The Rexroth Tc08 remains at the forefront of industrial automation, renowned for its precision and reliability. This article delves into its pivotal role in contemporary manufacturing processes, accentuating its capabilities that are transforming precision engineering. Understanding the facets of the Rexroth Tc08 helps industries enhance productivity and ensures seamless operations.

The Rexroth Tc08 has established itself as an industrial stalwart, significantly impacting automation and control systems. Known for its precision and dependability, this component aids industries in optimizing manufacturing processes and enhancing productivity. Widely utilized in various sectors, the Tc08 is celebrated for its versatility and cutting-edge technological capacity. The need for efficient automation in manufacturing environments has never been greater, and the Tc08 stands at the forefront, providing solutions that address both current and future industrial challenges.

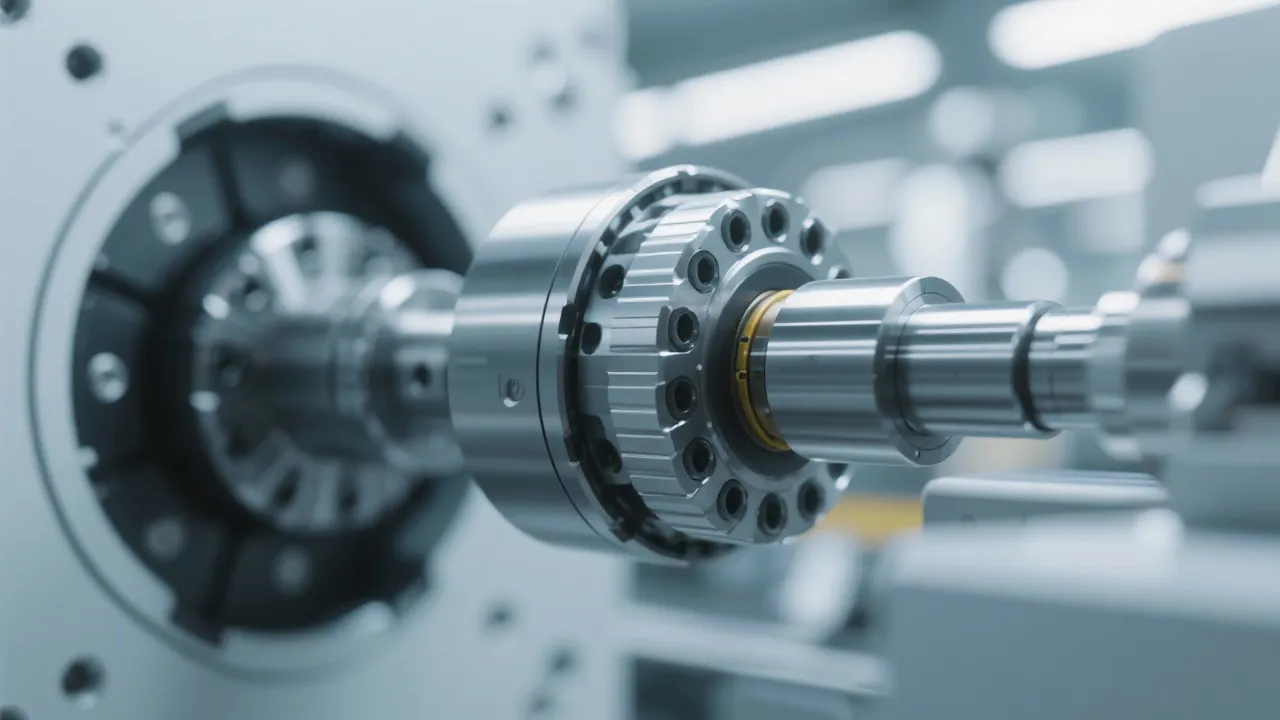

Key attributes of the Rexroth Tc08 include advanced control algorithms, a robust design for maximum durability, and ease of integration with existing systems. This component excels in precision control, allowing for meticulous manipulation of industrial processes. Its robust nature ensures it withstands demanding environments, ensuring operational consistency. Features such as real-time data processing and adaptive learning capabilities enhance its performance, making it a smart investment for businesses looking to leverage automation technology effectively.

Additionally, the Tc08 supports a variety of communication protocols, which allows seamless connectivity with other devices in a manufacturing setup. This flexibility not only simplifies integration but also facilitates a more cohesive operational ecosystem, where information flows freely between different components, enabling smarter decision-making and faster reaction times. Moreover, the Tc08’s energy-efficient design contributes to reduced operational costs, making it an environmentally sustainable choice for manufacturers.

Industries vary in their application of the Rexroth Tc08, from automotive to packaging. In the automotive sector, it contributes to precise component assembly, ensuring that every piece fits perfectly to meet stringent quality standards. In the realm of packaging, it guarantees consistency and speed in production, optimizing the flow of goods through automated lines. The adaptability of the Tc08 means that it can be tailored to specific industrial needs, regardless of the complexity involved.

In the electronics industry, the Tc08 plays a crucial role in the assembly of components on printed circuit boards (PCBs), where precision is of utmost importance. The ability to control minute movements with extreme accuracy not only improves production rates but also reduces defects, thereby enhancing overall quality assurance. Furthermore, in industries such as pharmaceuticals, where regulatory compliance and precision are critical, the Rexroth Tc08 facilitates the exact dosages and assembly processes needed for sensitive products.

A key trend emerging across industries is the increasing use of robotics. The Rexroth Tc08 acts as the backbone for these robotic applications, providing the necessary control logic and interfacing capabilities to enable seamless operation. In warehouse management systems, it helps automate the sorting and distribution processes, contributing to greater logistical efficiency. As the demand for flexible manufacturing and Just-In-Time (JIT) production grows, the Tc08 ensures manufacturers can adapt swiftly to changing market dynamics, making it an indispensable tool in the modern industry landscape.

According to industry experts, the Rexroth Tc08 represents a significant step forward in automation technology. Its blend of precision and efficiency is unmatched, providing manufacturers with the tools needed for high-quality output. Experts recommend its inclusion in systems where precision and reliability are paramount, particularly as manufacturing environments increasingly gravitate towards automation. The ability of the Tc08 to self-adjust and learn from its environment is positioning it as a leader in Industry 4.0 applications, where connected devices and data analytics play crucial roles.

The effectiveness of the Rexroth Tc08 is often highlighted in case studies demonstrating how companies have successfully integrated it into their systems. For instance, a leading automotive manufacturer reported a 30% reduction in assembly time after implementing the Tc08's advanced automation solutions. The integration allowed for real-time monitoring and adjustment of assembly line speeds, ultimately leading to significant savings in both time and resources. Similarly, a major electronics firm utilized the Tc08 to streamline their PCB assembly process, resulting in a marked decrease in error rates and improved overall efficiency. These findings underscore the Tc08's reputation as a leading choice for modern manufacturing challenges.

Moreover, market analysts predict that as industries continue to invest in automation and smart manufacturing practices, the demand for solutions like the Rexroth Tc08 will grow exponentially. This trend indicates a broader industry shift, where the integration of smart technologies is seen as essential for maintaining competitiveness. As more firms strive for operational excellence, the adoption of the Tc08 could become a defining factor in ensuring sustained growth and innovation.

As industries evolve towards more automated systems, the Rexroth Tc08 will continue to be a cornerstone. Its ability to deliver high-performance results makes it a preferred choice for manufacturers aiming for operational excellence. As technology advances, the Tc08's role is anticipated to expand, further cementing its place in industrial innovation. With the growing emphasis on sustainability, the energy-efficient design of the Tc08 aligns well with global efforts to reduce the carbon footprint of manufacturing processes.

Additionally, the continued advancement of artificial intelligence and machine learning technologies will further enhance the capabilities of the Tc08. As it becomes integrated with more intelligent systems, the potential for predictive maintenance, dynamic optimization of production lines, and real-time analytics will revolutionize how manufacturers approach quality control and efficiency.

The future landscape of manufacturing is one marked by increased complexity and greater operational demands. The Rexroth Tc08 stands ready to meet these challenges, not just as a tool for automation, but as a pivotal component in a broader strategy towards smart manufacturing and industrial IoT. As businesses look to the future, those who harness the power of solutions like the Tc08 will undoubtedly lead the charge towards enhanced productivity and competitive advantage in an ever-evolving marketplace.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!