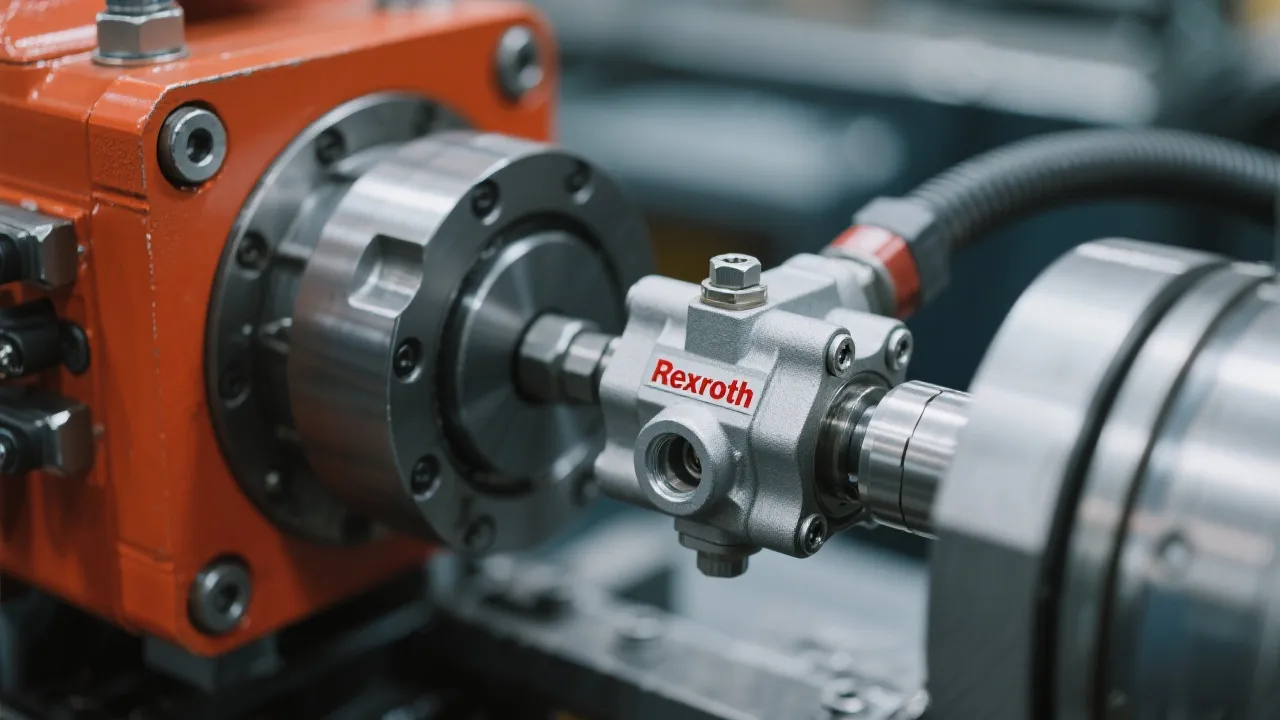

The Rexroth Valve is a critical component in hydraulic systems, known for its exceptional reliability and efficiency. Widely used across various industries, it aids in controlling fluid flow within complex machinery. Its precision engineering contributes significantly to system safety and performance, making it a favored choice for manufacturers globally.

Rexroth valves are revered for their robust construction and operational accuracy, providing essential benefits in a myriad of industrial applications. These valves, manufactured by Bosch Rexroth, are integral to the efficiency and reliability of hydraulic systems. As the industry backbone, they are instrumental in controlling the direction, pressure, and flow of hydraulic fluid. Understanding the functioning of these valves is crucial for engineers and technicians as they navigate the complexities of hydraulic systems in industrial environments. The innovation behind Rexroth's technology has paved the way for advancements in automation, making these valves indispensable tools in streamlining operations and enhancing productivity.

Rexroth valves are ubiquitous in industries such as automotive manufacturing, aerospace, and construction. Their precision ensures optimal performance, leading to increased productivity and reduced downtime. More than just components of machinery, these valves represent the pinnacle of hydraulic engineering. Their quality assurances make them invaluable items, as they are the heart of hydraulic machinery, functioning seamlessly under high pressure and demanding conditions. In modern manufacturing, the trend towards automation relies heavily on the capabilities of Rexroth valves, enabling machines to perform complex tasks with minimal human intervention. This has led to the evolution of smart factories where Rexroth valves play a crucial role in efficient production lines.

The functionality of Rexroth valves greatly depends on several factors, including fluid cleanliness, system maintenance, and adherence to specified operational parameters. Ensuring these conditions are met is vital for optimal performance. The installation environment should be monitored to ensure that temperature, pressure, and fluid characteristics remain within the designated ranges for the types of valves being utilized. For instance, the cleanliness of the hydraulic fluid is crucial, as contaminants can lead to premature wear or failure of valve components. Therefore, filtration devices should be strategically integrated into the hydraulic system to maintain fluid quality.

| Parameter | Requirement |

|---|---|

| Temperature | -30°C to +120°C |

| Pressure | Up to 315 bar |

| Fluid Viscosity | 16 to 380 mm²/s |

| Fluid Cleanliness | ISO 4406 up to 18/16/13 |

| Installation Orientation | Vertical or horizontal based on specifications |

| Cycle Frequency | As per application requirements |

Installation of Rexroth valves should only be carried out by qualified personnel. Proper alignment and mounting are crucial to avoid operational issues. Failure to do so may result in early wear or functional discrepancies. It is recommended to always refer to Bosch Rexroth's installation guidelines for specific models. Regular maintenance, including checking fluid levels and replacing worn components, ensures longevity and performance consistency. Scheduled maintenance checks can help identify potential problems before they escalate, thereby saving costs associated with unscheduled repairs or replacements.

In sectors like manufacturing, these valves facilitate automated processes. In the construction industry, they are central to heavy machinery operation, such as cranes and excavators. Aerospace relies on Rexroth valves to ensure reliability in flight control systems. Specific applications include:

Experts emphasize the importance of selecting the right valve type based on specific industry needs to maximize efficiency. The modular design of Rexroth valves allows for customization, adapting to the unique demands of different industrial applications. This versatility is a key selling point for both manufacturers and end-users alike. By working closely with engineers, companies can select valve specifications that align closely with operational requirements, enhancing performance and minimizing waste.

Additionally, emerging technologies such as the Internet of Things (IoT) are influencing how Rexroth valves are integrated into modern manufacturing systems. Smart sensors and data analytics can be incorporated to monitor valve performance in real-time, facilitating preventative maintenance and improving overall system reliability. Such integration can lead to significant cost savings and reduce downtime in industrial operations.

Overall, the technological innovations brought by Rexroth in the field of hydraulic valves continue to set benchmarks in performance and reliability, making them essential components in contemporary industrial machinery. Their profound impact on automation and operational efficiency cannot be overstated, positioning them as vital assets in any industry where hydraulic systems are employed. As industries continue to evolve towards increasing automation and smart technology integration, the relevance of Rexroth valves will only grow. Businesses that invest in these advanced solutions are likely to see significant improvements in productivity, safety, and overall operational effectiveness.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!