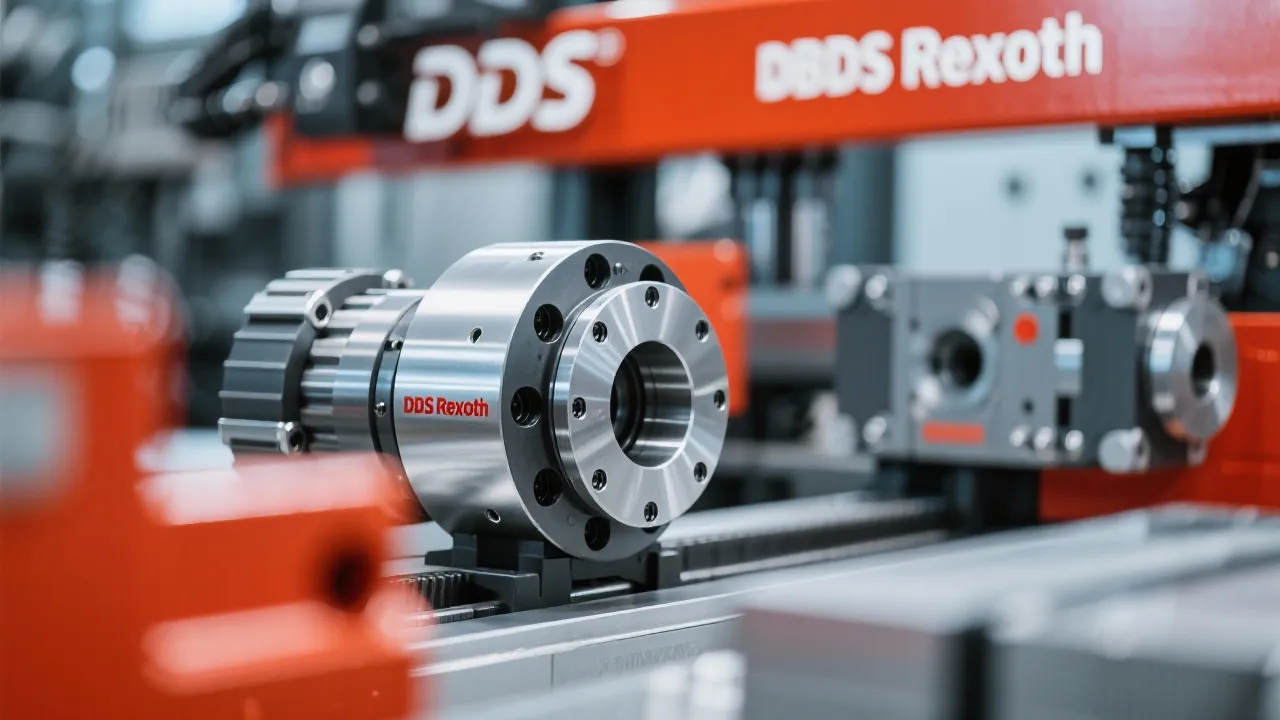

Dbds Rexroth systems are pivotal in modern hydraulics, providing precision and efficiency in various industrial applications. Recognized globally, Rexroth hydraulic components, including valves and pumps, are known for their durability and innovative designs that enhance productivity and reliability across sectors. This guide delves into the nuances of these systems and their impact on industry standards.

Dbds Rexroth stands as an emblem of quality and innovation in the field of hydraulics. As a global leader, Bosch Rexroth offers a range of hydraulic solutions that have drastically influenced how industries approach mechanical and fluid power. Their products, renowned for robustness and cutting-edge technology, play a crucial role in applications ranging from manufacturing to industrial automation. This article delves deeper into the defining features of Dbds Rexroth systems, exploring their significance, practical applications, and the impact they have made across industries as varied as automotive, aerospace, and construction.

Hydraulic systems are integral to machinery, enabling efficient operation and control. Dbds Rexroth products, including valves, cylinders, and pumps, possess distinctive characteristics that allow them to effectively manage energy transfer. This capability enhances machine performance while ensuring safety and precision. The smooth operation of hydraulic systems minimizes downtime, optimizes energy usage, and enables seamless integration with other technologies, thus significantly contributing to overall operational efficacy.

Hydraulic components, when selected and implemented successfully, allow for more adaptable and responsive machinery capable of handling varying loads and operational conditions. With advanced capabilities, Dbds Rexroth hydraulic solutions help organizations save on operational costs while reducing system wear and tear, ultimately extending the lifecycle of both machinery and components.

In addition to these core features, Rexroth's emphasis on sustainability allows for energy-efficient designs that meet regulatory standards while catering to environmentally conscious markets. This integration of sustainability in product development aligns with the global trend of reducing carbon footprints across industries.

This meticulous approach to implementing Dbds Rexroth systems not only aligns with industry best practices but also lays the groundwork for future enhancements and adaptations in the face of evolving technological landscapes.

| Feature | Dbds Rexroth | Alternative Brands |

|---|---|---|

| Precision | High accuracy in operation with meticulous attention to detail | Varies based on manufacturer—some brands may offer competitive precision but typically lack the extensive quality checks of Rexroth. |

| Durability | Proven long lifespan; components are rigorously tested under dynamic conditions to ensure reliability | Moderate to high lifespan; however, alternative brands may experience greater variability depending on production techniques. |

| Technological Innovation | Leading-edge tech integration, incorporating AI and machine learning for system optimizations | Varying levels of innovation; while some brands are catching up, Rexroth remains at the forefront of integrating next-generation technologies. |

This comparison illustrates that while alternative brands offer viable options, the comprehensive quality across precision, durability, and innovation firmly positions Dbds Rexroth as an industry leader. Their consistent investment in R&D ensures they stay ahead of trends, making them a reliable choice for businesses seeking long-term solutions.

As industries increasingly face pressures to optimize processes and adopt sustainable practices, hydraulic systems must evolve. Dbds Rexroth is more than equipped to lead this evolution through continued innovations in their product line. Future advancements are expected to include further integration of IoT, automation technologies, and AI to create systems that offer not only enhanced usability but also predictive and autonomous functionality.

For instance, predictive maintenance analytics powered by machine learning algorithms may forecast potential failures before they occur, allowing companies to act proactively rather than reactively. This shift will save time and resources while minimizing downtimes and maximizing productivity. Additionally, the focus on energy-efficient components will further enhance the environmental sustainability of operations across the board.

Lastly, as remote access and control become standard fixtures in industrial environments, Dbds Rexroth is likely to advance their connectivity solutions, allowing operators to manage systems from anywhere in real-time, enhancing the operational flexibility and responsiveness of organizations.

Dbds Rexroth systems have revolutionized hydraulic technologies, offering superior precision, durability, and innovation. Their wide range of applications across different sectors underscores their importance in powering modern industry infrastructures and boosting operational efficiency. By selecting Dbds Rexroth, industries gain a partner committed to excellence and future-ready solutions.

The robust architecture and intelligent design of their systems not only cater to current industrial demands but also prepare companies to tackle the challenges of the future. As we look forward to a more automated and efficient industrial landscape, Dbds Rexroth will undoubtedly play a central role in shaping how hydraulic systems evolve, ensuring they meet the needs of a rapidly changing world.

Thus, by integrating Dbds Rexroth technology into various applications, industries not only stand to benefit from immediate operational improvements but also strategic advancements that will solidify their competitive edge well into the future.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!