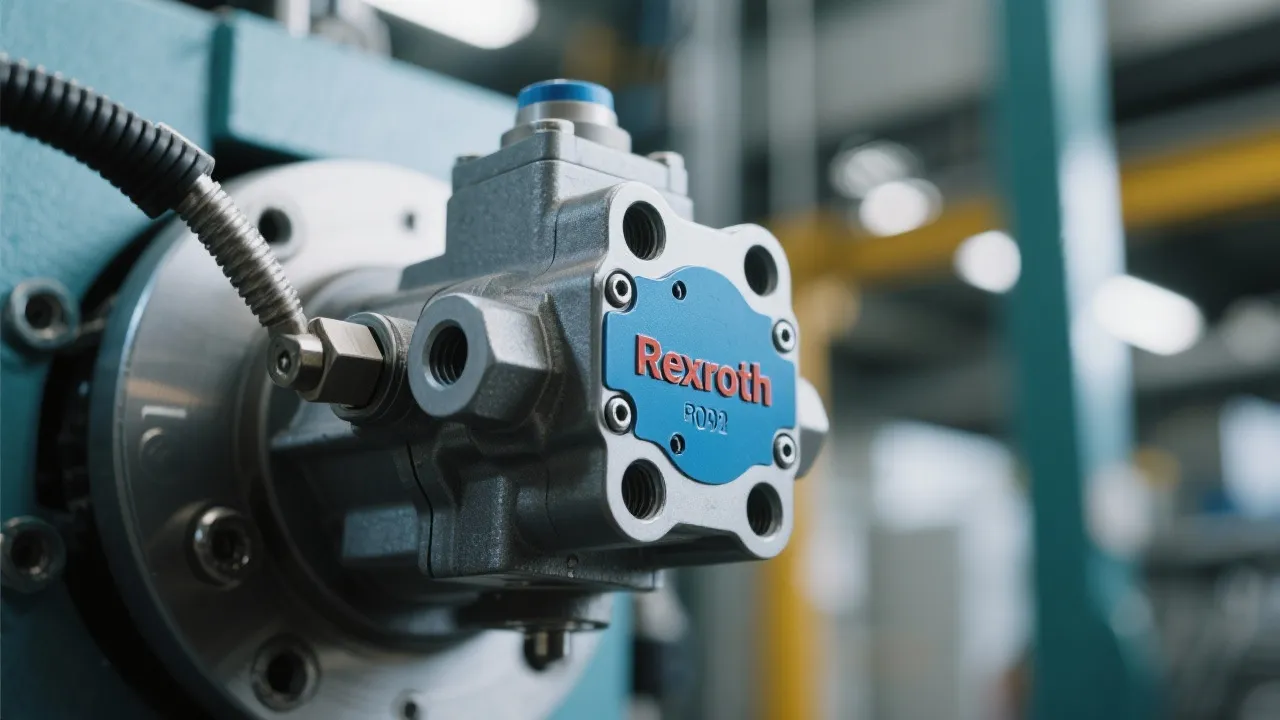

This article delves into Rexroth poppet valves, exploring their functionality, significance, and applications in various industries. Rexroth is renowned for its precision-engineered hydraulic solutions, and the poppet valve is a crucial component in many mechanical systems, providing reliable performance and control. The article further discusses their impact on enhancing industrial efficiency and safety.

The industrial landscape is evolving rapidly, demanding high performance and efficiency from its components. Among these, the Rexroth poppet valve stands as a paragon of efficiency and precision. Known for its robust design, the poppet valve plays a pivotal role in controlling fluid flow within hydraulic systems, showcasing its importance in various sectors such as automotive, manufacturing, and aerospace. Engineers and system designers continually seek solutions that not only meet requirements but also exceed operational expectations, and Rexroth’s offerings in poppet technology exemplify that ambition.

Poppet valves are a type of directional control valve that regulate the flow of fluid within a system. They are characterized by their tight sealing capabilities and swift response time. Rexroth, a leading provider of hydraulic solutions, offers poppet valves that are specifically designed to manage high-pressure applications, providing both reliability and longevity. These valves utilize a poppet mechanism that opens and closes to allow or obstruct fluid flow, making them ideal for precision control. The operational principle is straightforward: when the poppet is lifted, the passage for the hydraulic fluid opens; when it descends, the flow is halted, thereby ensuring that the system operates effectively and according to the desired specifications.

Rexroth poppet valves are utilized across numerous industries, each benefitting uniquely from their deployment:

The standout features of Rexroth poppet valves include:

| Feature | Description |

|---|---|

| High Flow Capacity | Allows for significant flow rates while maintaining control, crucial for applications requiring rapid actuation. |

| Tight Sealing | Ensures no leakage, maintaining system integrity and efficiency, which is vital in high-stakes applications. |

| Corrosion Resistance | Suitable for use in environments exposed to aggressive substances, giving operators peace of mind in harsh working conditions. |

| Temperature Tolerance | Designed to function effectively under extreme temperatures, suitable for both high and low thermal environments. |

| Modular Design | Facilitates easy integration into existing systems, providing options for future enhancements or modifications. |

When installing Rexroth poppet valves, certain best practices can enhance their operational longevity and reliability. Here are some key considerations:

Q1: What makes Rexroth poppet valves reliable?

A: Rexroth uses advanced engineering and high-quality materials in the manufacture of their valves, providing consistent performance under various conditions. The rigorous testing processes ensure that each valve meets industry standards, which reinforces their reputation for reliability.

Q2: Can these valves be used in high-temperature environments?

A: Yes, Rexroth poppet valves are designed to operate efficiently in high-temperature settings, thanks to their robust construction and materials. They are ideal for applications where thermal stability is essential, such as in aerospace and automotive contexts.

Q3: How do these valves enhance system efficiency?

A: They streamline fluid flow with minimal resistance, reducing energy consumption and improving the overall efficiency of the hydraulic system. This efficiency translates into cost savings and lower energy demands, supporting sustainable practices in industrial applications.

Q4: Are Rexroth poppet valves customizable?

A: Absolutely. Rexroth offers possibilities for customization based on operational specifications, allowing users to select features that best suit their particular application.

Q5: How can I ensure longevity in using Rexroth poppet valves?

A: Regular maintenance checks, including monitoring the condition of hydraulic fluid and inspecting seals, will help prolong the life of these valves. Proper installation and adherence to operational guidelines also play key roles in their longevity.

As technology progresses, the evolution of poppet valves continues to be influenced by advancements in automation and control systems. Industry trends indicate a shift towards more electronically controlled hydraulic systems, where poppet valves coexist with sensors and smart technologies. This integration allows for enhanced monitoring and automation, which not only enhances system efficiency but also provides valuable real-time data for operational improvements.

Smart Valves: The emergence of smart technology is leading to the development of intelligent poppet valves that can self-diagnose and report their operational status. This can significantly reduce maintenance overheads and downtime, ensuring operational continuity.

Digital Twin Technology: Utilizing digital twins in hydraulic systems is on the rise, allowing for simulation and analysis of valve functionality under various operating conditions. This technology aids engineers in optimizing designs before physical installations, reducing costs, and improving efficiency through predictive maintenance strategies.

As industries continue to evolve, the demand for reliable and efficient components like the Rexroth poppet valve remains critical. With their advanced features and versatility, these valves not only uphold the highest standards of performance but also drive innovation in the engineering sector. In an age where precision engineering and efficiency are paramount, Rexroth poppet valves exemplify the fusion of reliability and cutting-edge technology, making them indispensable to modern hydraulic systems. Continued investment in research and development will only enhance their capabilities, ensuring that they meet future demands of the industries they serve.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!