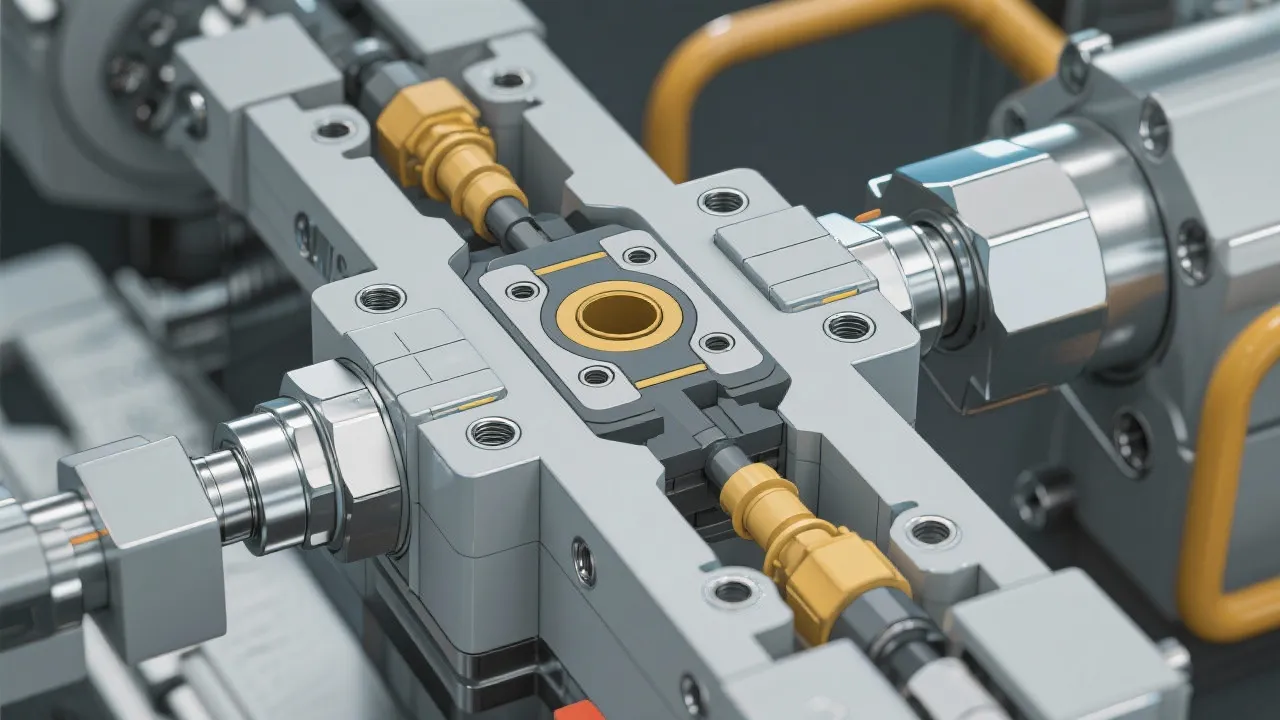

Hydraulic cartridge valves are crucial components within fluid control systems, utilized across various industries for their efficiency and reliability. These valves are designed to control the flow and direction of hydraulic fluids, offering benefits such as compact design and enhanced system performance. Understanding their role and applications helps optimize mechanical operations.

Hydraulic cartridge valves play a pivotal role in modern hydraulic systems. They are designed to manage the flow and direction of hydraulic fluids essential for powering machinery and equipment. These valves are highly coveted for their crucial operational efficiency, compactness, and precision in controlling hydraulic systems across varied industrial applications. This guide explores their importance and functionality, helping industry professionals make informed decisions.

In industrial settings, particularly in manufacturing and heavy machinery, hydraulic cartridge valves are indispensable. These components are adept at controlling flow rates, managing pressure, and directing fluid movement, which directly enhances the performance and reliability of hydraulic systems. They are highly favored in industries such as construction, agriculture, and automotive due to their ability to withstand harsh environments and offer precise fluid control.

For instance, in the construction industry, hydraulic cartridge valves facilitate the efficient operation of heavy equipment such as excavators and bulldozers. These machines rely on hydraulic pressure to perform functions like lifting heavy loads, digging trenches, or moving materials. The precise control provided by hydraulic cartridge valves allows these machines to operate smoothly and efficiently, significantly increasing productivity on job sites.

In agriculture, hydraulic systems powered by cartridge valves are commonly used in tractors and planting equipment. The ability to control various functions, such as adjusting the position of plows or planters, is critical for precision farming. The use of these valves ensures that the equipment operates at optimal performance, resulting in better yield and reduced operational costs.

Moreover, the automotive industry utilizes hydraulic cartridge valves in various systems, from vehicle braking to transmission. High-performance vehicles particularly benefit from these valves, as they provide a high level of control and responsiveness that translates to improved safety and driving experience.

The operational principle of hydraulic cartridge valves hinges on controlling fluid flow through internal passages. When actuated, these valves either allow or restrict fluid flow, based on the requirements of the system. This function is automated and can be finely tuned, offering mechanical advantage and improving the system's response time to changing conditions. Their design includes a housing with internal components that ensure fluid regulation is both efficient and reliable.

Typically, hydraulic cartridge valves operate using a spool or ball mechanism. When a spool inside the valve is moved by hydraulic pressure or an external actuator, it changes the flow path and directs the fluid accordingly. This valve movement is highly precise and can be controlled electronically in modern applications. For example, in a hydraulic lift system, altering the position of the spool can raise or lower the lift platform safely and efficiently.

Moreover, many hydraulic cartridge valves integrate features such as pressure relief and back-pressure compensation, enhancing their functionality. These added features enable the valve to maintain optimal operation by regulating pressure extremes, which can otherwise lead to system failure or component wear. The choice of materials used in the manufacturing of these valves, often high-strength steel or specialized alloys, ensures durability and effectiveness in demanding environments.

The adoption of hydraulic cartridge valves comes with several advantages. Firstly, their compact design makes them ideal for systems with limited space, facilitating ease of integration and maintenance. This compactness is particularly beneficial in applications where space is at a premium, such as in mobile machinery or small manufacturing systems. Additionally, their modular structure allows for interchangeability and reduces the need for extensive piping and connections, leading to fewer potential leakage points.

Secondly, they contribute to energy conservation within hydraulic systems, as their precise operation prevents fluid wastage. By minimizing leaks and ensuring that fluid flows only when needed, these valves significantly enhance system efficiency, resulting in lower energy consumption and operational costs.

Reliability and operational longevity are other notable benefits. High-quality hydraulic cartridge valves are designed to withstand various environmental conditions, including extreme temperatures and exposure to contaminants, without compromising performance. This leads to decreased downtime and maintenance costs, presenting a cost-effective solution for industries that rely heavily on hydraulic technology.

Furthermore, modernization of hydraulic cartridge valves is leading to enhanced functionalities, like the incorporation of digital feedback and remote operation capabilities. As industries move towards smart factories and automation, hydraulic cartridge valves are evolving to meet these demands, offering greater control and data analytics to optimize performance even further.

| Type | Description |

|---|---|

| Check Valves | Allow fluid flow in one direction while preventing backflow. They are essential for ensuring that hydraulic pressure is maintained in a system, particularly in applications such as hydraulic pumps where backflow can cause damage or inefficiencies. |

| Pressure Control Valves | Regulate and maintain specific pressure levels within the hydraulic system. These valves are crucial for safety and performance, as they prevent system overloads and ensure that machinery operates within its designed pressure limits. |

| Flow Control Valves | Control the rate of fluid flow in the hydraulic system, ensuring optimal performance. By adjusting the flow rate, these valves enable precise movements in hydraulic circuits, essential for tasks requiring a specific speed or force. |

| Directional Control Valves | Direct fluid flow paths within the system, crucial for proper machinery operation. The ability to change flow direction allows for complex machinery operations, such as in hydraulic cranes that need to lift and move heavy loads in various directions. |

In addition to these common types, there are also combination valves that integrate multiple functionalities into a single cartridge. These multi-function cartridges can simplify hydraulic system design and improve efficiency by reducing the number of individual components required.

Moreover, specialized cartridge valves exist for niche applications, such as modulating valves for systems that require variable flow control based on external parameters or proportional valves designed for high-precision movement in robotics and automation systems.

Industry experts highlight the growing need for efficient hydraulic systems, prompting advancements in cartridge valve technology. Innovations aim at enhancing versatility and response time while maintaining robust performance under extreme conditions. With increasing automation across industries, the integration of smart technologies in these valves is becoming more prevalent, facilitating remote monitoring and real-time adjustments in hydraulic systems.

This shift towards smart hydraulic systems entails the adoption of Internet of Things (IoT) technology in hydraulic components. By embedding sensors and communication modules within cartridge valves, manufacturers can provide real-time data on fluid pressure, flow rates, and valve status. This data allows operators to make informed decisions regarding system performance and maintenance needs, minimizing downtime and maximizing productivity.

Additionally, the development of advanced materials and manufacturing techniques has led to lighter and more durable cartridge valves. Innovations such as 3D printing and advanced composites are being explored to produce valves that meet strict performance criteria while reducing weight and manufacturing costs. These developments are particularly significant in the aerospace and automotive industries, where weight savings can lead to improved fuel efficiency and performance.

As industries increasingly focus on sustainability and reducing their environmental impact, hydraulic systems powered by cartridge valves are also evolving to support greener practices. Energy-efficient designs, coupled with the integration of renewable energy sources, are making hydraulic systems more socially responsible. Hydraulic cartridge valves designed for biocompatible fluids or those that have low environmental impacts are gaining traction in sectors like agriculture, where chemical contamination of the soil and water needs to be minimized.

In conclusion, hydraulic cartridge valves are critical components in today’s hydraulic systems, serving various industries by enhancing operational efficiency, precision, and reliability. As technology continues to advance, the development of smarter, more efficient cartridge valves promises to revolutionize hydraulic applications further, making it an exciting area of growth and innovation. Understanding their functionality, applications, and benefits can empower industry professionals to optimize their hydraulic systems, reduce operational costs, and contribute to a more sustainable future.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!