Rexroth counterbalance valves are critical components in hydraulic systems, providing load-holding and safety functions. As industrial applications demand precision in control and safety, these valves play a pivotal role in maintaining system stability. This article explores their functionality, significance, and the science behind their design and application in diverse mechanical settings.

Rexroth counterbalance valves are essential components in modern hydraulic systems, playing a pivotal role in enhancing safety, efficiency, and performance across a myriad of applications. These valves are specifically engineered to offer superior load-holding capabilities, thereby ensuring operational consistency and stability in dynamic environments. Whether utilized in mobile machinery such as excavators and forklifts or in industrial equipment like presses and lifts, Rexroth counterbalance valves serve a critical function in safeguarding both machinery and operators.

Counterbalance valves serve the crucial role of managing the descent and positioning of loads within hydraulic systems. They achieve this by maintaining a predetermined pressure, which prevents loads from moving erratically. This feature is particularly vital in applications where precision and safety are of utmost importance, such as cranes, aerial lifts, and automated guided vehicles (AGVs). Without counterbalance valves, the risk of accidental load drop or uncontrolled movements increases exponentially, potentially leading to catastrophic machine failures, injury to operators, or damage to surrounding environments.

Moreover, counterbalance valves function effectively by utilizing a balance of pressure that corresponds to the load's characteristics and the desired movement. This intricate control enables the hydraulic system to respond to varying load weights and dynamics seamlessly, ensuring that the equipment operates within its safe limits. In essence, counterbalance valves enhance the overall integrity and reliability of hydraulic systems, leading to improved performance outcomes.

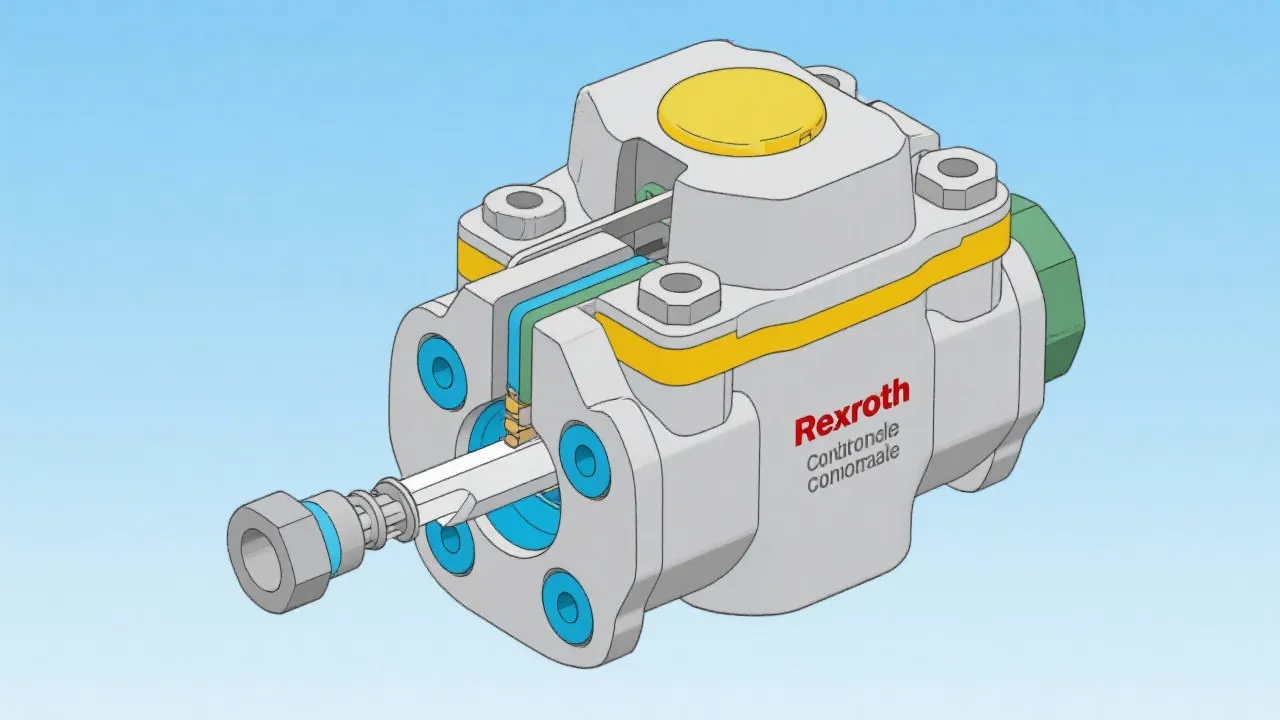

The operational principle of the Rexroth counterbalance valve revolves around the regulation of hydraulic fluid flow relative to the weight and movement of the load. At its core, the valve controls the pressure that opposes the load’s motion, preventing it from descending too quickly. The design of counterbalance valves typically integrates a pilot assist feature, which allows for more nuanced control during variable operating conditions. This mechanism adjusts the flow path based on the changes in pressure, providing increased responsiveness to the load's dynamics.

Furthermore, the precision engineering of these valves ensures minimal leakage, which is crucial for maintaining hydraulic efficiency and system integrity. The robust design also accommodates variations in temperature and fluid viscosity, ensuring that the valves perform optimally in diverse conditions. By incorporating advanced materials and manufacturing techniques, Rexroth counterbalance valves are built to withstand prolonged exposure to challenging environments while delivering consistent performance.

Rexroth counterbalance valves are highly versatile components, finding applications across numerous sectors such as construction, agriculture, manufacturing, and material handling. In the construction industry, these valves are indispensable, particularly in cranes, excavators, and pile drivers, where they ensure safe and controlled material handling. The ability of these valves to provide stability while lifting or lowering heavy loads minimizes the risk of accidents, protecting both operators and bystanders.

In agricultural machinery, counterbalance valves play a significant role in tractors and loaders by ensuring precise control during field operations. Users can confidently manage heavy attachments like plows and harrows without the fear of sudden drops or jerky movements that could damage crops or machinery. Manufacturing equipment, such as injection molding machines and conveyors, also benefits from the inclusion of Rexroth counterbalance valves, leading to more efficient operations and reduced downtime due to safety incidents.

Additionally, the flexibility of counterbalance valves makes them suitable for applications in automated processes where precision handling is crucial. In automated guided vehicles (AGVs), they ensure that payloads are managed effectively while navigating complex pathways within warehouses or distribution centers. The pervasive use of these valves in various applications illustrates their adaptability and the integral role they play in ensuring safe and reliable machinery operation across diverse industries.

Rexroth counterbalance valves come equipped with a range of features that enhance their functionality and usability, making them standout solutions for hydraulic systems. Noteworthy characteristics include:

These features collectively enhance the performance capabilities of hydraulic systems, leading to greater operational efficiency and safety. Rexroth's commitment to innovation ensures that these valves continue to meet the evolving needs of industries worldwide.

| Feature | Description |

|---|---|

| Pressure Control | Adjusts automatically to maintain a safe load descent. |

| Compactness | Designed to fit in tight spaces without compromising functionality. |

| Durability | Built to endure challenging environments and heavy use. |

| Simple Integration | Compatible with a variety of hydraulic systems for easy deployment. |

| Low Maintenance | Engineered for reliability with minimal service requirements. |

| Adjustable Settings | Pressure settings can be customized to suit specific operational needs. |

Implementing Rexroth counterbalance valves in hydraulic systems significantly enhances operational efficiency while drastically reducing safety risks. By precisely controlling hydraulic pressure and fluid flow, these valves help prevent dangerous situations that may arise from machinery malfunctions or improper load handling. Such control contributes to a notably safer working environment, which is paramount in any industry dealing with heavy machinery.

Furthermore, the reliability of counterbalance valves positively impacts productivity. With enhanced stability during load handling tasks, operators can work with confidence, minimizing downtime associated with accidents or equipment failure. The predictable behavior of equipment equipped with such valves allows for smoother operations, leading to increased output and, ultimately, a better return on investment.

Additionally, safety regulations in various industries often demand stringent measures to protect workers and equipment. The ability of Rexroth counterbalance valves to meet these standards serves as an added advantage for businesses looking to align with safety compliance mandates. Overall, the incorporation of these valves into hydraulic systems not only benefits operational performance but also augments the safety and welfare of personnel operating heavy machinery.

Incorporating Rexroth counterbalance valves within hydraulic systems is a strategic choice for enhancing performance and safety across a wide spectrum of industries. These essential components provide superior control over hydraulic operations, allowing for safe handling of heavy loads and minimizing the potential for operational risks. As industries continue to evolve and prioritize the ideals of operational efficiency and worker safety, the demand for reliable and efficient hydraulic solutions like Rexroth counterbalance valves remains strong.

Looking forward, the ongoing technological advancements in hydraulic systems and automation signal that counterbalance valves will continue to play a vital role in achieving enhanced efficiency and improved safety standards. The integration of smart technologies and IoT capabilities within hydraulic systems may pave the way for the next evolution of counterbalance valves. These advancements could lead to even greater precision, monitoring, and control capabilities, further solidifying Rexroth's position as a leader in hydraulic solutions.

In conclusion, the strategic implementation of Rexroth counterbalance valves supports the seamless functioning of equipment across various sectors while showcasing the importance of hydraulic control in today's industrial landscape. Whether in the hands of skilled operators or integrated into automated systems, these valves ensure that safety and efficiency go hand in hand, fostering a new era of productivity and reliability in hydraulic machinery operations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!