Rexroth Modular Valves play a pivotal role in hydraulic systems, offering a modular design that enhances flexibility and efficiency. These valves allow precise control over fluid dynamics, contributing significantly to the reliable operation of machinery across industries. This article delves into their applications, benefits, and technical aspects, providing industry insights and answering common queries.

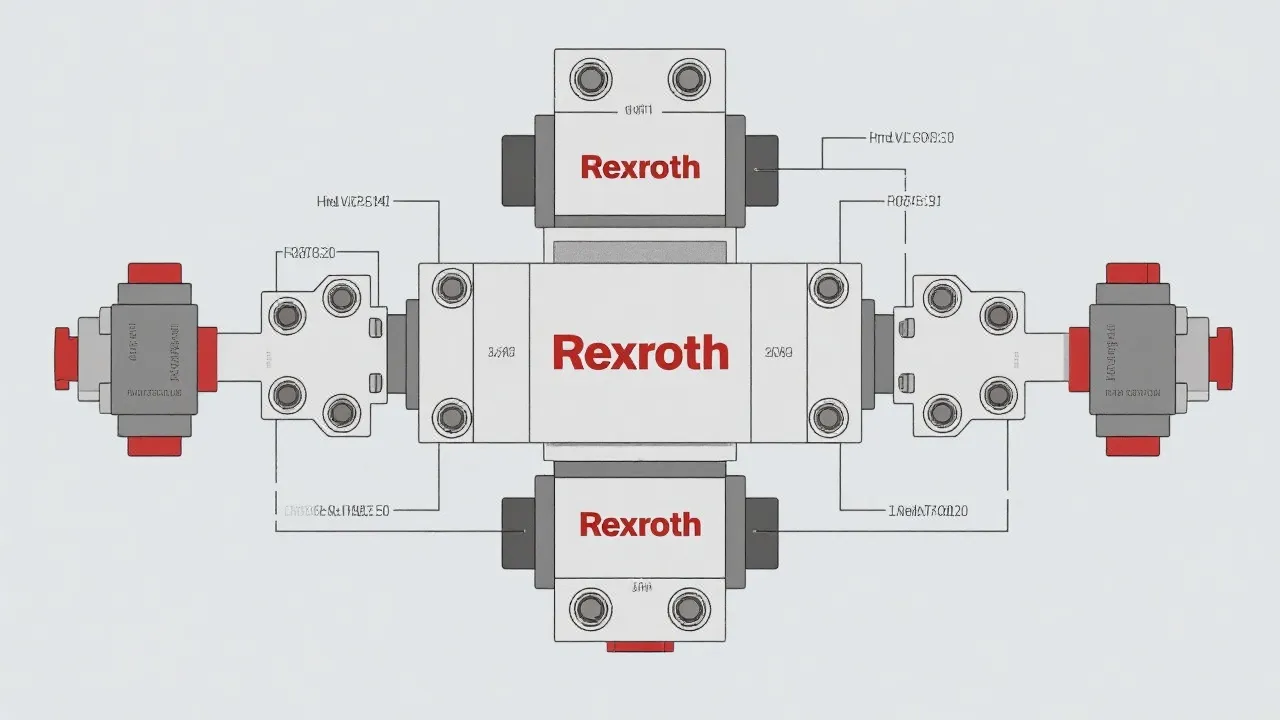

Rexroth Modular Valves are an integral component in hydraulic systems, widely recognized for their versatility and efficiency. These valves are designed to offer a modular approach to handling hydraulic systems, allowing for enhanced control over flow, pressure, and other critical parameters. Their role in ensuring the optimal functioning of machinery across various sectors cannot be overstated. Whether it's in manufacturing, automotive, or construction, the application of Rexroth Modular Valves is indispensable.

The importance of hydraulics in modern machinery cannot be understated. Hydraulic systems are essential for transmitting power through pressurized fluids, and valves play a crucial role in controlling these systems. Rexroth Modular Valves allow operators to maintain precise control, decreasing the risk of system failures and improving overall performance.

This modular concept gives users the ability to customize their hydraulic configuration according to specific application needs, making Rexroth a preferred choice among engineers and maintenance professionals alike. The ability to adapt and change configurations without significant hardware changes significantly reduces both time and cost for maintenance teams.

The design of Rexroth Modular Valves focuses on modularity, providing users with the flexibility to configure hydraulics per their specific requirements. Key features include:

Due to their adaptable design, Rexroth Modular Valves are employed across various industries:

| Benefit | Description |

|---|---|

| Scalability | Valves can be adapted to varying system demands without full system redesigns. This feature is critical for businesses that need to scale operations quickly or adapt to technological advancements. |

| Cost-Effective Maintenance | The modular design reduces the need for complex installations, thereby lowering maintenance costs. Easier maintenance translates to less downtime and operational costs overall. |

| Reduced Downtime | Quick and easy replacements mean less time is lost during servicing. The ability to swap out components without extensive effort allows businesses to maintain productivity levels. |

| Compliance | Designed to meet international standards, ensuring broad applicability and reliability. This compliance is crucial in sectors where regulatory standards are tightly controlled. |

| Improved Safety | The reliability of flow control reduces the risk of hydraulic failures, contributing to a safer operational environment. With strict adherence to safety standards, these valves play a significant role in protecting both workers and machinery. |

| Environmental Responsibility | Enhanced efficiency and reduced leakage align with environmental sustainability goals, making Rexroth Modular Valves a responsible choice for advancements in hydraulic technology. |

From an engineering perspective, the appeal of Rexroth Modular Valves lies in their technical prowess. They offer seamless connectivity with other hydraulic components, ensuring a harmonious flow path for fluids. Advanced computational fluid dynamics and material science have enhanced their design, focusing particularly on minimal leakage and resistance, thereby ensuring high-efficiency rates are maintained.

Moreover, the versatility of hydraulic configurations allows businesses to innovate and adapt their systems to the latest technological advances. For example, the introduction of the latest digital controls paired with hydraulic actuators maximizes the potential of modular valves for smart machinery implementations.

Rexroth Modular Valves are built with safety features that provide automatic shutoff capabilities in case of system failures. This preventive feature is vital for maintaining system integrity and preventing catastrophic failures that could lead to operational downtime or safety hazards.

Furthermore, the integration of sensory technology in modern modular valves allows for real-time monitoring and control. This connectivity enables operators to make data-driven decisions that can enhance overall system performance and reduce inefficiencies.

What makes Rexroth Modular Valves unique?

Their unique modular design allows easy customization and integration into existing systems, providing superior control over hydraulic processes. This unique feature also aligns with the trend toward Industry 4.0, where modular designs facilitate rapid deployment and iteration of machinery.

How do such valves improve system efficiency?

By minimizing fluid leaks and optimizing flow, these valves enhance the overall efficiency of hydraulic systems. Their ability to maintain consistent pressure translates to lower power consumption and less wastage in fluid resources.

Are Rexroth Modular Valves suitable for all types of hydraulic systems?

While they are versatile, their suitability depends on the specific requirements and configurations of the system in question. It's essential to consult engineering specifications and compatibility checks when integrating these valves into new or existing systems.

Where can I purchase Rexroth Modular Valves?

These are available through certified suppliers globally. It is crucial to purchase from reputable sources to ensure authenticity and support. Additionally, many suppliers offer technical support to help with the integration and maintenance of these sophisticated components.

How do I determine the right specifications for my application?

Selecting the right Rexroth Modular Valve requires detailed knowledge of your hydraulic system’s requirements. Understanding parameters such as pressure ratings, flow rates, and system dynamics is vital. Consulting with a hydraulic expert or supplier will help in making the correct choices.

In conclusion, Rexroth Modular Valves represent an evolution in hydraulic system management. Their modular nature not only provides a high degree of adaptability but also ensures that systems can be run more efficiently with minimal downtime. As industries increasingly lean towards automation and the need for efficiency grows, such technological innovations become indispensable. The enhanced safety features, cost-effectiveness, and environmental responsibility demonstrated by these valves solidify their role as vital components in modern engineering. Always ensure to source these components from trusted suppliers to maintain the integrity and performance of your systems.

As the demand for efficient hydraulics continues to rise globally, investing in Rexroth Modular Valves presents an opportunity to streamline operations and achieve greater productivity across various sectors. Their applications are set to expand further as technology advances, making them a forward-looking component of any hydraulic system.

Looking ahead, the role of Rexroth Modular Valves in industrial innovation will continue to be pivotal. As companies push for more automation and smarter systems, these valves will be at the forefront of providing the necessary reliability and functionality needed to drive growth and operational excellence in an ever-evolving environment.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!