Explore the significance of Rexroth Modular Valves, pivotal components in hydraulic systems worldwide. These versatile valves enhance operational efficiency by enabling flexible system configuration and reliability. This comprehensive guide dives into their functions, applications, and the benefits they bring to various industrial sectors, ensuring optimal performance across hydraulic systems.

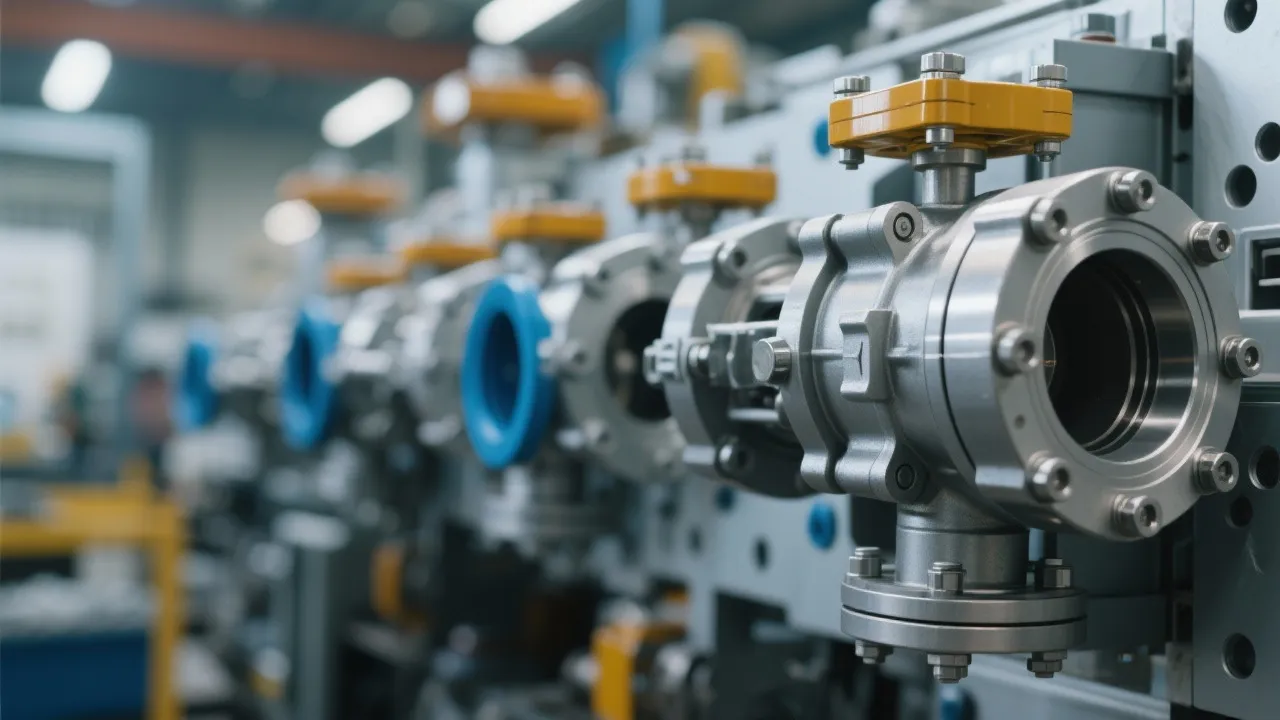

Rexroth Modular Valves are essential components in hydraulic systems, known for their adaptability and efficiency in various applications. These innovative valves are engineered to provide dynamic solutions that can seamlessly integrate into complex hydraulic circuits. Often found in manufacturing and industrial settings, these valves allow for flexible system configurations, which is crucial for meeting diverse operational needs. The modular design facilitates ease of maintenance and scalability, making them a preferred choice in numerous industries, from automotive to aerospace and beyond. This introduction provides a comprehensive overview of the foundational role that Rexroth Modular Valves play in modern hydraulic systems.

At the core of any advanced hydraulic system lies its ability to control fluid flow and pressure accurately. Rexroth Modular Valves excel in this regard, offering precision and reliability. Their modular nature means they can be easily integrated into existing systems or reconfigured for new applications without extensive downtime or hefty modification costs. This aspect of modularity allows engineers and technicians to directly address specific challenges within their hydraulic systems, creating tailored solutions for distinct operating environments without the need for complete overhauls.

Moreover, these valves are built with advanced technologies such as proportional valve technology, which adjusts the flow and pressure in response to varying input signals. This not only enhances control but also leads to significant energy savings as the system can operate in an optimal manner. The responsiveness and efficiency of Rexroth Modular Valves are vital, especially in environments where split-second decisions and actions can dramatically impact productivity and operational safety.

Rexroth Modular Valves are integral in sectors ranging from automotive manufacturing to aerospace, where precise hydraulic control is paramount. For instance, in construction machinery, Rexroth Modular Valves ensure the smooth operation of excavators and loaders by handling high pressures and rigorous use conditions. These valves facilitate the precise control of lifting and lowered loads, ensuring safety and efficiency during operations.

Additionally, in the energy sector, these valves contribute to the efficiency and safety of equipment in power plants by managing critical flow parameters. Their applications in wind turbine gearboxes and hydraulic systems for solar panel tracking mechanisms highlight their versatility. In the food and beverage industry, Rexroth Modular Valves are used in machinery for ingredient mixing and packaging processes, ensuring hygienic and efficient production lines. Each application showcases the adaptability of modular valves, demonstrating their ability to meet industry-specific requirements effectively.

The primary advantages of using these valves include increased operational efficiency and enhanced system control. They allow for easy customization and expansion, which ensures that businesses can adapt to evolving technological demands and production goals. The capability to streamline operations without incurring extensive costs makes them an economical choice for many organizations.

Another benefit is the system’s capacity for diagnostics. Many Rexroth Modular Valves come equipped with intelligent electronics that provide real-time data about the system’s performance. This data can predict failures before they occur, allowing for proactive maintenance strategies. Thus, organizations can optimize their production schedules and minimize unexpected downtimes, contributing significantly to productivity improvements.

Additionally, the reliability of Rexroth products means reduced downtime and maintenance costs, which contributes to improved overall productivity. The durability of these valves also means they have a longer operational lifespan, ensuring that companies capitalize on their investment over extended periods. Moreover, the ease of access to components enhances maintenance efficiency, allowing technical teams to replace or repair parts without major disruptions to operations.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Assembly lines and testing equipment | Precision control, adaptability |

| Aerospace | Flight simulators and testing rigs | High reliability, safety |

| Construction | Machinery and vehicle hydraulics | Durability, strength |

| Energy | Power generation systems | Efficiency, cost reduction |

| Food & Beverage | Ingredient mixing and packaging | Hygiene, precision |

What are the primary features of Rexroth Modular Valves?

Rexroth Modular Valves offer modular flexibility, high durability, and precise control functions, making them suitable for a range of industrial applications. They often have integrated electronic controls for enhanced functionality and adaptability.

How do these valves contribute to system efficiency?

By allowing easy adjustments and expansions, they reduce downtime and maintenance, leading to higher operational efficiencies and cost-effectiveness. Their design minimizes energy consumption by enabling precise operations that only use the necessary amount of hydraulic power.

What types of Rexroth Modular Valves are available?

There are various types, including directional control, pressure control, and flow control valves, each designed to meet specific operational requirements. Select models may also offer integrated functionalities that combine multiple roles, further enhancing space and efficiency in hydraulic setups.

Rexroth Modular Valves are distinguished by a number of design characteristics that contribute to their versatility and effectiveness in hydraulic systems. The valves typically feature a compact design, with options for valving elements stacked together in a modular arrangement. This allows for configurations that can be optimized based on the specific needs of the application.

Materials used in manufacturing these valves are selected for their strength and longevity, often involving high-quality steel and other alloys that can withstand high pressures and extreme environments. This emphasis on durable materials ensures minimal wear and tear, further enhancing the operational life of the valves.

One of the noteworthy design features is their ability to incorporate various actuation methods, including pneumatic, hydraulic, and electric actuators. This flexibility enables users to select the best actuation type based on their application needs and existing infrastructure.

Furthermore, many models come equipped with diagnostic capabilities, which provide real-time performance data. This functionality allows for continuous monitoring of valve performance, helping to identify potential issues before they escalate into serious problems. By facilitating predictive maintenance, these diagnostic features can significantly reduce total lifecycle costs associated with hydraulic systems.

In the realm of industrial automation, Rexroth Modular Valves can be seamlessly integrated with advanced control systems. This capability is pivotal for creating intelligent, automated hydraulic systems that respond dynamically to operational demands. When integrated with programmable logic controllers (PLCs) or decentralized control systems, these valves enable centralized as well as decentralized control approaches.

Through the use of fieldbus protocols such as CANbus, Profibus, or EtherCAT, Rexroth Modular Valves can communicate with other system components, allowing for coordinated actions across the hydraulic circuit. This interconnectedness enhances system performance, offering the ability to synchronize multiple operations and effectively manage complex processes.

This integration also supports the implementation of Industry 4.0 standards by allowing for data exchange between devices, making it easier to collect information about machine status and performance metrics. As a result, companies can leverage this data for further analysis, continuous improvement of their operations, and even employing techniques such as machine learning to optimize hydraulic performance over time.

As industries globally shift towards more sustainable manufacturing practices, Rexroth Modular Valves have been designed with environmental considerations in mind. One of the key features is their ability to optimize hydraulic fluid usage, significantly reducing waste. This optimization is achieved through precise control of flow rates and pressures, minimizing the amount of hydraulic fluid required for operation.

Additionally, the durable construction of Rexroth Valves means they have a longer service life, contributing to fewer replacements and thus reducing the material waste associated with hydraulic components. Environmental compliance is further ensured through the use of eco-friendly materials and manufacturing processes, aligning with global sustainability standards.

Moreover, by enabling energy efficiency through better control of hydraulic systems, Rexroth Modular Valves play a pivotal role in reducing greenhouse gas emissions tied to industrial activities. The ability to operate at optimal performance levels directly contributes to reduced energy consumption, which not only benefits the bottom line but also aligns with corporate social responsibility (CSR) goals aimed at environmental stewardship.

The field of hydraulics is constantly evolving, and with the push towards automation and smart technologies, the future of Rexroth Modular Valves is promising. Emerging trends highlight the integration of digital twins and advanced simulation technologies, allowing engineers to model hydraulic systems before implementation. This proactive approach enables better design decisions and reduces the risk of operational issues post-installation.

Another trend is the continuous advancement of valve technology through the incorporation of artificial intelligence (AI) and machine learning algorithms. These advancements can lead to even more optimized control strategies, helping businesses maximize performance while minimizing costs and resource use.

Moreover, as renewable energy sources become more prevalent, the demand for hydraulic systems in wind and solar applications will grow. Rexroth Modular Valves will likely be central to developing hydraulic solutions that meet the unique demands of these industries, particularly regarding reliability and performance under varying environmental conditions.

Training and development will also become increasingly important, with more resources being allocated to ensure that personnel are well-versed in the latest technology and methods in hydraulics. As such, Rexroth could enhance its support offerings, providing comprehensive training programs and workshops to help customers and technicians develop the necessary skills to maximize the use of their products.

Rexroth Modular Valves represent a significant investment in the reliability and efficiency of industrial hydraulic systems. Their ability to adapt to different industrial requirements ensures they remain at the forefront of hydraulic technology, offering robust solutions to meet the evolving needs of today's demanding industrial environments. With attributes such as modularity, sustainability, and advanced integration capabilities, these valves not only enhance operational efficiency but also contribute positively to the broader goals of environmental responsibility and technological advancement. As the industries continue to innovate, the role of Rexroth Modular Valves will undoubtedly become increasingly prominent, shaping the future landscape of hydraulic operations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!