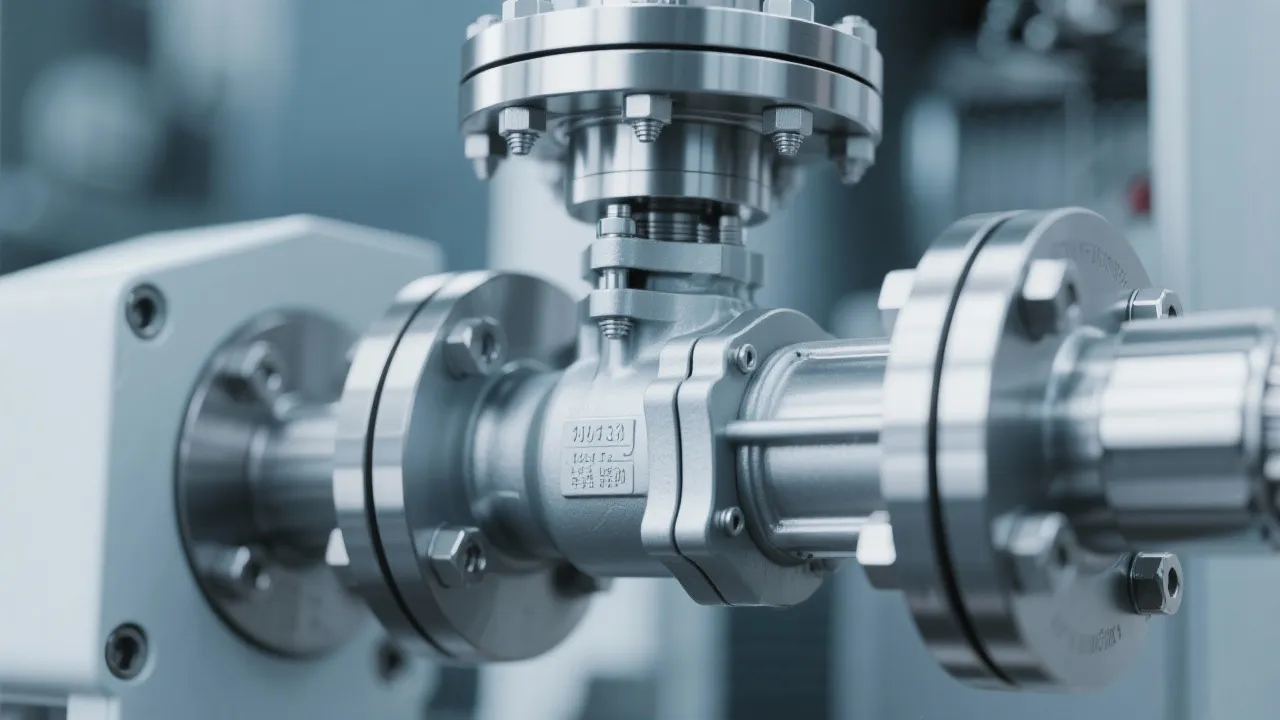

This guide delves into the intricacies of Parker Proportional Valves, essential components in modern fluid management systems. Proportional valves offer precise flow control, integral to various industrial applications, by varying the orifice size and maintaining stable performance. Their deployment in sectors like manufacturing and engineering solutions underscores their importance.

Parker Proportional Valves are integral to fluid control in numerous industries, offering precision in controlling flow rates with a high degree of accuracy. These valves serve a vital function in systems where the control of pressure and flow is crucial. By engaging with electrical signals, they adjust the valve's position to vary the flow or pressure according to situational demands, thereby optimizing operational efficiency. The ability to make real-time adjustments allows for enhanced responsiveness to changing environmental conditions, contributing to better overall system performance.

Understanding the technical specifications of Parker Proportional Valves reveals their superiority in various applications. These valves are designed to understand and adjust to the nuances of flow management, thanks to their ability to handle variable pressure conditions adeptly. The durability and responsiveness of Parker Proportional Valves make them a preferred choice in environments that demand precise control, like manufacturing plants and laboratories. Moreover, the integration of advanced technologies such as digital signal processing allows these valves to maintain optimal operation under fluctuating conditions, ensuring long-term reliability and efficiency.

The key features of Parker Proportional Valves include their robust construction, which guarantees good reliability and performance. These valves come equipped with advanced control systems that ensure low hysteresis, fast response times, and repeatable performance. Additionally, their compact design facilitates easy integration into existing systems without requiring significant modifications. This aspect not only saves time during installation but also reduces downtime associated with system overhauls, making them an economical choice for many industries. The versatility of Parker Proportional Valves extends to their compatibility with various fluid types, including water-based, oil-based, and even aggressive media, making them suitable for a wide range of applications.

| Feature | Benefit |

|---|---|

| Electronically Controlled | Allows precise adjustments and automated control depending on operational requirements. |

| Compact Design | Enables installation in tight spaces without compromising functionality. |

| Durability | Provides good operational performance even in harsh conditions. |

| Low Hysteresis | Ensures accuracy and consistency in output, improving the quality of the operational process. |

| Fast Response Times | Enhances the dynamic performance of the system, allowing for quicker adjustments in operations. |

Parker Proportional Valves find extensive application across different sectors including automotive, aerospace, and manufacturing, where they help modulate fluid dynamics crucial for the equipment function. In automotive manufacturing, for instance, these valves play a critical role in assembly lines, ensuring that hydraulic systems operate smoothly to enhance vehicle production efficiency. Furthermore, they are essential in construction machinery hydraulics, where they manage the precise movements of equipment arms and blades. In the aerospace industry, these valves are utilized in systems requiring exact control of fuel and hydraulic fluid, ensuring optimal performance and safety in flights.

Beyond automotive and aerospace, Parker Proportional Valves serve an important function in the food and beverage industry, where they regulate the flow of liquids with high precision. This precision is vital for maintaining compliance with health and safety standards while optimizing production processes. In chemical processing, these valves manage volatile fluids, ensuring safe handling and transport. The pharmaceutical industry also benefits from the integration of these valves, particularly in processes requiring sterile environments and precise dosage applications.

A prime example of Parker Proportional Valves' efficacy can be seen in an automotive plant nearby, where these valves were integrated into their hydraulic systems. The result was significant improvement in the vibration isolation process, leading to enhanced equipment lifespan and production output. This case underscores the role of precision fluid control in improving operational success and product quality. The plant reported a 20% increase in throughput after the installation of Parker Proportional Valves, primarily due to faster cycle times and reduced downtime related to system adjustments. Moreover, the ability to dynamically tweak fluid control based on real-time data significantly reduced waste, contributing to both cost savings and a smaller environmental footprint.

In another instance, a large-scale manufacturer of plastic components integrated Parker Proportional Valves into their injection molding machines. The valves allowed for precise control of hydraulic pressure during the injection process, resulting in higher quality components and reduced reject rates. These improvements culminated in better resource management and increased profitability for the manufacturer. This highlights how the strategic application of proportional valves can lead to significant advancements in production processes across various industries.

In conclusion, Parker Proportional Valves are indispensable in today's industrial landscape. As industries continue to lean towards automation and precise control systems, the demand for these advanced valves will only increase. Whether it's enhancing the efficiency of a manufacturing unit or ensuring precision in automotive assembly lines, Parker Proportional Valves serve as a testament to technological advancement in industrial applications. Looking ahead, the growing trend towards smart manufacturing and IoT-enabled systems points to even greater relevance for Parker Proportional Valves. As manufacturers increasingly embrace Industry 4.0, the versatility and adaptability of these valves will play a critical role in achieving smarter, more efficient production processes. Companies that invest in this technology now can expect to stay ahead of the competition, leveraging enhanced capabilities that drive both productivity and quality.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!