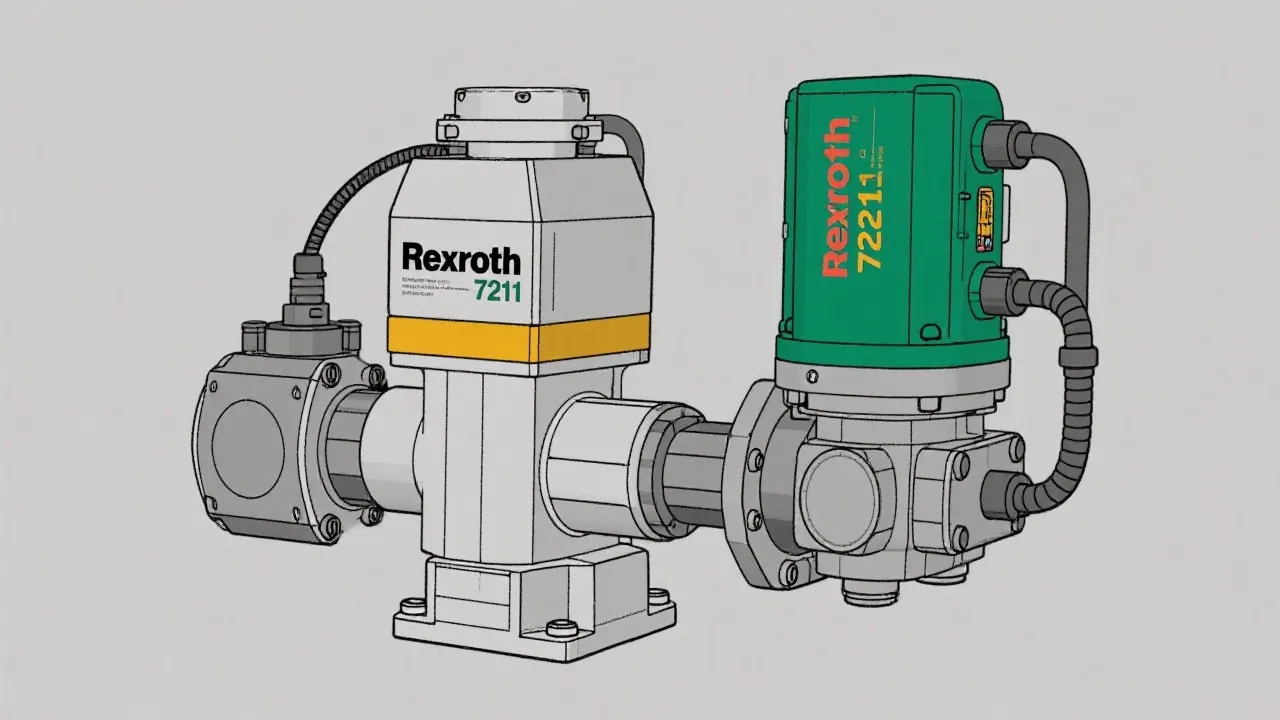

The Rexroth 7291 stands as an innovative product in the field of hydraulic solutions, offering advanced features that cater to diverse industrial applications. Manufactured by Bosch Rexroth, a leading name in drive and control technologies, this equipment is part of a suite that emphasizes efficiency, precision, and reliability for modern engineering demands.

In the arena of hydraulic solutions, Rexroth 7291 has emerged as a significant innovation, underscoring the prowess of contemporary engineering. A product of Bosch Rexroth, a company renowned for its high-quality products in drive and control technologies, the Rexroth 7291 is designed to meet the increasing demands for efficiency and precision in industrial settings. This article delves into the intricacies, applications, and benefits of integrating the Rexroth 7291 into modern engineering practices.

Rexroth 7291 combines cutting-edge technology with robust engineering principles to deliver performance that stands out in various industrial applications. Its design not only enhances operational efficiency but also contributes to sustainability by minimizing energy consumption. The equipment is engineered to deliver optimal control, supporting both basic and complex hydraulic systems. Among its key features is a sophisticated closed-loop hydraulic control which allows for the precise modulation of flow, pressure, and speed, thereby responding dynamically to operational demands.

Primarily, the Rexroth 7291 finds its application across industries such as manufacturing, construction, and automation. In the manufacturing sector, it aids in powering machinery that demands precise control and rapid response. Construction industries benefit from its capacity to handle heavy loads, making construction equipment more reliable. Meanwhile, in automation technology, Rexroth 7291 facilitates seamless integration with automated systems, enhancing productivity and accuracy. Beyond these sectors, this product also proves essential in mobile machinery, where space constraints and mobility add further complexity to hydraulic solutions. Furthermore, sectors such as agriculture increasingly adopt the Rexroth 7291 for applications in tractors and harvesters where hydraulic efficiency is paramount for operation in fields.

Key features include high durability, adaptability in extreme conditions, and an intuitive interface that simplifies operation. The sophistication in Rexroth 7291's design ensures it can withstand substantial operational pressures without compromising performance. Additionally, its flexible configuration options enable it to be tailored for specific needs, making it versatile for an array of functions. The built-in diagnostic tools facilitate predictive maintenance, allowing operators to preemptively address potential issues before they escalate into costly downtimes. This proactive approach minimizes disruption across manufacturing lines and enhances overall productivity. Furthermore, the Rexroth 7291 includes safety features that are compliant with international standards, ensuring safe operation in diverse working environments while prioritizing operator health and safety.

Rexroth 7291 is available through numerous suppliers globally, with Bosch Rexroth’s extensive dealer network ensuring widespread distribution. This accessibility is crucial for industries looking to integrate advanced hydraulic solutions in their operations. Prospective buyers are encouraged to engage with certified suppliers to receive genuine products and optimal after-sales support. In addition, Bosch Rexroth often provides an array of resources, including catalogs, technical documentation, and detailed service manuals that assist buyers in understanding the full capabilities of the Rexroth 7291. This thorough support extends to online platforms, where users can find video tutorials, webinars, and forums that foster community learning and problem-solving.

| Feature | Rexroth 7291 | Competitor A | Competitor B |

|---|---|---|---|

| Efficiency | High | Moderate | High |

| Sustainability | Environmentally friendly | Standard | Eco-friendly |

| Durability | Robust | Reliable | Robust |

| Support & Service | Excellent | Average | Good |

| Integration Capability | Seamless | Limited | Moderate |

Implementing Rexroth 7291 within an industrial setup requires careful planning to harness its full capabilities. This process often involves aligning existing infrastructure with the new system, training personnel, and undergoing a phase of testing to ensure all parameters are met. Designing a successful integration strategy involves a multi-phased approach starting from initial assessments to determine compatibility with current systems. Engineering teams must evaluate hydraulic circuits, identify operational loads, and align them with the performance metrics that the Rexroth 7291 offers. Post-installation, a systematic testing phase should follow, where operators assess the system’s response under varied loads to ensure it meets performance expectations.

Fortunately, Bosch Rexroth provides ample resources and support to facilitate this transition for its users. The company often offers training workshops that provide hands-on experience with the Rexroth 7291, making operators proficient in utilizing its full range of capabilities. Additionally, Bosch Rexroth's commitment to customer support extends beyond the sale of products; feedback loops are established where users can report their experiences and suggest improvements which are then addressed in future product iterations.

To fully appreciate the Rexroth 7291's capabilities, it’s essential to explore real-world case studies that showcase its efficiency and reliability in action. One notable example is in the automotive manufacturing sector, where a leading automobile manufacturer faced challenges in optimizing the performance of its assembly lines. By integrating the Rexroth 7291, they were able to achieve significant enhancements in hydraulic control systems, leading to increased productivity and reduced waste. The result was a 20% improvement in productivity metrics and a remarkable 30% reduction in energy consumption, showcasing the impact advanced hydraulic solutions can have on operational efficiency.

In another instance, a construction company utilized the Rexroth 7291 in their hydraulic excavators. The integration allowed for more precise movements and better handling of heavy materials. Feedback garnered from operators indicated a notable improvement in their ability to execute complex tasks with minimal downtime. The hydraulic system’s resilience in harsh weather conditions further validated the product's adaptability, supporting operations that were previously hindered by equipment failure in extreme conditions.

The seamless integration of Rexroth 7291 into industrial applications exemplifies how modern engineering can drive efficiency and innovation. By leveraging its advanced features, industries can enhance productivity while adhering to rigorous sustainability standards, making it a worthwhile investment for future-forward operations. As manufacturers strive to strike a balance between productivity and environmental responsibility, innovations like Rexroth 7291 serve as integral solutions in crafting a modern, efficient, and sustainable industrial landscape. The ongoing advancements in hydraulic technology and the supportive ecosystem around Rexroth 7291 ensure that businesses not only keep pace with the demands of today's market but are also prepared for the evolving challenges of tomorrow.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!