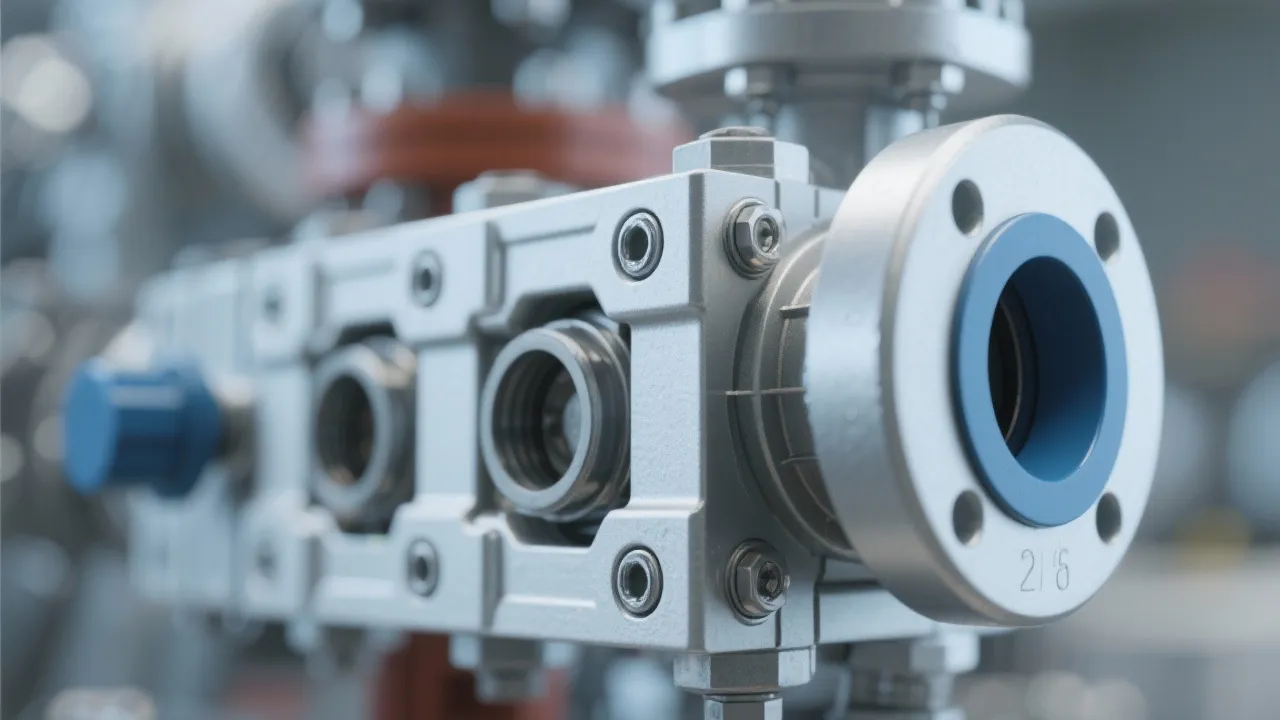

The article delves into the intricacies of Rexroth Modular Valves, highlighting their importance in fluid control systems within various industrial applications. Rexroth, a global leader in hydraulic technology, offers highly adaptable valve systems designed to enhance efficiency and performance across sectors. This guide provides an expert analysis of these components, explaining their configurations, benefits, and applications.

The industrial world continually seeks enhanced efficiency and adaptability, primarily influenced by innovations in fluid control systems like Rexroth Modular Valves. As a key player in hydraulic technology, Rexroth offers a range of modular valves designed to cater to versatile applications, from simple machinery operation to complex automation processes. With these valves, industries ensure precise control of fluid flow, achieving desired performance in various operational environments.

The ability of these modular valves to be customized plays a pivotal role in optimizing performance and operational efficiency. By enabling tailored specifications, Rexroth Modular Valves not only support current operational needs but also allow versatility for future enhancements. This is essential in today's fast-paced industrial settings, which often necessitate adjustments to machinery and processes to maintain competitiveness.

Modular valves, such as those offered by Rexroth, are distinguished by their flexible design structure. Each module in a Rexroth system can be customized and configured to cater to specific applications. This modularity ensures that valve assemblies can be adapted or expanded according to the operational needs without replacing entire systems. Such adaptability is crucial in industries where process requirements evolve rapidly or where equipment cost management is paramount.

Moreover, modular systems enable easier maintenance and troubleshooting. If a single module fails or requires servicing, it can be replaced without the need to disrupt the entire hydraulic circuit or machinery operation. This not only saves time but also minimizes downtime—a critical factor in maintaining productivity levels.

The ease of assembly and reconfiguration provided by modular valves also translates into lower operational risks. Operators can swiftly alter setups to match changing production requirements without compromising reliability. This contributes to greater overall system resilience, an increasingly vital trait for manufacturing processes that respond dynamically to market demands.

Rexroth Modular Valves are characterized by their robust construction and precise engineering. Key features include:

Additionally, Rexroth invests heavily in the modern design and simulation of new valve types, staying ahead of competitors by continuously refining features that align with user feedback and technological advancements. The integration of smart technologies in newer valve models allows for better monitoring and data analysis, pushing the boundaries of functionality even further.

The versatility of Rexroth Modular Valves allows them to be used in a wide range of applications, such as:

The adaptability of Rexroth Modular Valves to various environments is reinforced by extensive testing and compliance with international quality standards, ensuring industries can rely on these products even in the most challenging settings.

As industries strive for technical advancements, comparing different modular valve systems becomes essential. Let’s evaluate some parameters:

| Parameter | Rexroth Modular Valves | Competitor A | Competitor B |

|---|---|---|---|

| Configuration Flexibility | Highly customizable, allowing configurations for specific tasks. | Moderately flexible with predefined options. | Limited options restrict customization possibilities. |

| Durability | High, designed for long-term performance under stress. | Medium, susceptible to wear under extreme conditions. | High, but with lower customization capability. |

| Cost-effectiveness | Competitive pricing for the robust features offered. | Expensive, often not justifiable for some applications. | Moderate, balancing features with affordability. |

| Industry Applications | Broad range, suitable for diverse sectors. | Specific niches, limiting overall market reach. | Moderately broad, but lacks robustness in specialized applications. |

This comparison provides valuable insights for businesses considering upgrading or implementing modular valve systems. Understanding these differentiating factors can guide investment decisions, ensuring that the chosen system aligns with operational goals and financial capabilities.

In the rapidly evolving industrial sector, the importance of reliable and versatile fluid control cannot be overstated, and Rexroth Modular Valves exemplify the height of engineering excellence in this field. Whether for manufacturing, construction, or agricultural applications, these valves provide a robust solution to enhancing operational efficiency. By understanding their capabilities and configurations, businesses can optimize their systems, ensuring they meet current and future demands.

Furthermore, investing in high-quality modular valves comes with the added advantage of future-proofing operations. As industries move towards more automated and integrated solutions—including IoT-capable machinery—the adaptability of Rexroth Modular Valves allows for ongoing upgrades without the need for significant overhauls. This positions businesses to remain competitive amid continual technological advancements.

As industries witnesses a shift toward sustainability, the energy-efficient features of Rexroth Modular Valves support environmental initiatives while simultaneously reducing operational costs. Adoption of such innovative technologies ensures not only economic viability but also contributes to the broader goal of fostering a more sustainable future in industrial operations.

Ultimately, understanding Rexroth Modular Valves' intricate design, technical advantages, and application versatility equips operators and decision-makers with the knowledge necessary to enhance their fluid control systems strategically. Embracing these advancements can lead to significant improvements in productivity, safety, and sustainability across various sectors.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!