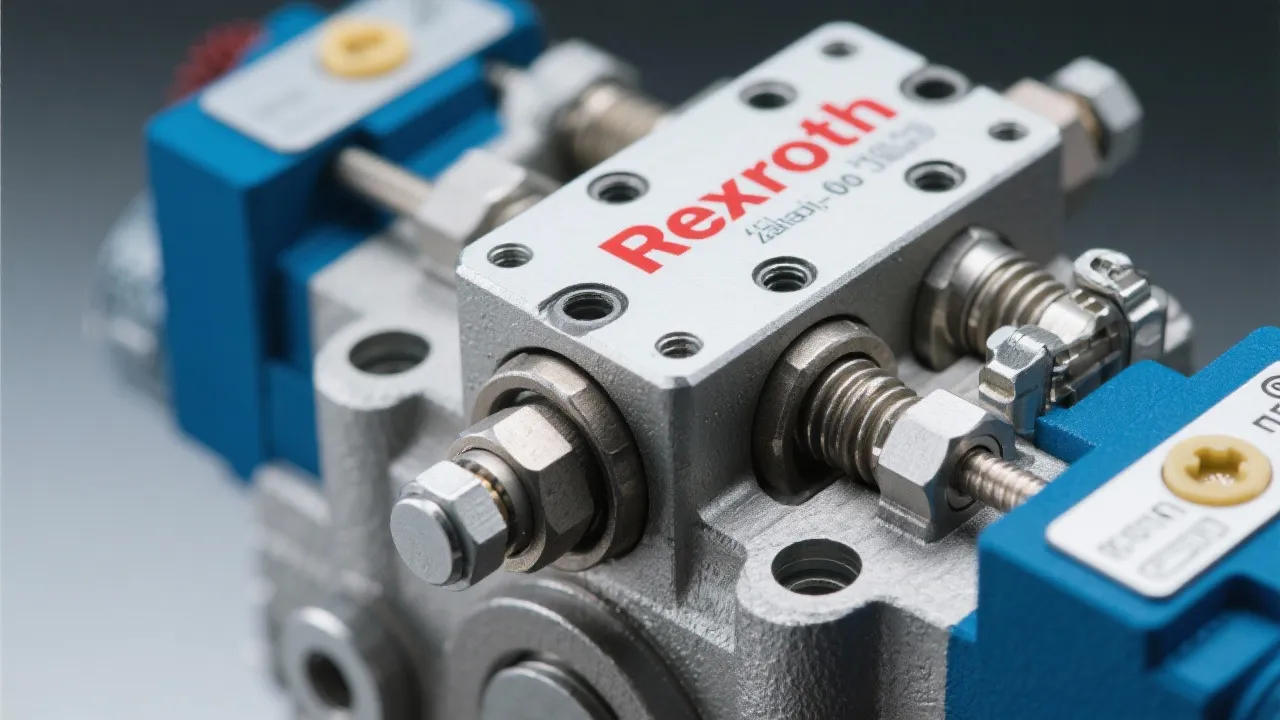

Rexroth modular valves are pivotal components in hydraulic systems, offering versatile and efficient flow control solutions for diverse industrial applications. With a design focused on modularity, these valves enhance system efficiency and reliability, demonstrating Rexroth’s commitment to advanced engineering. This article delves into their function, benefits, and industry applications.

Rexroth modular valves form the backbone of many hydraulic systems by offering precise control over fluid dynamics. Renowned for their flexibility and reliability, these valves are integral to enhancing the efficiency of complex hydraulic operations. Understanding their functionality provides insights into their widespread use in industries such as manufacturing, mining, and agriculture. Given their significance, it is essential to explore their components, technological advancements over the years, and their impact on the hydraulic ecosystem.

Rexroth modular valves are hydraulic components designed to regulate the flow and pressure within a system. These valves are distinguished by their modular nature, allowing for easy integration and adaptability to system requirements. The design ensures that they can be easily connected with other components, making them highly versatile and efficient. Their modularity facilitates a wide variety of configurations, enabling engineers to tailor solutions that best fit specific applications and operational demands. The integration of sophisticated technology ensures that these valves operate seamlessly in conjunction with other hydraulic elements.

Utilizing Rexroth modular valves brings several advantages:

These valves are utilized across a myriad of industries:

| Brand | Modularity | Application Flexibility | Performance Reliability | Cost Efficiency |

|---|---|---|---|---|

| Rexroth | High | Wide range of applications | Excellent | Optimal |

| Brand A | Medium | Limited applications | Good | Moderate |

| Brand B | Low | Niche applications | Average | High |

The comparison above illustrates Rexroth's dominant position in the hydraulic valve market, driven by its high modularity and flexibility for diverse applications. Understanding the differences among brands allows businesses to make informed decisions regarding their hydraulic systems, ensuring they choose the option that aligns with their operational goals and requirements.

Some of the standout features include:

Rexroth modular valves significantly contribute to the overall performance of hydraulic systems. By ensuring precise control of flow and pressure, they optimize the efficiency of machinery, reduce energy usage, and enhance operational safety. This, in turn, leads to extended equipment life and lower maintenance costs. The ability to manage not just flow but also provide feedback on performance metrics ensures that users can pinpoint inefficiencies and act proactively to mitigate them.

When integrated into a hydraulic system, the performance metrics can include everything from flow rates and pressure thresholds to maintenance alerts, allowing for a data-driven approach to equipment management. This informs operators about when to perform maintenance checks or component replacements, thereby avoiding unforeseen system failures and costly repairs.

Q: Can Rexroth modular valves be customized for specific applications?

A: Yes, their modular nature allows them to be customized to meet specific system needs. From different sizes, strengths, and configurations, users can select the exact components necessary for their hydraulic circuits.

Q: What maintenance is required for these valves?

A: Routine inspections and timely replacement of seals are recommended to maintain optimal performance. Regular checks ensure that any potential issues, such as leaks or wear, are identified before they lead to significant operational disruptions.

Q: Are there compatibility issues with other hydraulic components?

A: Rexroth modular valves are designed for compatibility, but it's crucial to ensure system-wide compatibility before integration. Understanding the specifications and tolerances of existing equipment will ensure seamless integration.

Q: How do these valves improve energy efficiency?

A: By optimizing the flow and reducing unnecessary pressure fluctuations, they contribute to lower energy consumption. Efficient hydraulic control translates into less power used for operations, thus minimizing the overall operational cost.

Q: What additional benefits do smart Rexroth modular valves offer?

A: Smart Rexroth modular valves provide real-time monitoring, enabling predictive maintenance and data insights that aid in operational decision-making. These modern features ensure that operators can assess the performance trends over time, leading to more informed future purchases and upgrades.

The field of hydraulics is continually evolving, and Rexroth has been at the forefront of many technological innovations in modular valve design. Over the past few years, various advancements have improved not only functionality but also the user experience associated with these components.

One of the most significant advancements is the incorporation of IoT (Internet of Things) technology, which enables real-time data transmission and analytics. This integration allows equipment operators to access performance data remotely, facilitating real-time adjustments and predictive maintenance strategies, and ultimately enhancing operational efficiency. Moreover, advancements in materials science have led to the production of more durable and lightweight valve components, improving installation ease and longevity.

Furthermore, The advancement of software controllers that can integrate with modular valves allows for programmable automation, providing operators with the ability to program complex workflows and machine interactions into their hydraulic systems. This adaptability not only increases functionality but also provides customization options for varied applications across sectors.

As industries continue to integrate more automation and smart technologies, the demand for modular valves is expected to grow. Future designs may incorporate even more advanced technology, such as artificial intelligence, which could potentially redefine how operators interact with and control hydraulic systems. The trend towards sustainability in manufacturing and industrial operations is also shaping the evolution of modular valves, with increasing emphasis on energy efficiency and environmentally friendly practices.

Moreover, as sectors such as renewable energy and electric vehicles continue to expand, the role of hydraulic systems and consequently modular valves will become central in these new technologies. Industry leaders are already researching how modular designs can contribute to greener practices and more energy-efficient operations.

Rexroth modular valves have established themselves as essential components in the modern hydraulic landscape due to their flexibility, reliability, and efficiency. Their ability to seamlessly integrate into various systems while delivering precision and durability makes them a preferred choice across multiple industries. Embracing Rexroth’s innovative technology not only ensures operational excellence but also paves the way for future advancements in hydraulic engineering. The continuous evolution of these modular valves, driven by technological innovations and the focus on efficiency, highlights their future importance in maintaining industrial competitiveness in a rapidly changing environment.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!