This article delves into the world of Dbds Rexroth, a key player in hydraulic engineering known for its high-quality and reliable components. Offering a deep dive into their innovative solutions, particularly focusing on hydraulic valves and systems, we explore their application across industries while comparing their performance and reliability to industry standards.

Dbds Rexroth has carved a niche in the hydraulic engineering sector with its unmatched dedication to quality and innovation. Specializing in hydraulic systems, the company provides components renowned for their reliability and endurance, particularly in demanding industrial environments. Understanding the intricate workings of these components can provide valuable insights into their contributions to improving operational efficiency in various fields. The company's strategy is driven by a commitment to excellence, focusing on research and development to offer products that not only meet the current needs but are also equipped to handle future challenges in hydraulic systems.

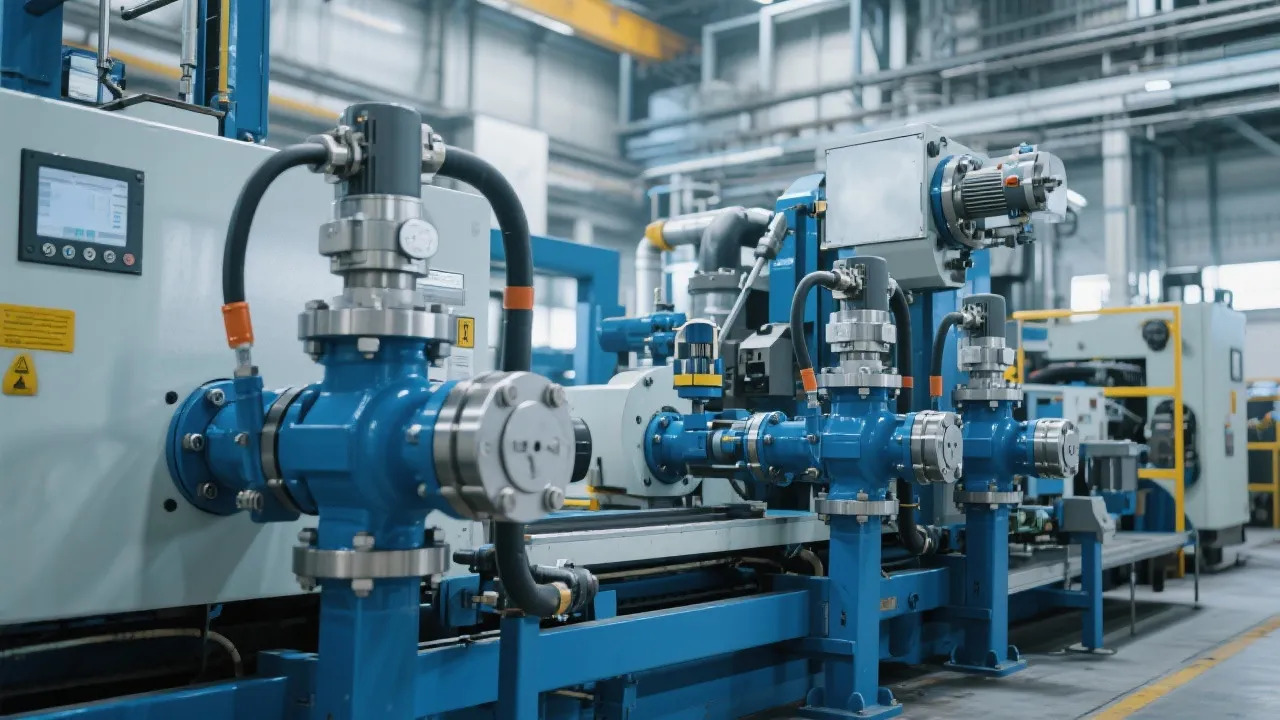

Dbds Rexroth offers a wide array of hydraulic products, including valves, pumps, and motors. These products are widely recognized for their precision and capability to withstand rigorous conditions. The hydraulic valves, a cornerstone of their product lineup, are engineered to control the flow and pressure of fluids within a hydraulic system, thereby ensuring smooth operation and preventing potential system failures. Their hydraulic pumps, essential for converting mechanical energy into hydraulic energy, are designed with cutting-edge technology that maximizes efficiency, while hydraulic motors are crafted to provide reliable rotational power for various applications.

The brand is synonymous with innovation in the field of hydraulics. Their integration of IoT and smart technologies within their hydraulic systems sets them apart, offering remote monitoring and predictive maintenance capabilities that not only enhance operational efficiency but also significantly reduce downtime and maintenance costs. This forward-thinking approach enables industries to optimize their processes, enhance productivity, and maintain consistent output. Dbds Rexroth is also pioneering advancements in energy efficiency, focusing on solutions that reduce the environmental impact of hydraulic operations.

Dbds Rexroth’s products boast a range of advanced features that provide significant benefits to users. The technology used in their hydraulic components ensures high response rates and accuracy, which is crucial in demanding applications. For instance, their valves are equipped with state-of-the-art controls that allow for fine adjustments to pressure and flow, improving overall system performance. Additionally, the materials used in their hydraulic pumps and motors have been chosen for their resilience and ability to perform under high stress and temperature, further extending the lifespan of their products.

The versatility of Dbds Rexroth products allows them to be employed across various sectors, including manufacturing, agriculture, and construction. In manufacturing, their hydraulic systems are integral in automation processes, offering the strength and precision needed in high-volume production environments. For example, in assembly lines, their hydraulic cylinders can increase speeds of operation and accuracy, which is vital for maintaining productivity.

In agriculture, their systems support efficient and sustainable farming practices by driving advanced machinery, enhancing capabilities such as planting, harvesting, and irrigation. With a growing focus on sustainable agriculture, Dbds Rexroth is contributing to systems that use less energy while increasing output. In construction, they power heavy equipment like excavators and bulldozers with reliability and precision, which are crucial for completing projects on time and within budget. The robustness of their hydraulic solutions ensures they can withstand the harsh operating conditions typical of construction sites, contributing to overall project efficiency.

| Component | Function | Applications |

|---|---|---|

| Hydraulic Valves | Control the flow and pressure within hydraulic systems to ensure optimal performance. | Used in manufacturing automation, agricultural machinery, and construction equipment. |

| Hydraulic Pumps | Convert mechanical energy into hydraulic energy to generate fluid flow. | Essential in automotive systems, mobile machinery, and industrial applications. |

| Actuators | Translate hydraulic energy into mechanical motion to perform work. | Power lifting devices, conveyor belts, and robotic systems. |

| Smart Communication Modules | Enable remote monitoring and predictive maintenance through IoT integration. | Assist in monitoring performance and health of hydraulic systems to prevent breakdowns. |

To truly understand the impact of Dbds Rexroth in various industries, examining case studies can provide deeper insights into their capabilities and contributions. One notable case involves a large automobile manufacturing facility that integrated Dbds Rexroth hydraulic systems into their assembly lines. Previously, the facility struggled with inconsistent production speeds and high downtime due to mechanical failures. By switching to Dbds Rexroth hydraulic valves and pumps, the company achieved a notable 30% increase in production efficiency. The seamless integration of IoT-enabled monitoring systems allowed for immediate detection of potential failures, preventing costly breakdowns and ensuring a smoother workflow.

Another compelling case study comes from the agricultural sector, where a cooperative of farmers adopted Dbds Rexroth hydraulic solutions for their heavy farming equipment. By utilizing hydraulic systems designed for high durability and reliability, the farmers were able to enhance their crop yields significantly. Additionally, the farming machinery equipped with Dbds Rexroth systems operated more efficiently, using less fuel and servicing costs over a relatively short agriculture cycle, which directly translated to increased profitability for the cooperative.

Feedback from clients who have implemented Dbds Rexroth hydraulic solutions consistently highlights themes of reliability, performance, and customer support. One customer, a construction project manager, stated, “Switching to Dbds Rexroth was one of the key decisions that allowed us to meet our project deadlines without compromising on quality. The hydraulic systems worked perfectly, even under the most demanding conditions.”

Another client from the manufacturing sector noted, “The precision of the Dbds Rexroth pumps and valves has been a game-changer for our assembly lines. We have seen fewer interruptions and greater output, which is crucial for our competitiveness in the market.” Such testimonials underscore the brand's reputation for delivering high-quality, efficient hydraulic solutions across various industries.

Looking ahead, Dbds Rexroth is poised to maintain its leadership position in the hydraulic systems market through ongoing innovation and adaptation to emerging industry trends. As industries continue to embrace automation and digitalization, Dbds Rexroth is dedicated to developing advanced hydraulic technologies that incorporate artificial intelligence and machine learning to drive intelligent operations. This approach will not only enhance performance but also expand the applicability of their products to new sectors that might previously rely on conventional methods.

Furthermore, as the push for sustainability intensifies, Dbds Rexroth is committed to developing solutions that align with global environmental standards. The integration of energy-saving features in their products and exploration of biodegradable materials for hydraulic applications are just a few ways the company plans to lead the way towards a greener future. The evolving landscape presents exciting opportunities for Dbds Rexroth to expand its reach and redefine hydraulic engineering standards.

Dbds Rexroth continues to lead in the hydraulic engineering field, consistently paving the way for technological advancements that enhance industrial operations. Their commitment to innovation, quality, and sustainability continues to set industry benchmarks, reinforcing their reputation as a leader in hydraulic solutions. By staying responsive to market needs and investing in future technologies, Dbds Rexroth is not just a participant in the industry but a driving force for change, ensuring that industries can operate more efficiently, sustainably, and effectively in an ever-evolving environment.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!