This article explores Rexroth poppet valves, vital components in fluid control systems, known for their robust design and versatility. Primarily used in hydraulic systems, these valves perform essential functions that influence operational efficiency by controlling fluid flow, pressure, and direction. Their application across industries showcases their reliability and engineering excellence.

Rexroth poppet valves are integral to modern hydraulic systems. Their chief function is to manage fluids' flow, pressure, and direction, thereby ensuring optimal system performance and longevity. Known for their robustness and precision, these valves are vital in industries ranging from manufacturing to energy and transportation. Understanding their operational principles and benefits can help in maximizing the effectiveness of hydraulic systems, leading to improved operational efficiency and cost savings.

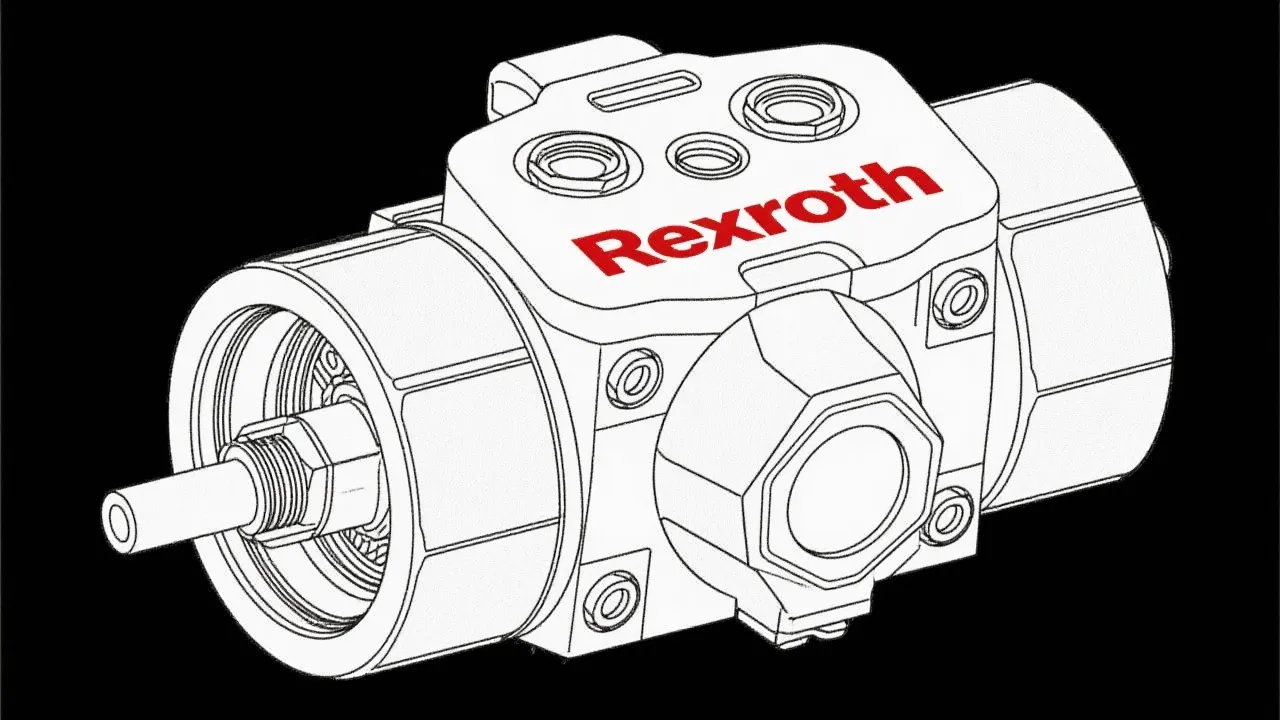

Rexroth, part of the Bosch Group, is synonymous with excellence in engineering and innovative hydraulics. Their poppet valves stand out for their reliability, durability, and efficiency, making them a preferred choice for engineers and operators worldwide. These valves are designed to withstand high pressure and variable loads, offering precise control over complex hydraulic systems. Furthermore, the company is rooted in a tradition of technological advancement, ensuring that their products continuously meet the evolving needs of various industries.

The innovation behind Rexroth poppet valves is a reflection of their commitment to quality and performance. Utilizing state-of-the-art manufacturing techniques, these valves are crafted with precision to ensure that they deliver high performance under demanding conditions. Moreover, Rexroth invests heavily in research and development, striving to perfect their designs and introduce new technologies that enhance the functionality and reliability of their products in the field.

Rexroth poppet valves find applications in diverse industries due to their versatility. In the manufacturing sector, they help in the precise control of machinery, ensuring consistent product quality. Their role in ensuring that hydraulic machinery operates smoothly translates into minimized downtime and maximized production rates, which are crucial for maintaining competitiveness in today's fast-paced market.

In the automotive industry, these valves contribute to smoother operation and energy efficiency in vehicles. By efficiently controlling fluid dynamics within vehicle hydraulic systems, they enhance responsiveness and power efficiency, factors that are increasingly critical as automakers strive for greener technologies. The integration of Rexroth poppet valves in hybrid and electric vehicles is a notable advancement, helping reduce energy losses and improve overall vehicle efficiency.

The energy sector utilizes them for reliable performance in oil and gas extraction and renewable energy systems. In oil and gas operations, the valves play essential roles in ensuring safety and reliability during extraction processes, as they help manage high-pressure fluids that are characteristic of drilling operations. Similarly, in renewable energy, particularly wind and solar power installations, Rexroth valves aid in fluid control systems that optimize resource use and operational efficiency.

Rexroth's poppet valves come with a variety of technical specifications to meet different industrial requirements. These specifications include different flow rates, pressure levels, and connection types. A key feature is the poppet design, which ensures a tight seal when closed, preventing leakages and ensuring system integrity. Additionally, these valves can be operated both manually and electronically, offering flexibility in control mechanisms.

The technical diversity of Rexroth poppet valves allows businesses to customize their hydraulic systems based on specific needs. For example, the ability to select from various flow rates ensures that engineers can match the valve’s performance characteristics to the demand of specific applications, whether in material handling equipment or hydraulic presses. Furthermore, Rexroth provides detailed performance curves and specifications, enabling engineers and technicians to make informed decisions regarding valve selection that aligns with system requirements.

In terms of materials, Rexroth poppet valves are typically constructed from high-quality metals and alloys that enhance durability and corrosion resistance. These materials help in extending the lifespan of the valves even under harsh chemical and environmental conditions, making them suitable for use not just in standard hydraulic applications but also in industries like pharmaceuticals and food processing where hygiene and resistance to corrosive substances are paramount.

| Feature | Benefit |

|---|---|

| High Pressure Resilience | Ensures consistent performance and system reliability. |

| Versatile Operation | Can be adapted to various control systems and applications. |

| Durable Construction | Long service life, reducing maintenance needs and operational costs. |

| Precision Control | Maintains accurate flow and pressure control, enhancing efficiency. |

| Wide Range of Options | Accommodates diverse industrial applications. |

| Quick Response Times | Enhances operational speed and reduces cycle times. |

| Integrated Safety Features | Prevents system failures and enhances operational safety. |

Proper installation and maintenance of Rexroth poppet valves are vital for maximizing their performance. Installation should be carried out by trained professionals, adhering to manufacturer’s guidelines to ensure correct alignment and connection. Regular maintenance checks, including cleanliness and inspection of seals and connections, are crucial to prevent wear and extend valve life. The environment around the valve should also be taken into consideration; for example, protecting valves from dust, moisture, and extreme temperatures can significantly improve their lifespan.

Implementing a proactive maintenance strategy involving routine inspections and predictive analytics can help identify potential issues before they become critical. This not only reduces unplanned downtime but also helps in planning for spare parts and replacements in advance, ultimately driving efficiency and cost-effectiveness in operations. Moreover, operators should ensure that they have access to comprehensive service manuals and training resources to assist in maintenance procedures.

Specialized software can help technicians monitor valve performance over time, analyzing data and providing insights that guide operational decisions. Such technology enables the optimization of hydraulic systems, ensuring that all components function harmoniously. For Rexroth valves, understanding how to utilize diagnostic tools can aid in troubleshooting issues rapidly, ensuring continued system reliability.

Rexroth poppet valves are widely available through authorized distributors and suppliers. Their market presence is reinforced by a strong network of partners and service centers, ensuring easy access to products and after-sales support. This strategic distribution ensures minimal downtime and rapid deployment for industrial projects. With the integration of digital purchasing platforms, customers can now conveniently access product catalogs online, compare specifications, and make informed purchasing decisions quickly.

The global reach of Rexroth guarantees that customers in various regions benefit from the same high-quality standards and innovative technology, regardless of local market conditions. Additionally, the company continually assesses market requirements, allowing them to adapt to emerging trends and challenges, such as increasing demands for automation in various sectors. This adaptability is key to maintaining relevance in an increasingly competitive landscape.

As industries evolve, Rexroth remains committed to developing new products that meet emerging needs such as sustainability, energy efficiency, and automation. This commitment includes not only expanding their poppet valve line but also exploring cutting-edge technologies such as IoT and Industry 4.0 to improve hydraulics functionality in smart environments.

Q: What makes Rexroth poppet valves unique?

A: They combine precision engineering with robust design, making them reliable in diverse applications. Their adaptability to custom requirements further enhances their uniqueness, allowing for the development of tailored solutions.

Q: How do they handle high pressure?

A: Their durable construction and design optimize them for resilience in high-pressure environments, withstanding forces that come from fluid behaviors in variable load situations. Innovative sealing technologies also play a critical role in their performance.

Q: Can they be used in energy applications?

A: Yes, they're well-suited for both conventional and renewable energy systems, with functionality across oil and gas extraction, as well as in systems harnessing solar and wind energy.

Q: Are there maintenance requirements?

A: Regular inspections and maintenance are recommended to enhance performance and longevity. A systematic maintenance schedule can help prevent failures and ensure that the valves operate as intended.

Q: How can one ensure optimal performance from Rexroth poppet valves?

A: By understanding the specific operational demands of an application and ensuring that installation guidelines are strictly followed, operators can significantly enhance performance. Employing proactive maintenance strategies and utilizing technology for diagnostics also contribute to achieving optimal results.

In conclusion, Rexroth poppet valves are a testament to the synergy of engineering prowess and practical design, playing a pivotal role in enhancing the performance and reliability of hydraulic systems across various industries. By providing unparalleled precision, durability, and adaptability, these valves lead to significant operational efficiencies and cost savings, marking them as an essential investment for businesses aiming to remain competitive in an increasingly complex market landscape. As industries continue to innovate and evolve, staying informed about advancements in valve technologies and practices will be crucial for ensuring continued operational success and sustainability.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!