Rexroth Modular Valves play a pivotal role in hydraulic systems, known for their efficiency and adaptability. These valves are integral to the seamless operation of various industrial applications. Here, we delve into the specifics of Rexroth Modular Valves, exploring their functionalities, advantages, and the impact they have on industrial processes by providing a deeper understanding of their mechanisms and benefits.

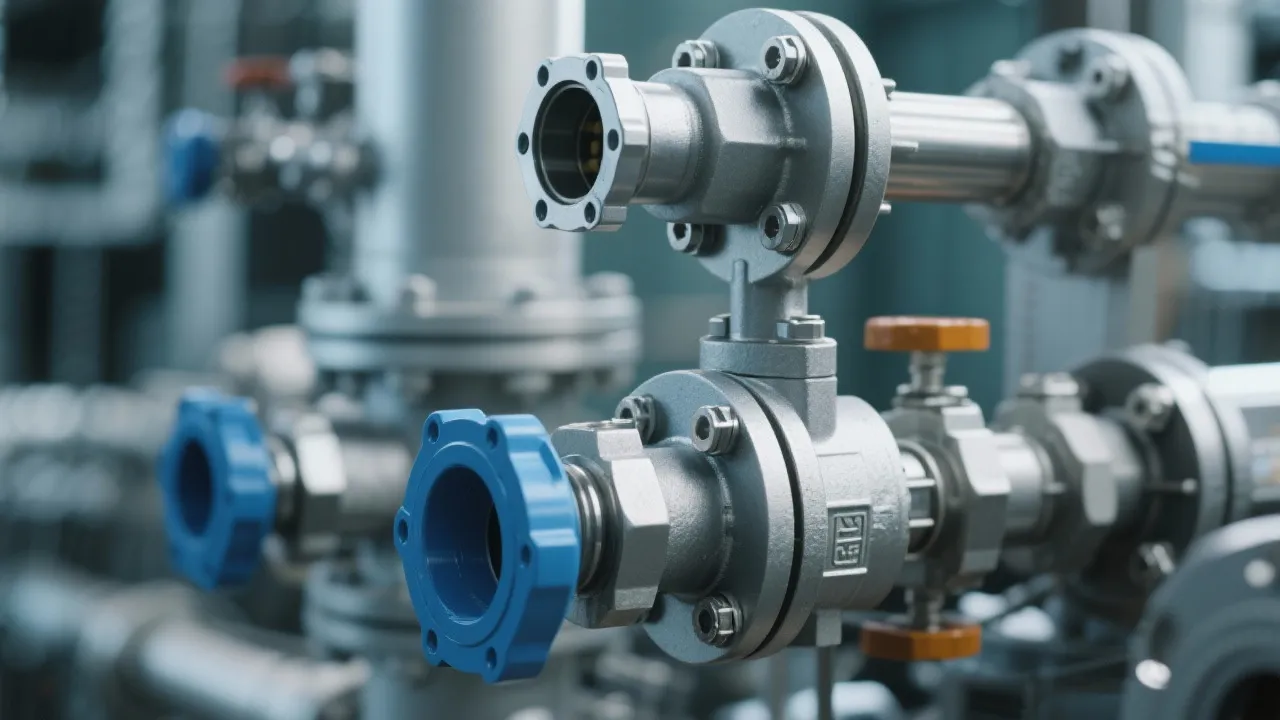

Rexroth Modular Valves are a staple in the field of hydraulic systems, celebrated for their superior operational efficiency and versatility. As key components in controlling fluid flow, pressure, and direction, these valves ensure that machinery and industrial processes function reliably and efficiently. Bosch Rexroth, a leading manufacturer in the hydraulics industry, designs these valves with rigorous standards to meet a variety of industrial needs.

At the core of Rexroth Modular Valves is their ability to manage fluids in complex hydraulic systems. These valves are engineered to provide optimal control over different aspects of hydraulic circuits, such as flow rate, direction, and pressure. They are modular, meaning that each valve consists of interchangeable components that can be customized to meet specific system requirements. This modularity enhances flexibility, allowing for easy adjustments and replacements without the need for significant system overhauls.

The design of these valves also reflects advanced engineering principles that allow for comprehensive functionality. Each modular valve encompasses various components, including control blocks, pressure relief valves, and directional control valves, which can be tailored to specific applications. This adaptability is particularly beneficial for businesses that require unique hydraulic solutions due to the specific nature of their operations.

Moreover, the construction of Rexroth Modular Valves utilizes high-quality materials that are resistant to wear and corrosion, ensuring consistent performance over time. Each valve undergoes rigorous testing and quality assurance measures to ensure reliability in demanding environments. The attention to detail in design and manufacturing underscores Bosch Rexroth’s commitment to providing top-tier hydraulic components that meet international standards.

The primary advantage of Rexroth Modular Valves is their adaptability. They are designed to integrate seamlessly into a wide array of hydraulic systems, significantly enhancing system performance. Some key benefits include:

In addition to these core advantages, Rexroth Modular Valves also make a significant contribution to overall system efficiency, enhancing the sustainability of industrial operations. With proper configuration and usage, these valves lead to reduced energy losses and improved overall system performance.

Due to their versatility, Rexroth Modular Valves find applications in diverse industries such as manufacturing, automotive, and energy. They are essential in machinery used for material handling, industrial automation, and process control systems. In each application, these valves contribute to enhancing efficiency, productivity, and safety. For instance, in automotive manufacturing, Rexroth Modular Valves are employed in assembly line machinery, allowing for precise control over robotic arms and conveyor systems.

In the manufacturing sector, these valves facilitate seamless operation in CNC machines, presses, and other heavy machinery, enhancing throughput and reliability. Rexroth Modular Valves also play a critical role in renewable energy systems, such as wind and hydraulic energy generation, where their adaptability can lead to optimized performance in fluctuating environments.

The energy sector utilizes Rexroth Modular Valves in hydraulic systems for oil and gas extraction, refining, and transportation. In each of these applications, the need for precise control over fluid dynamics is critical for safety and efficiency. The valves ensure that machinery operates within the specified parameters, thus minimizing the risk of failures that could have catastrophic consequences.

Moreover, the agricultural industry benefits from Rexroth Modular Valves through their integration into modern farming equipment, allowing for efficient operation of hydraulic systems in tractors, combine harvesters, and irrigation systems. Their ability to regulate intense hydraulic pressure in such machinery translates into improved yield and reduced fuel consumption, promoting sustainability in agricultural practices.

| Feature | Rexroth Modular Valves |

|---|---|

| Material Quality | High-grade materials for durability and resilience, minimizing wear over time. |

| Customization | Modular components for easy customization and scaled solutions according to industry needs. |

| Maintenance | Simplified due to modular construction; individual components are easily replaceable. |

| Control Precision | High level of precision for efficient flow control, contributing to cost-saving and enhanced productivity. |

| Integration Capability | Designed for seamless integration into a variety of hydraulic systems across multiple industries. |

| Operational Efficiency | Optimizes energy consumption and enhances process outcomes through reliable performance. |

Industry experts recognize the critical role Rexroth Modular Valves play in modern hydraulics. Their ability to seamlessly integrate into existing systems makes them a preferred choice for engineers and designers looking to improve system performance. The versatility and modularity allow for tailored solutions, which is essential in markets that are increasingly demanding in terms of efficiency and adaptability.

Experts note that, as industries shift toward more sustainable practices, the use of efficient components like Rexroth Modular Valves is paramount. These valves not only reduce energy consumption but also help manufacturers meet stringent environmental regulations. By optimizing machinery performance and reducing waste, these valves align with global efforts to enhance sustainability in industrial operations.

Moreover, the ongoing advancements in technology further support the evolution of Rexroth Modular Valves. With the introduction of digital monitoring systems and smart technology, these valves are beginning to incorporate Internet of Things (IoT) capabilities, allowing for real-time data monitoring and predictive maintenance. This technological integration is anticipated to enhance functionality, making Rexroth Modular Valves even more crucial in modern manufacturing and process control environments.

The primary benefits include enhanced system reliability, flexibility, ease of maintenance, and improved precision in control, all of which contribute to overall system efficiency. Additionally, the durability of these valves allows them to withstand the rigors of industrial applications, which can lead to significant cost savings over time.

By improving the efficiency of hydraulic systems, these valves help in reducing energy consumption and minimizing resource wastage, thus supporting sustainable industrial practices. They contribute to lower operational costs while simultaneously helping businesses meet environmental standards—that dual focus on economic and environmental impact is increasingly important in today’s market.

While they are highly versatile, it's essential to consult with manufacturers or specialists to ensure suitability for specific industrial applications and requirements. Different industries have unique pressures, temperatures, and flow requirements, and while Rexroth Modular Valves can meet many of these, some specific applications might require tailored solutions or adaptations.

Regular inspections, timely replacement of worn-out components, and following manufacturer guidelines for servicing can help maintain optimal performance and extend the lifespan of these valves. It is also advisable to keep records of maintenance activities and monitor the operation of valves to identify any irregularities early on.

Implementing measures such as routine hydraulic fluid checks, cleanliness protocols, and ensuring that the operating environment is free from contaminants are also important aspects of valve maintenance. Additionally, proper training for personnel operating and maintaining these systems can lead to better handling and care of hydraulic components.

As technology evolves, so do the features and capabilities of Rexroth Modular Valves. Incorporating cutting-edge technology means that these valves not only meet current industrial standards but also pave the way for future advancements. Some advanced features worth noting include:

These advanced features ensure that Rexroth Modular Valves aren't just foundational components in hydraulic systems; they are smart components driving the next generation of industrial automation and efficiency.

The future of Rexroth Modular Valves looks promising as industries increasingly adopt automation and smarter technologies. As more manufacturers strive for efficiency and sustainability, solutions that incorporate advanced hydraulics like those offered by Rexroth will become essential. The demand for energy-efficient systems, combined with the emergence of smart factories, points toward a rising role for modular valves in integrated hydraulic solutions.

As industries look to enhance their production processes, integrating Rexroth Modular Valves with modern technologies such as Artificial Intelligence (AI) and machine learning will facilitate predictive maintenance. This can greatly minimize downtime and enable real-time adjustments to hydraulic systems based on operational data, thus increasing reliability.

Moreover, the implications of Industry 4.0 and the trend of digitization in manufacturing will likely fast-track the development of sophisticated hydraulic systems. Companies that leverage the capabilities of Rexroth Modular Valves alongside other smart technologies stand to gain a significant advantage in competitive markets.

Furthermore, ongoing research and innovation from Bosch Rexroth promise to yield new features and improvements, ensuring that their modular valves remain at the forefront of hydraulic technology. Emphasizing high performance and sustainability, developments may include biomimetic designs or synthetic materials that reduce environmental impact.

In conclusion, the future landscape of hydraulic systems looks to be closely intertwined with the evolution of Rexroth Modular Valves, making them vital to the next wave of industrial transformation. By combining flexibility, precision, and evolving technology, they are poised to tackle the complexities and demands of future industrial applications.

Rexroth Modular Valves represent a significant advancement in hydraulic technology. Their design emphasizes adaptability, precision, and durability, making them indispensable in a variety of industrial settings. By understanding the intricacies of these valves, industries can make informed decisions to enhance system performance and operational efficiency. Their versatility not only positions them as essential components in traditional hydraulic systems but also as critical players in the evolving landscape of modern industrial processes.

Ultimately, the investment in Rexroth Modular Valves is not just about improving existing systems but about preparing for a future where efficiency, sustainability, and technology go hand in hand. Stakeholders in various sectors can leverage the power of these valves to drive innovation, meet regulatory demands, and fulfill corporate sustainability objectives, thereby crafting a path toward a more efficient and environmentally responsible industrial era.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!