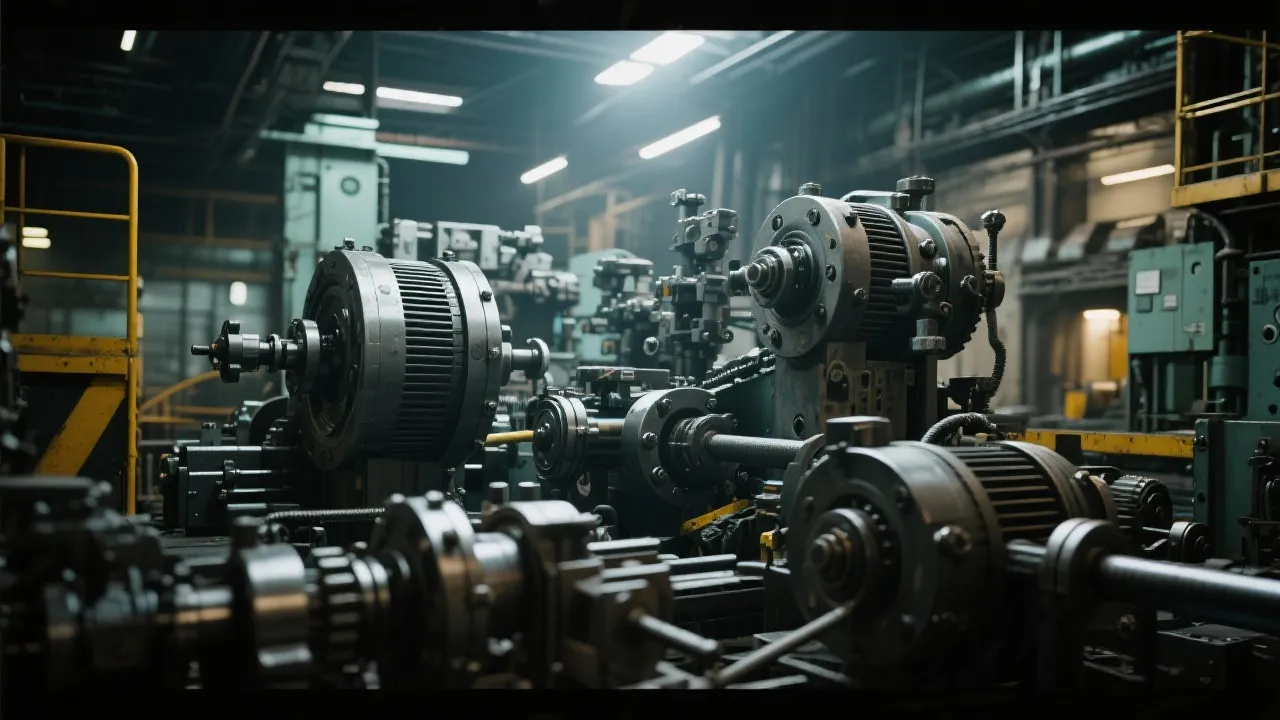

This article delves into the details of Dbds Rexroth, focusing on its importance in industrial applications. Dbds Rexroth, a reputable name in the hydraulic components industry, offers solutions critical for the efficiency and longevity of various machineries. Through expert insights and a comprehensive analysis, this guide aims to provide clarity on its functionalities, advantages, and industry relevance.

In the world of industrial hydraulics, few names resonate as robustly as Dbds Rexroth. Renowned for their cutting-edge hydraulic systems and components, Dbds Rexroth plays a pivotal role in enhancing the operational efficiency of machinery across numerous industries. Established decades ago, the company has consistently invested in research and development, embracing innovation to align with the rapidly evolving demands of global industrial sectors. This article aims to provide an in-depth understanding of Dbds Rexroth's offerings, particularly focusing on their range of hydraulic components.

Hydraulic systems are integral to modern machinery, transforming fluid power into mechanical power, facilitating motion, and controlling force. These systems use incompressible fluids to transmit power efficiently, making them critical in heavy machinery, robotics, and CNC applications. Dbds Rexroth’s hydraulic solutions are designed with these principles in mind to optimize performance and increase the efficiency of production processes in various industries such as manufacturing, construction, automotive, marine, and even aerospace. The versatility of hydraulic systems allows them to operate in a wide range of applications, from simple actuation processes to complex automated systems, which makes companies like Dbds Rexroth pivotal in these industries. Their extensive portfolio of products includes hydraulic pumps, valves, cylinders, power units, and more, each designed to meet the diverse needs of today’s industrial operators.

Dbds Rexroth components are celebrated for their durability and precision. Built to withstand harsh environmental conditions, these components ensure consistent functionality, even in the most demanding applications. The materials used in manufacturing these components are chosen for their resilience and ability to resist wear and corrosion, extending the lifespan of critical machinery. Moreover, their innovative design minimizes maintenance requirements and maximizes uptime—crucial for any industrial operation. Advanced manufacturing techniques and rigorous testing protocols further enhance the reliability of Dbds Rexroth products. For instance, hydraulic cylinders manufactured by Dbds Rexroth undergo extensive quality assurance processes to guarantee that they perform at optimum levels. The integration of technology such as finite element analysis during design stages means that potential weaknesses are identified and addressed early, ensuring only the best products reach the end user.

The advantages of integrating Dbds Rexroth into machinery are numerous, including enhanced energy efficiency, reduced operational costs, and prolonged equipment lifespan. Energy-efficient hydraulic components contribute to lower energy consumption, which translates to significant cost savings for companies in the long run. Enhanced modularity of Dbds Rexroth components allows for easy upgrades and scalability, accommodating future technology advances or changes in production volumes. Additionally, the adaptability of Dbds Rexroth components allows them to be seamlessly integrated into existing systems, offering versatility to industries with diverse needs. Their expert consultation services further help organizations identify the best solutions tailored to their specific applications, ensuring that they operate at peak performance without unnecessary overhead costs.

| Feature | Dbds Rexroth | Competitor A | Competitor B |

|---|---|---|---|

| Durability | High | Medium | High |

| Energy Efficiency | Excellent | Good | Excellent |

| Maintenance Needs | Low | Medium | Low |

| Technology Integration | Advanced | Basic | Moderate |

| Customization Options | Extensive | Limited | Moderate |

| Customer Support | Comprehensive | Good | Basic |

Experts foresee a greater integration of smart technology with hydraulic systems, where components like those from Dbds Rexroth will play a crucial role. The future will see hydraulic systems becoming more automated, with real-time monitoring and adjustments to enhance system efficiency and sustainability. Innovations such as IoT-enabled sensors and predictive maintenance algorithms will allow companies to anticipate failures before they occur, reducing downtime and maintenance costs significantly. Additionally, as industries shift towards sustainability, hydraulic systems are evolving to incorporate environmentally friendly fluids and energy-efficient designs that lower their carbon footprint. There is also an increasing emphasis on hybrid and electro-hydraulic systems, which combine traditional hydraulic functions with electric motors to optimize efficiency and responsiveness.

Dbds Rexroth’s diverse product lineup is one of the key factors contributing to its broad acceptance in the industrial sector. They offer a full range of hydraulic products that cater to various applications, including:

The foundation of any hydraulic system, hydraulic pumps convert mechanical energy into hydraulic energy. Dbds Rexroth manufactures various types of pumps, including gear pumps, piston pumps, and vane pumps. Each pump type is tailored to specific applications, ensuring optimal performance and efficiency. For example, their axial piston pumps are designed for high-pressure applications and can maintain a compact form factor, ideal for advanced machinery that requires space and weight considerations. These pumps can be fine-tuned for performance, making them suitable for intricate hydraulic systems found in aerospace and marine industries.

Hydraulic cylinders act as actuators within a hydraulic system, providing the necessary force to move machinery and equipment. Dbds Rexroth hydraulic cylinders are renowned for their robust construction and precision engineering. They are available in standard and custom configurations to suit specific applications, such as double-acting cylinders for heavy lifting or single-acting cylinders for compact areas. Advanced features in Dbds Rexroth cylinders can include integrated position sensors and cushioning mechanisms to enhance their performance and reduce wear.

Hydraulic valves control the flow and pressure within the system, directing hydraulic fluid where it is needed most. Dbds Rexroth offers a wide range of valves, including directional control valves, pressure relief valves, and flow control valves. Each valve type plays a critical role in maintaining system integrity and performance. The intelligent design of Dbds Rexroth valves allows for rapid response times, precision control, and ease of integration into existing systems, making them a popular choice for automation applications in manufacturing lines.

Dbds Rexroth’s hydraulic power units (HPUs) are self-contained packages that supply hydraulic fluid to hydraulic systems. These units are customizable for various applications, including mobile equipment and stationary machinery. Dbds Rexroth's HPUs are designed for energy-efficient operation and can include features such as variable speed drive technology, which adjusts the motor speed based on system demand, further enhancing energy efficiency and reducing operational costs.

The advent of Industry 4.0 has irrevocably changed the landscape of manufacturing and industrial operations, and hydraulics are no exception. Dbds Rexroth is at the forefront of this transition, capitalizing on smart technology to enhance hydraulic systems' efficiency and reliability. By integrating IoT devices and data analytics into their components, Dbds Rexroth enables operators to monitor system performance in real time, which can lead to improved decision-making and operational strategies. This convergence of operational technology and information technology allows businesses to adapt to market changes swiftly, reduce waste, and optimize their production processes.

Dbds Rexroth is not just a component supplier but also a partner in the success of its clients. They offer comprehensive training programs and support services designed to empower operators and maintenance personnel with the knowledge they need to maximize the performance of hydraulic systems. These training programs cover various aspects, from basic hydraulic principles to advanced troubleshooting and system optimization. This expert knowledge transfers not only increases the reliability of Dbds Rexroth systems but also contributes to the overall skill development of the workforce in industries utilizing hydraulic technology.

With a footprint that spans across continents, Dbds Rexroth possesses the global reach necessary to serve multinational clients effectively while maintaining a local presence that understands regional market dynamics. Their network of local service centers and distributors ensures that clients receive timely support, tailored solutions, and quick access to replacement parts. This combination of global scale and local expertise ensures that businesses have the resources they need to succeed in increasingly competitive environments.

Numerous case studies showcase the effectiveness of Dbds Rexroth hydraulic components across various industries. For instance, in the automotive industry, a major manufacturer integrated Dbds Rexroth hydraulic systems into their assembly line, resulting in a significant increase in production efficiency and a decrease in daily operational downtime. Similarly, in construction, a contractor utilizing Dbds Rexroth hydraulic power units reported a 40% reduction in energy costs while maintaining greater control over machinery operations. Such success stories underline the effectiveness of Dbds Rexroth solutions in delivering tangible improvements in operational performance across diverse sectors.

Dbds Rexroth is distinguished by its commitment to quality, innovation, and adaptability. Their components are engineered to meet the highest standards of efficiency and reliability, making them a preferred choice among industries worldwide. Their dedication to customer service, product support, and flexibility in customization further enhances their reputation in the hydraulics industry.

Yes, one of the key advantages of Dbds Rexroth is the adaptability of their components, which can be customized to meet specific industrial requirements, ensuring optimal integration with existing systems. Through consultation with clients, Dbds Rexroth experts assess the needs of specific applications and propose tailored solutions that meet technical specifications while maintaining budgetary considerations.

Dbds Rexroth actively seeks to reduce the environmental impact of its operations and products. This includes developing energy-efficient hydraulic components that reduce energy consumption during operation. Additionally, they focus on environmentally friendly manufacturing processes and materials, ensuring the lifecycle of their products minimizes ecological footprints. Ongoing initiatives include enhancing recycling efforts and utilizing biodegradable hydraulic fluids where applicable.

Dbds Rexroth offers a comprehensive support system that includes technical assistance, maintenance services, and a robust warranty program. Customers receive continual updates on product performance and can access a wealth of online resources, including manuals, training videos, and troubleshooting guides. Personalized support is also available through a dedicated customer service team that responds promptly to inquiries and concerns.

Dbds Rexroth stands at the forefront of hydraulic innovation, continuously pushing the boundaries of what hydraulic systems can achieve. Their commitment to energy efficiency, reliability, and adaptability makes them an indispensable asset for industries aiming to enhance performance and reduce costs. As technology continues to evolve, Dbds Rexroth remains dedicated to improving their product offerings, ensuring that customers have access to the latest advancements in hydraulic technology. The future of hydraulics looks bright with Dbds Rexroth leading the charge, and industries can look forward to even greater efficiencies and sustainability practices as a direct result of their ongoing contributions to hydraulic engineering excellence.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!