster industrial performance through their exceptional flow control capabilities. They are adept at managing both the direction and volume of fluid flow, which is vital in machinery operations that demand high precision. Their implementation reduces energy consumption by optimizing system pressure levels, thereby promoting sustainable industrial practices. For instance, in applications demanding variable speed control, Rexroth valves can facilitate fine-tuning of flow to match operational needs, reducing wasted energy and improving process efficiencies. This not only minimizes overhead costs but also aligns industrial operations with modern sustainability initiatives, contributing to a reduced carbon footprint.

The versatility of Rexroth valves is exhibited in their various types, each engineered for specific applications:

Choosing Bosch Rexroth valves is synonymous with selecting technical excellence. The brand leverages state-of-the-art technology and rigorous testing in its manufacturing processes, ensuring each valve meets stringent quality benchmarks. Bosch Rexroth also offers extensive support services, aiding industries in seamless product integration and maintenance. Their global presence means that customers can access local support and have confidence in the availability of replacement parts and service assistance. Moreover, Bosch Rexroth invests heavily in research and development, continuously innovating to advance valve technology and keep pace with market demands.

Industries relying on Rexroth valves benefit from their adaptability and reliability. In the automotive sector, they contribute to the performance and safety of manufacturing equipment, ensuring precision in assembly lines and reducing the likelihood of errors caused by equipment malfunctions. In the energy sector, they play a role in enhancing the operational efficiency of power generation systems, from controlling turbines and pumps to managing the cooling systems essential for safe and efficient operation.

In manufacturing environments, Rexroth valves facilitate automation by allowing for precise control over robotic systems, enhancing production speeds, and ensuring consistent quality in manufactured products. In construction, these valves are critical in heavy machinery, enabling operators to maintain control over hydraulic functions under challenging conditions. Across all these sectors, the reliability of Rexroth valves translates not only into improved performance but also enhanced safety for workers and equipment alike.

Industry experts often commend Rexroth valves for their contribution to modern hydraulic systems. According to authoritative sources, the integration of these valves into systems can lead to a significant reduction in operational downtime and maintenance costs, affirming their cost-effectiveness despite a potentially higher upfront investment. This is especially relevant as industries grapple with increasing pressure to optimize operations and reduce costs amidst competitive market environments. Professionals advocate for the adoption of Rexroth solutions as investments in performance and reliability that yield high returns through improved uptime and system longevity.

Beyond their core functionalities, Rexroth valves are equipped with a range of advanced features designed to enhance performance and efficiency. For instance, the incorporation of electronic control systems allows for real-time adjustments based on operational demands. Using sensors and feedback loops, these systems can adapt flow rates and pressure levels instantaneously, ensuring that machinery responds efficiently to changing conditions. Furthermore, the implementation of diagnostic capabilities facilitates predictive maintenance, allowing operators to identify potential issues before they escalate into serious problems.

Additionally, Rexroth valves often feature modular designs that enable easy customization and retrofitting. This flexibility allows companies to adapt their hydraulic systems as operational requirements evolve without the need for complete overhauls. By supporting various configurations and integrations, these valves can be tailored to suit a wide range of applications, providing solutions that scale with business growth.

Q: What makes Rexroth valves superior to other hydraulic valves?

A: Rexroth valves are distinguished by their precision, robust design, and energy efficiency. They are crafted to meet strict industry standards, delivering unparalleled reliability and performance across various applications. Their advanced technology and extensive testing ensure that they can withstand the rigors of industrial use, making them a preferred choice among engineers and operators alike.

Q: How do I ensure proper installation of Rexroth valves?

A: Proper installation involves consulting Bosch Rexroth's comprehensive guides and possibly collaborating with certified technicians to ensure optimal setup and operation. It is crucial to follow installation protocols carefully to avoid compromising valve performance. Regular training for maintenance personnel can also ensure that they are familiar with installation best practices and troubleshooting common issues.

Q: Are Rexroth valves environmentally sustainable?

A: Yes, their design maximizes efficiency, potentially reducing energy consumption and minimizing the environmental impact of industrial operations. With a growing emphasis on sustainable practices, Rexroth valves contribute to greener manufacturing by promoting energy conservation and optimizing resource use.

In summary, Rexroth valves stand out in the hydraulic components market due to their advanced engineering, reliability, and versatility. Essential for numerous applications across various industries, these valves not only enhance operational efficiency but also contribute to sustainability initiatives within organizations. As industries continue to evolve and face new challenges, the importance of integrating high-quality components like Rexroth valves remains paramount for maintaining competitive advantage and operational integrity.

Furthermore, as the technology surrounding hydraulic systems progresses, Bosch Rexroth is likely to remain at the forefront of innovation, ensuring that their valves evolve to meet future demands. From directional control to pressure and flow management, Rexroth will continue to play a critical role in shaping the future of industrial hydraulics, delivering solutions that empower industries to thrive in an increasingly automated and efficient landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!