Rexroth Counterbalance Valves play a crucial role in hydraulic systems, offering stability and control in various industrial applications. Renowned for their precision and reliability, these valves are essential for managing the pressure and flow of hydraulic fluids, ensuring operational efficiency and safety across different sectors, from construction to manufacturing.

In the ever-evolving realm of hydraulic systems, Rexroth Counterbalance Valves stand out as vital components that ensure fluid control and safety. These valves are designed to maintain a preset pressure within hydraulic cylinders, preventing unintentional movements, especially under load conditions. Hailing from Bosch Rexroth's illustrious line of hydraulic solutions, these counterbalance valves are lauded for their precision, durability, and efficiency. The fundamental essence of these valves lies in their ability to provide a safety net in hydraulic applications where loads need to be controlled with utmost care.

As industries across the globe continue to embrace automation and more sophisticated machinery, the role of hydraulic components, particularly counterbalance valves, becomes increasingly significant. Counterbalance valves not only help in maintaining stability but also enhance the overall safety of hydraulic systems. With the increasing demands of modern machinery, understanding the specifications, benefits, and applications of these valves is crucial for engineers, manufacturers, and maintenance personnel alike.

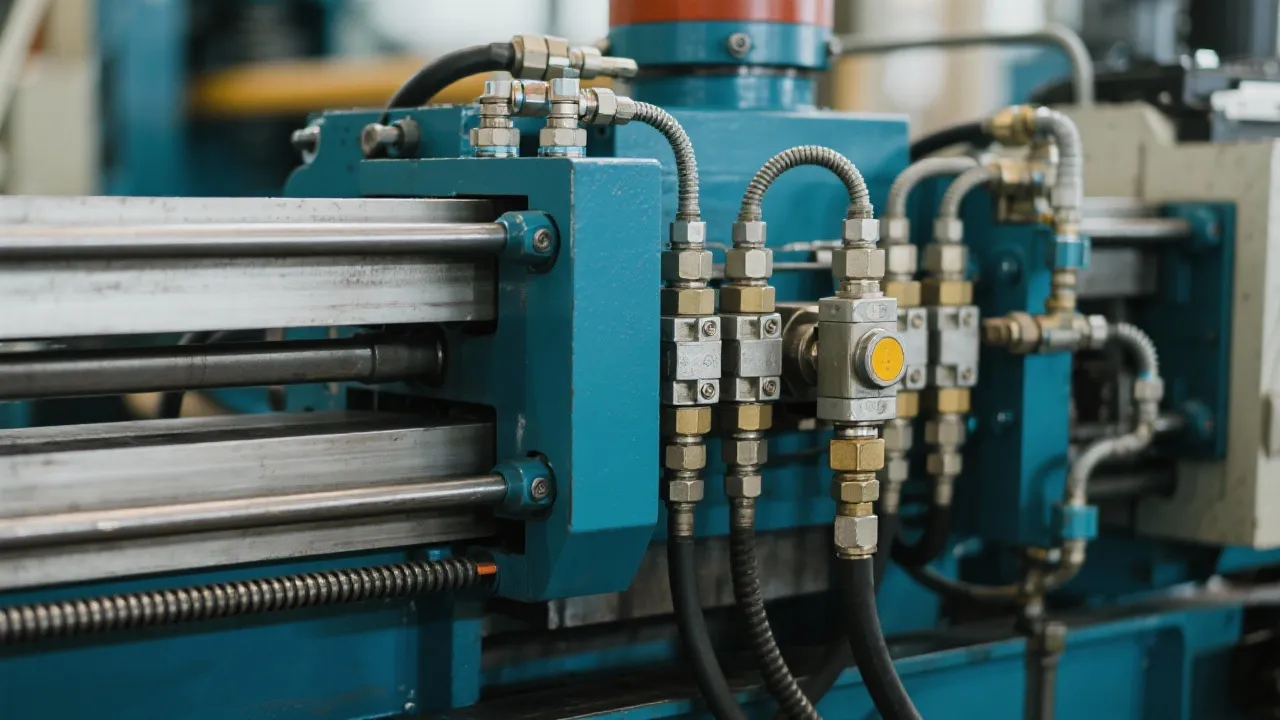

Rexroth Counterbalance Valves are engineered to provide stability within various hydraulic systems. These components are pivotal in applications that require holding or controlling loads, preventing them from falling or lowering due to gravity or other factors. By integrating these valves, industries can ensure seamless operations while maintaining safety. The robustness and design of Rexroth valves make them suitable for a myriad of sectors, including construction machinery, material handling, and mobile equipment.

The use of Rexroth Counterbalance Valves goes beyond mere functionality. They represent a commitment to safety in hydraulic operations. As loads move in unpredictable ways, especially in heavy machinery, the deployment of these valves can significantly mitigate risks associated with hydraulic failures, equipment malfunctions, or operator miscalculations. With the safety of workers often at the forefront of industrial concerns, Rexroth valves afford peace of mind in environments where every second counts and every movement could mean the difference between safety and disaster.

| Feature | Rexroth | Other Brands |

|---|---|---|

| Durability | High | Varies |

| Precision Control | Exceptional | Often Standard |

| Cost Efficiency | Competitive | Varies widely |

| Global Support Network | Extensive | Limited |

When comparing Rexroth Counterbalance Valves to those of other brands, it becomes evident that Rexroth maintains a competitive edge due to its commitment to quality and performance. Users often note that while other brands may offer similar products, the level of precision and customer support provided by Rexroth is unparalleled. This is particularly crucial in industries where downtime can lead to significant financial losses. The Rexroth global support network ensures that assistance is always available, minimizing disruptions and maintaining operational efficiency.

The integration of Rexroth Counterbalance Valves is seamless across various platforms due to their universal design and adaptability. Their primary application is in machines that require a controlled descent, safeguarding against potential drop incidents. They complement the dynamic requirements of forklifts, cranes, and loaders perfectly, ensuring that heavy loads are handled with care and precision.

Beyond the conventional applications, Rexroth valves find utility in a diverse array of sectors such as aerospace, automotive manufacturing, and renewable energy industries. In aerospace, for instance, precision hydraulic control is critical during flight operations, making the use of counterbalance valves vital for maintaining stability in moving components. Similarly, in automotive manufacturing, these valves play a significant role in the assembly lines where heavy parts need to be positioned and held securely without risk of sudden movement.

The adaptability of these valves means they are also suitable for mobile applications, where space constraints and varying load conditions can present challenges. Construction equipment such as excavators and bulldozers significantly benefit from the use of Rexroth Counterbalance Valves. They allow operators to lift and maneuver heavy equipment while maintaining control over the descent of loads, which is vital in preventing accidents at construction sites.

Proactive maintenance is key to extending the lifespan of Rexroth Counterbalance Valves. Regular inspection and cleaning, coupled with timely replacement of worn-out components, ensure optimal performance. Users are advised to follow manufacturer guidelines for servicing, engaging with approved service providers for any technical assistance.

A maintenance routine should ideally include checking for leaks, assessing for signs of wear, and ensuring that the hydraulic fluid levels are adequate. Over time, dirt and debris can accumulate, causing the valve to function less efficiently. Establishing a routine cleaning schedule and adhering to best practices for hydraulic fluid care can prevent contamination and subsequent damage to the valve and associated components.

While Rexroth valves are built to endure rigorous conditions, their maintenance is essential to prevent catastrophic failures that can occur when components are neglected. Training personnel in the proper handling of these components, along with conducting audits on service protocols, can ultimately lead to enhanced safety and reduced operational costs.

In essence, Rexroth Counterbalance Valves are an indispensable component in the world of hydraulics, delivering unmatched reliability and control. As industries advance, these valves provide an assurance of safety and efficiency, solidifying Bosch Rexroth's standing in the hydraulic solutions arena. The foresight of integrating such components into hydraulic systems reflects the ongoing commitment to safety, efficiency, and innovation in manufacturing and operational protocols.

With a legacy built upon quality and precision, Rexroth continues to innovate and enhance the functionalities of their counterbalance valves, adapting to the needs of modern industries. As applications evolve and the demands on hydraulic systems grow, these valves stand as a testament to the pivotal role that engineering excellence plays in achieving operational safety and efficiency. Indeed, in a world where heavy machinery operates under rigorous conditions, Rexroth Counterbalance Valves are not just components; they are cornerstones of a safe and effective hydraulic system.

Through careful selection, installation, and maintenance, the integration of Rexroth Counterbalance Valves can greatly enhance the longevity and effectiveness of hydraulic operations, underscoring their importance in safeguarding both equipment and personnel in various industrial settings. By leveraging their advantages, industries can drive their operational success while upholding the highest safety standards, ensuring that they continue to flourish in the face of increasing challenges and demands.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!