LVDT Proportional Valves are crucial components in modern fluid control systems due to their precision in regulating flow rates. These valves utilize Linear Variable Differential Transducers (LVDTs) to facilitate smooth and accurate operation in various industrial applications, from automotive to manufacturing. Their integration ensures enhanced performance, reliability, and stability in dynamic environments.

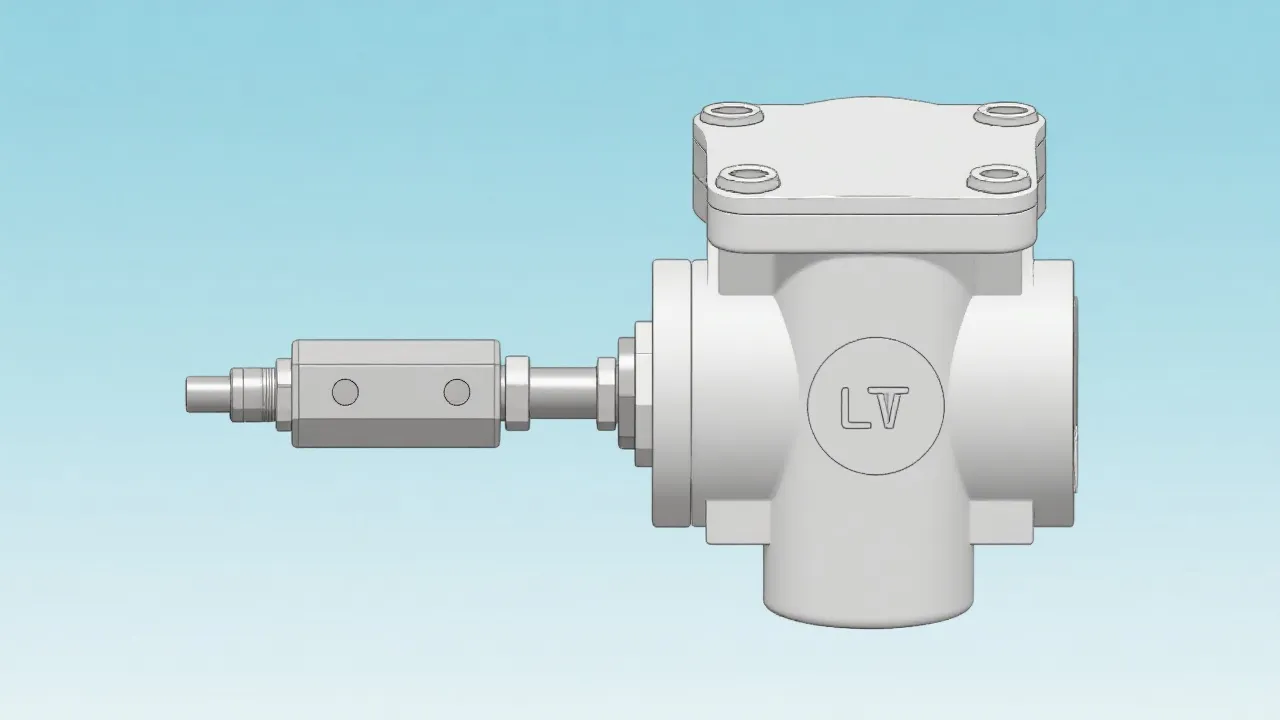

The LVDT Proportional Valve is a pivotal innovation in the field of fluid dynamics and actuation technology. At the core of its functionality lies the Linear Variable Differential Transformer (LVDT), a device renowned for its precision in measuring linear displacement. This integration enables these valves to sustain highly accurate flow control, making them indispensable across numerous industrial applications. Whether it is in automated machinery, hydraulic systems, or fuel injection mechanisms, the proficiency of an LVDT Proportional Valve in maintaining precise fluid flow is unmatched. In recent years, the demand for precise control systems in various applications has driven the evolution and advancement of this technology, making LVDT Proportional Valves even more relevant in today’s marketplace.

An LVDT Proportional Valve operates through a combination of electrical and mechanical processes. The LVDT acts as a feedback device that measures the position of the valve spool, which directly controls the amount of fluid passing through the valve. As the spool moves, the LVDT detects the displacement and sends an equivalent electrical signal to the controller. This closed-loop system is vital as it allows real-time adjustments, ensuring optimal flow rate adjustments corresponding to the system’s requirements. Furthermore, the LVDT itself consists of an oscillating transformer with a primary coil and two secondary coils configured symmetrically around it. This design leads to high sensitivity and accuracy, which are essential for modern control systems.

When the valve spool is centered, the outputs from the two secondary coils are equal, resulting in no net output voltage. However, any displacement from the center position results in a differential voltage that correlates directly to the amount of movement. This voltage is then interpreted by the control system, which prompts the valve to open or close accordingly. The effective interplay between the LVDT and the valve spool creates a mechanism not only for precise flow control but also for feedback stability crucial in many applications. Moreover, these valves can be integrated with advanced control systems such as PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems, enhancing their capabilities further.

The implementation of LVDT Proportional Valves spans several sectors. In the automotive industry, they are critical for regulating the precise fuel flow necessary for engine efficiency. This is crucial in modern engines that rely on accurate fuel-to-air ratios to optimize combustion and maintain emissions compliance. In manufacturing, these valves facilitate the smooth operation of hydraulic machinery, ensuring that processes such as molding, cutting, and shaping are performed with exact fluid pressure. In aerospace, they ensure precision in control systems where small errors can lead to significant discrepancies in flight performance, safety, and fuel efficiency.

Other industries benefiting from the advantages of LVDT proportional valves include pharmaceuticals, where controlled fluid delivery is vital in the production of medicines. In the food and beverage sector, the precise control of liquids can enhance product quality and ensure compliance with safety standards. Additionally, in renewable energy applications, such as wind and hydropower, these valves help manage the efficient flow of fluids essential in the operation of turbines and generators.

The advantages of deploying LVDT Proportional Valves are manifold. Precision and sensitivity are paramount, allowing for better control, which translates into enhanced efficiency and performance of the systems they are embedded in. Their exceptional control capabilities can lead to reduced energy consumption, lower operational costs, and extended equipment life. Moreover, they exhibit durability and reliability, reducing maintenance needs and downtime. With the capability to operate under extreme conditions, these valves provide consistent performance in both high-pressure and high-temperature environments.

Additionally, LVDT Proportional Valves have the ability to handle a wide range of fluids, including viscous liquids and gases. This versatility means they can be adapted for various applications without the need for extensive redesigns. Their compact design allows for integration into smaller machines and systems, which is particularly pertinent in today’s trend towards miniaturization in manufacturing and design.

| Feature | LVDT Proportional Valve | Standard Valve |

|---|---|---|

| Precision | High | Moderate |

| Durability | Superior | Variable |

| Cost-Effectiveness | Good savings over time | Initial low cost |

| Maintenance | Low frequency | High frequency |

| Response Time | Rapid | Slower |

| Compatibility with control systems | High | Limited |

Despite their numerous benefits, the complexity of LVDT Proportional Valves can pose certain challenges. The intricate design requires a higher initial investment compared to standard flow valves. Moreover, integrating these valves into existing systems might demand substantial modifications, which can be an additional hurdle for end-users. It is crucial to perform a comprehensive analysis of the system requirements as well as the specifications of the LVDT Proportional Valve before implementation. Careful consideration and expert consultation are recommended to ensure compatibility and efficiency.

Another important challenge involves the calibration of the LVDT system. Proper calibration is essential for optimal performance, as inaccuracies in the feedback mechanism can lead to incorrect flow control. Furthermore, users should account for environmental factors that may affect the LVDT performance, such as temperature fluctuations and electromagnetic interference. Ensuring that the installation environment is conducive to the operational requirements increases the longevity and reliability of the valve.

These valves require minimal but regular inspection to ensure they remain free from contaminants that could affect the LVDT’s performance. It is recommended to clean the valve and the surrounding area periodically and check the electrical connections for wear or corrosion. Maintaining a log of operating conditions can also help troubleshoot any unexpected performance issues.

The real-time feedback provided by the LVDT allows for immediate adjustments, optimizing the flow rate and overall system efficiency. Such responsiveness can lead to enhanced safety, as the control mechanisms can quickly adapt to changes in demand, preventing fluctuations that may cause damage or inefficiencies.

Yes, LVDT Proportional Valves are designed to perform under extreme pressure and temperature conditions, maintaining consistent output. Their robust construction is suited to hydraulic and pneumatic systems where operational pressures might exceed several thousand PSI.

Automotive, manufacturing, and aerospace industries derive significant benefits due to the precision and reliability offered by these valves. Furthermore, energy generation, marine applications, and even the chemical processing industry rely on LVDT Proportional Valves to manage fluid dynamics effectively.

The choice and implementation of LVDT Proportional Valves can greatly impact overall system efficiency by enhancing flow control, reducing energy consumption, and minimizing wastage. Utilizing these valves enables systems to operate closer to their optimal performance curve, which can lead to significant cost savings and improved productivity.

The landscape of LVDT Proportional Valves is evolving with technological advancements. One of the most notable trends is the integration of smart technology, enabling these valves to communicate with other equipment within automated systems. The implementation of the Internet of Things (IoT) allows for seamless connectivity and real-time data exchange, enhancing the monitoring and management of fluid systems.

Another emerging trend is the continued miniaturization of technology. Manufacturers are developing smaller, yet equally effective LVDT Proportional Valves aimed at applications where space is limited but precision remains critical. This trend coincides with developments in micro-electromechanical systems (MEMS), which hold the potential for revolutionizing actuation and sensing technologies.

Moreover, the use of advanced materials such as composites and high-strength alloys in valve construction is on the rise. These materials provide enhanced mechanical properties, allowing valves to withstand greater forces and environmental stressors. Future innovations may also include the development of self-calibrating systems, wherein the LVDT can adapt its calibration dynamically, thus further enhancing accuracy and reliability in varying operational conditions.

LVDT Proportional Valves stand out as a critical component in the ever-evolving landscape of industrial technology. Their precision, durability, and adaptability make them a preferred choice for industries seeking to optimize their fluid control systems. As technology advances, the integration of such sophisticated components will only become more prevalent, underscoring the importance of adopting cutting-edge solutions to meet the demands of modern engineering challenges. The continuous research and development efforts in this domain will likely unlock new possibilities that could further amplify the efficiency and efficacy of these advanced hydraulic control systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!