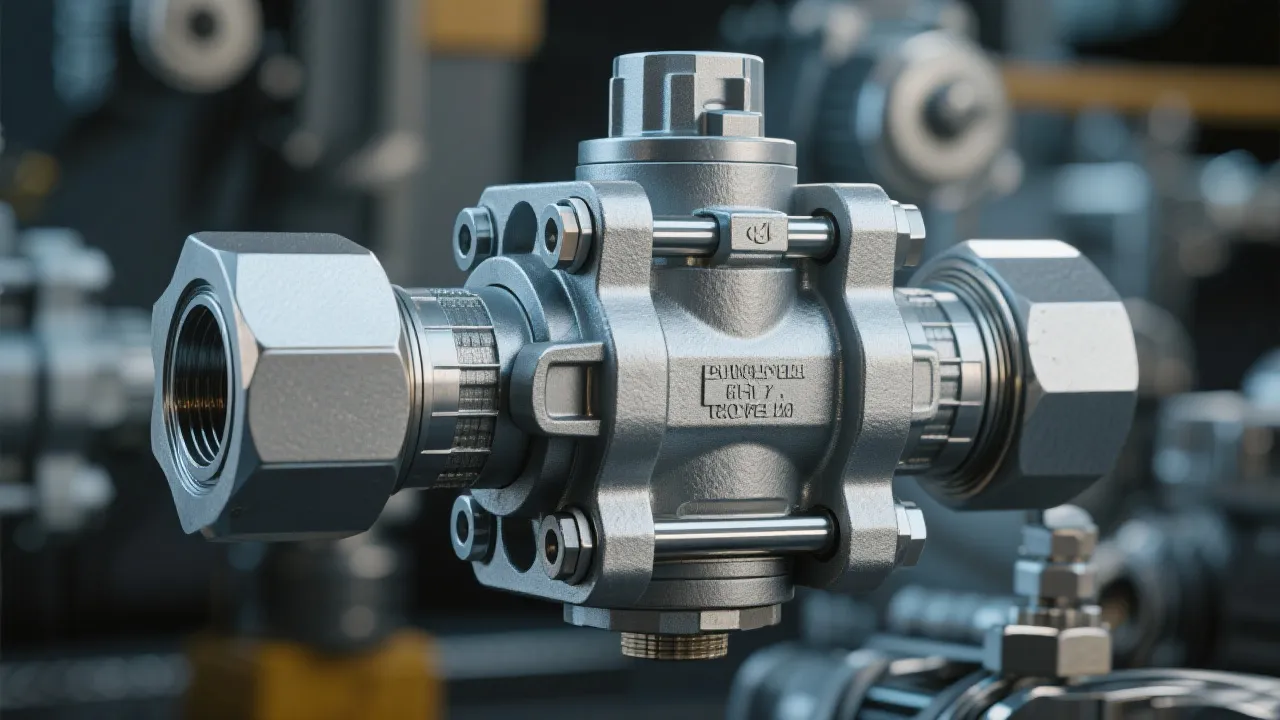

This guide delves into the Rexroth Valve, an integral component in hydraulic systems known for its precision and reliability. Used across diverse industries, these valves enhance efficiency by controlling fluid flow and pressure. As industries such as manufacturing and construction continue to rely on hydraulic systems, the demand for components like Rexroth Valves remains robust.

The Rexroth Valve is renowned for its pivotal role in modern hydraulic systems. Hydraulic valves, like those manufactured by Rexroth, are essential in managing the direct flow and pressure of fluids within complex machinery, thereby ensuring optimal operation. With applications ranging from industrial machinery to construction equipment, Rexroth's products are integral to system efficiency and reliability. The company, part of the Bosch Group, stands out due to its innovation in hydraulic technology and commitment to quality that has earned it a solid reputation in the industry.

In various industrial applications, the precision and durability of Rexroth Valves are prized for maintaining stable operations. The valves are engineered to withstand demanding conditions, providing users with solutions that continue to perform under pressure. Their adaptability and specialized design cater to a wide range of sectors, including aviation, manufacturing, and construction, where hydraulic efficiency is paramount. These valves play a critical role in ensuring machines operate as intended, preventing downtime and maintenance issues that can arise from fluid flow irregularities.

Rexroth Valves have become essential in operations that require the management of heavy machinery. In the construction industry, for example, hydraulic systems control everything from excavators to cranes. Without reliable valves, the risk of equipment failure increases, leading to safety hazards and potential financial losses due to equipment repair and project delays. The reliability of Rexroth Valves translates into peace of mind for operators working in high-stakes environments.

Rexroth Valves are built with advanced technology to support different hydraulic functions, including direction control, pressure control, and flow control. Each valve undergoes rigorous testing for quality assurance, ensuring longevity and robust performance. The design features of these valves include high flow capacity, minimal pressure loss, and exceptional accuracy in fluid regulation. In addition to these core features, there are several technical specifics that set Rexroth Valves apart from the competition.

One of the standout characteristics of Rexroth Valves is their ability to handle high-temperature environments. Many industries, such as metal processing and mining, operate at elevated temperatures that can compromise traditional hydraulic components. Rexroth has engineered its valves to maintain integrity and performance even in extreme conditions. Furthermore, their incorporation of smart technology, including sensors for real-time monitoring, enhances performance by allowing for preventive maintenance and immediate response to potential issues.

Another significant feature is their modular design, which allows users to customize and expand hydraulic systems tailored to specific needs. This flexibility aids in scaling operations and adapting to different projects or technology changes without needing extensive overhauls. The comprehensive range of Rexroth Hydraulics solutions also includes proportional valves, which offer precision control of flow and pressure, providing an even higher level of performance for complex systems.

The hydraulic components market is experiencing steady growth, bolstered by ongoing advancements in industries leveraging automation and mechanization. The demand for efficient and powerful hydraulic technology is driven by the need for enhanced productivity and cost savings. Rexroth, as a leader in this sector, sees significant demand owing to the robustness and efficiency of its valve systems. According to industry reports, the growing emphasis on energy efficiency and resource management further amplifies the demand for such high-performance hydraulic solutions. Companies now prioritize systems that not only perform effectively but also utilize energy resources more sustainably.

The integration of Industry 4.0 into manufacturing processes is another trend impacting the hydraulic components market. Smart technologies are becoming increasingly crucial in optimizing operational efficiency and ensuring predictive maintenance capabilities. Rexroth Valve systems are at the forefront of this technological evolution, featuring integrated communication capabilities that allow for seamless interaction with other smart components within a hydraulic system. This interconnectedness is essential for achieving real-time data analysis and responsive operation, further enhancing the role of Rexroth Valves in modern industrial settings.

Additionally, due to global advocacy for reducing carbon footprints, many industries are exploring electrification of hydraulic components as an alternative to traditional systems. Rexroth is actively investing in developing hybrid systems that combine electric and hydraulic technologies, optimizing performance while minimizing environmental impact. This strategic approach not only positions Rexroth as an innovator but also aligns the company with global sustainability trends, allowing it to capture new markets.

The primary advantages of Rexroth Valves lie in their reliability and efficiency. Operators in industries ranging from automotive manufacturing to heavy machinery rely on Rexroth's designs for consistent performance. Their ability to manage high pressure and variable flow rates makes these valves indispensable to any operation demanding precise hydraulic control. Additionally, their compatibility with various system interfaces ensures a smooth integration into existing setups. This flexibility significantly reduces installation times and costs, addressing another common pain point in hydraulic operations.

Another key advantage is the extensive support and service network provided by Rexroth. Users are not just purchasing a valve; they gain access to a wealth of resources, including technical support, training, and comprehensive documentation. This ensures that operators can maximize the capabilities of their hydraulic systems and troubleshoot any issues that may arise. Furthermore, Rexroth's active engagement in continuing education through workshops and seminars ensures that industry professionals stay informed about the latest advancements and operational best practices.

The durability of Rexroth Valves is another compelling factor. Constructed from high-quality materials, these valves are designed to withstand the rigors of continuous use, reducing the likelihood of costly failures. Companies that choose Rexroth experience longer service intervals and lower total cost of ownership. With proper installation and periodic maintenance, the life expectancy of Rexroth Valves often exceeds that of competing products, reinforcing the value of this investment.

| Feature | Rexroth Valves | Competitors |

|---|---|---|

| Durability | High-quality materials ensure longevity | Varies, often less consistent |

| Precision | Highly accurate control | Often less responsive |

| Flow Capacity | Superior flow management | Average comparative flow rates |

| Pressure Handling | Efficient pressure control | May experience more frequent issues |

| Energy Efficiency | Advanced energy-saving features | Generally standard offerings |

| Support Services | Extensive global network | Limited to regional availability |

Rexroth Valves remain at the forefront of hydraulic technology thanks to their superior engineering and adaptability to diverse industrial needs. As reliance on effective hydraulic solutions continues to grow, the role of these valves in industry will remain crucial. Whether for maintaining efficiency, managing operational pressures, or ensuring precise control, Rexroth Valves offer a trusted solution beloved by industries worldwide. Their ongoing innovations reflect a commitment not only to meeting industry demands but also to leading advancements in hydraulic technology. In a rapidly evolving industrial landscape, investing in Rexroth Valves means choosing a pathway to enhanced productivity, sustainability, and operational excellence.

Furthermore, looking ahead, the trajectory of hydraulic technology suggests an ongoing push towards even smarter and more efficient solutions. With Rexroth continually developing its product lines, the industry can anticipate even more powerful and integrated hydraulic systems that will tackle the challenges of tomorrow. As more industries embrace the Fourth Industrial Revolution, the utilization of hydraulic valving with advanced features like IoT connectivity will bolster real-time data-driven decisions enhancing overall operational quality and reliability.

The foresight of choosing the right hydraulic system cannot be understated. While selecting Rexroth Valves, companies not only gain access to proven technology but also enter into a partnership with a leader in hydraulic innovation, positioning themselves well for future growth in their respective industries. Ultimately, the integration of Rexroth's hydraulic solutions represents a strategic investment in an organization's efficiency and effectiveness in managing complex hydraulic demands in an increasingly competitive market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!