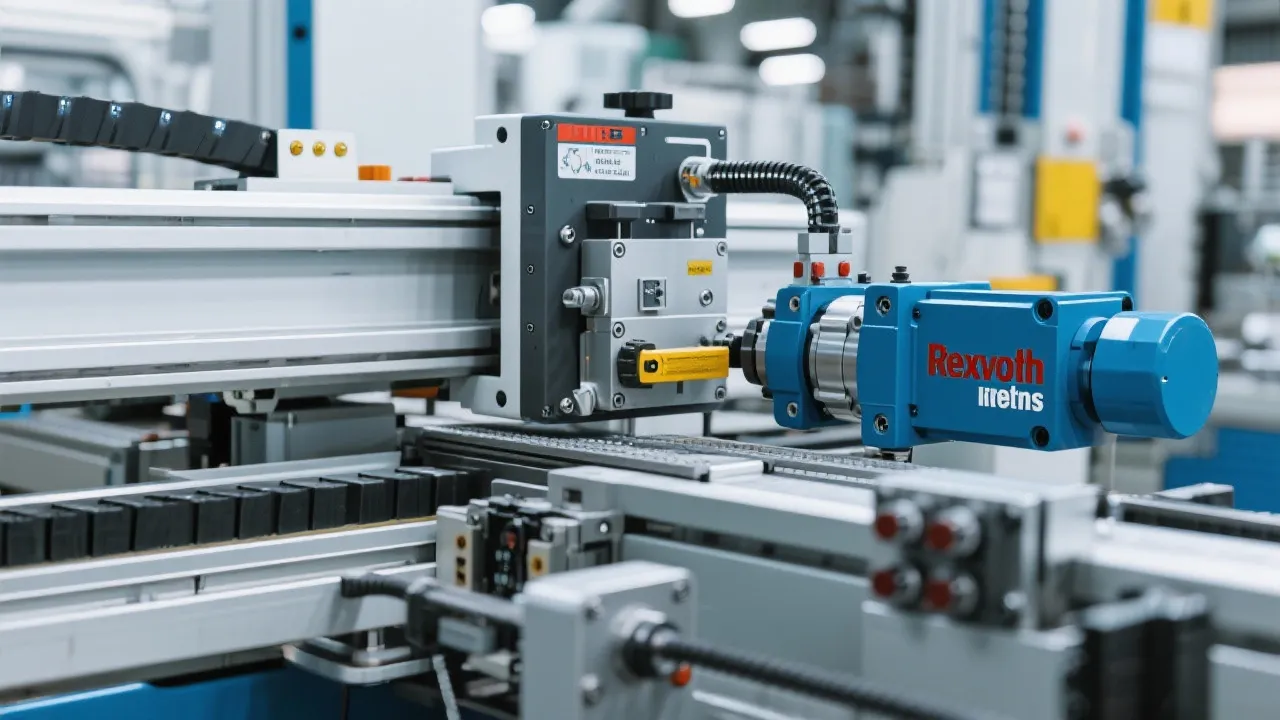

This article provides a detailed exploration of Kbps Rexroth systems, focusing on their application and significance in modern industrial settings. Known for their efficiency and reliability, Kbps Rexroth components have become integral to manufacturing processes worldwide. Emphasizing their technological advancements and robust performance, this guide delves into their critical role, offering insights from industry experts and answering frequently asked questions.

Kbps Rexroth is a pivotal name in the realm of industrial machinery, offering a spectrum of components essential for efficient manufacturing operations. Their reputation for innovation and quality makes them a preferred choice for industries seeking reliable and high-performance solutions. The components provided by Kbps Rexroth range from control systems to actuators, creating a comprehensive suite of products that address myriad operational needs across multiple sectors.

In the rapidly evolving industrial landscape, the adaptability of machinery components is crucial. Kbps Rexroth systems stand out with their versatile applications, seamlessly integrating into various manufacturing processes. These systems are engineered to enhance productivity by ensuring precision and minimizing downtime, thereby elevating operational efficiency. Whether it is in automotive manufacturing, food and beverage processing, or pharmaceutical production, Kbps Rexroth systems are designed with flexibility in mind to meet the specific demands of diverse industries.

Kbps Rexroth has consistently pioneered technological advancements that set benchmarks in the industry. Their systems integrate seamlessly into hydraulic, electric, and mechanical applications, providing solutions that cater to diverse industrial needs. The modular nature of these components allows for easy customization and scaling, ensuring that industries can tailor solutions according to their specific requirements. For example, the integration of IoT technology into their machinery has facilitated remote monitoring and predictive maintenance, enhancing operational efficiency. Additionally, advancements in automation technology have enabled manufacturers to achieve greater consistency and quality in their outputs.

Some specific applications of Kbps Rexroth systems include:

The hallmark of Kbps Rexroth systems lies in their reliability and efficiency. Designed to withstand rigorous industrial environments, these components offer longevity and robust performance. This reliability contributes to consistent operations, reducing the need for frequent maintenance and repairs, which in turn, optimizes costs. The quality of materials and sophisticated engineering processes that go into manufacturing Kbps Rexroth components ensure they perform exceptionally well under pressure. Industries have reported significant reductions in downtime and maintenance costs after switching to Kbps Rexroth systems.

Moreover, the advanced design of Kbps Rexroth products often includes features like self-diagnostics, which can alert operators to potential issues before they lead to significant problems. This proactive approach to maintenance ensures that companies can schedule repairs during non-production hours, minimizing disruption to operations. Additionally, energy efficiency is a critical focus area; many Kbps Rexroth systems are designed to consume less power while maintaining high performance, thus contributing to an organization’s sustainability goals.

The global reach of Kbps Rexroth is a testament to their effectiveness. Industries around the world have adopted these systems as a cornerstone of their manufacturing processes. Kbps Rexroth not only provides the tools for automated systems but also contributes to the strategic planning and implementation of such systems, facilitating a more holistic approach to efficiency in manufacturing. An expert from a leading industrial consultancy notes, “The integration of Kbps Rexroth systems is crucial for industries aiming to achieve seamless operation and scalability.” This has become increasingly important as manufacturers look to expand their operations both locally and globally.

The rise of Industry 4.0 has led to a heightened demand for intelligent manufacturing solutions. Kbps Rexroth’s ability to innovate and adapt to these changes positions it as a leader in the industry, helping businesses transition to smart factories. Furthermore, global trends such as sustainability and digital transformation have driven many organizations to reevaluate their operational strategies. Kbps Rexroth is particularly adept at providing solutions that align with these trends, offering technologies that not only boost productivity but also enhance ecological efficiency.

Implementing Kbps Rexroth systems requires a systematic approach to maximize their benefits. Here is a step-by-step guide to ensure effective integration:

Throughout these steps, ongoing communication among team members, engineers, and Kbps Rexroth representatives is essential. Regular check-ins can uncover potential issues early, allowing for swift adjustments. In addition, it is beneficial to establish clear parameters for success, such as reduced production time or decreased error rates, to measure the system's impact post-implementation.

| Feature | Description |

|---|---|

| Modular Design | Offers customizable solutions tailored to exact industrial needs, allowing manufacturers to scale operations efficiently. |

| High Precision | Ensures accuracy and efficiency in operations, particularly important in industries like pharmaceuticals and aerospace where precision is paramount. |

| Durability | Engineered for longevity, reducing maintenance requirements and ensuring that maintenance costs are kept low. |

| Energy Efficiency | Products designed to consume less energy while maintaining peak performance, assisting in meeting corporate sustainability goals. |

| Integrated Technology | Seamless integration with IoT and automation technologies, facilitating advanced monitoring and control capabilities. |

Primarily manufacturing and industrial sectors utilize these systems for enhanced efficiency in production processes. Key fields include automotive, electronics, food and beverage, and life sciences, where high standards of precision and reliability are necessary.

Yes, the modular nature of these systems allows for customization to meet specific industrial requirements. Depending on process needs, organizations can select from various configurations and components to build an optimal system.

By following a structured implementation process, industries can reduce downtime and increase productivity, capitalizing on the fast and precise capabilities of Kbps Rexroth systems. A meticulous implementation plan leads to streamlined processes, improved product output quality, and lower operational costs.

Kbps Rexroth provides ongoing support that includes troubleshooting, maintenance training, and access to updated technology. Continuous monitoring and evaluation services are also typically available to ensure that systems remain effective and are upgraded as necessary to keep pace with technological advancements.

Integration is designed to be as seamless as possible. However, the specific ease of integration depends on existing machinery and processes. Kbps Rexroth’s team often assesses current setups to provide tailored solutions that incorporate existing systems into new installations effectively.

The true potential of Kbps Rexroth systems can be illustrated through various real-world applications where significant changes and improvements were realized. Here we present a few notable case studies that exemplify the capabilities and advantages of these systems across different industries.

A leading automotive manufacturer faced challenges with their assembly line due to outdated machinery, leading to bottlenecks, high energy consumption, and increased operational costs. Upon integrating Kbps Rexroth systems, they implemented electric linear actuators and new hydraulic controls that resulted in a 30% increase in line efficiency. The modular design of the systems allowed for phased implementation without large-scale disruptions. As a result, this manufacturer not only reduced costs but also improved product output quality, demonstrating the direct impact of these advanced technologies.

A regional food processing company struggled with maintaining hygiene standards amidst high-speed production demands. The integration of Kbps Rexroth’s automated handling systems provided a dual benefit: enhanced operational efficiency and compliance with stringent industry regulations. Sensors and smart technology were installed to monitor temperatures and flow rates in real time. This proactive approach allowed the company to address potential food safety issues before they could arise. Ultimately, they noted a significant reduction in downtime and an increase in production capacity by 25%, affirming the systems’ impact on both operational quality and safety.

A robotics company utilized Kbps Rexroth technology to enhance the precision of their robotic arms used in electronics manufacturing. By incorporating Kbps Rexroth’s high-precision motion control systems, they were able to improve the accuracy of assembly tasks, which is crucial in electronics design and manufacturing where mere millimeter deviations could lead to failures in product performance. The result was enhanced collaboration abilities between robots and human workers, significantly elevating productivity and reducing the product defect rate by 20%.

The future of Kbps Rexroth systems is poised for exciting advancements, reflecting broader industry trends and emerging technologies. Several key areas are expected to shape their evolution:

Kbps Rexroth stands as a cornerstone in the industrial sector, driving innovations that redefine operational efficiency. By integrating these systems, industries are poised to achieve remarkable improvements in productivity and reliability. The strategic adoption of Kbps Rexroth components positions companies at the forefront of technological advancement, ensuring competitiveness in an ever-evolving market. Moreover, as global industries continue to shift toward smarter, more sustainable operations, Kbps Rexroth’s commitment to delivering cutting-edge solutions ensures they will remain a beloved choice for companies aiming to thrive in the modern landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!