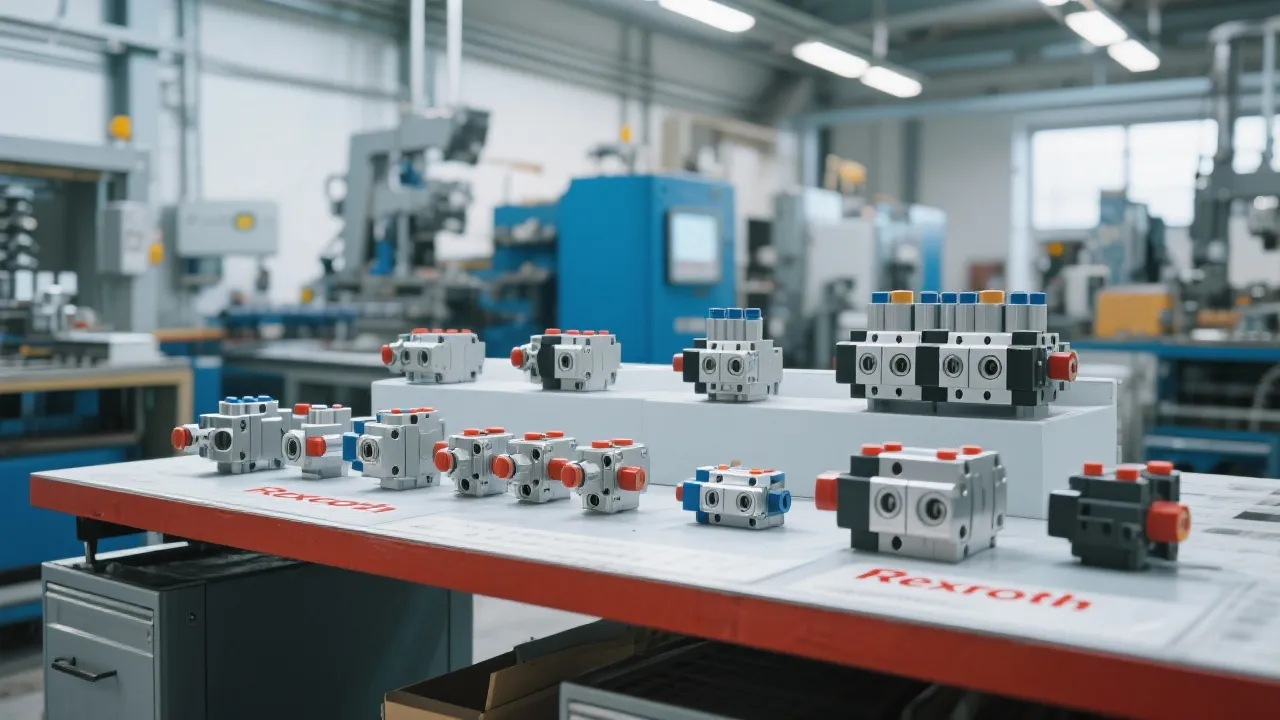

This comprehensive guide explores the intricacies of Rexroth Modular Valves, a paramount component in industrial hydraulics. These valves, renowned for their reliability and versatility, are integral to controlling hydraulic systems. By understanding their application and benefits, professionals can optimize system performance, ensuring efficiency and sustainability in various industrial sectors.

Rexroth Modular Valves are pivotal components in modern hydraulic systems. Used extensively across industries, they offer precise control over fluid flow and pressure, ensuring optimal performance and safety. Known for their modular design, these valves can be easily integrated into existing systems, offering flexibility and customization for specific industrial needs. The increasing demand for automation and efficiency in various sectors has positioned Rexroth as a leading innovator in valve technology, making their products a preferred choice for engineers and system designers alike.

The modular design of Rexroth valves contributes significantly to their popularity. It allows for easy assembly and adaptation, catering to varying industrial requirements. This design minimizes installation time and reduces maintenance costs, making them a cost-effective solution for engineers and operators. By allowing the addition of components as needed, modular valves enable manufacturers to tailor their hydraulic systems to specific tasks, enhancing both functionality and productivity. This adaptability is particularly valuable in industries where operational demands can shift rapidly, requiring quick adjustments to hydraulic systems.

Moreover, modular design facilitates upgrades and expansions. As technology advances, companies can incorporate new features and capabilities into their existing hydraulic systems without undergoing a complete overhaul. This not only saves time and resources but also minimizes operational downtime, a crucial factor in maintaining efficiency in production environments.

Rexroth Modular Valves find applications in a variety of sectors, demonstrating their versatility and reliability:

Let's delve into the technical characteristics of Rexroth Modular Valves:

| Specification | Detail |

|---|---|

| Pressure Range | Up to 350 bar, suitable for heavy-duty applications, ensuring reliability under significant loads. |

| Flow Capacity | Varies depending on the model, providing flexibility in application scenarios. This allows engineers to select a valve that meets the specific flow requirements of their systems. |

| Size | Compact design without compromising on performance, allowing integration into constrained spaces without sacrificing functionality. |

In addition to these core specifications, Rexroth also offers a variety of valve technologies, including directional control valves, pressure control valves, and flow control valves, each designed to address specific hydraulic system needs. This extensive range allows for the creation of highly specialized systems that can tackle demanding industrial tasks with precision.

Rexroth Modular Valves play a critical role in advancing industrial hydraulics. Their adaptability, robust construction, and precision make them indispensable in achieving optimized performance across sectors. As industries continue to seek efficiency and reliability, these valves will undoubtedly remain at the forefront of hydraulic innovations. The enduring reputation of Rexroth valves is a testament to their commitment to quality and precision engineering.

Looking ahead, as technology advances and demands for automation grow, Rexroth is poised to lead the way in developing even more sophisticated hydraulic solutions. With a focus on innovation, the integration of smart technologies, and sustainable practices, Rexroth aims to empower industries to achieve their operational goals while maintaining a commitment to environmental stewardship. This foresight ensures that Rexroth Modular Valves will continue to evolve, meeting the challenges of tomorrow’s industrial landscape with the same excellence they provide today.

In summary, the significance of Rexroth Modular Valves in hydraulic applications cannot be overstated. Their intricate design, reliability, and efficiency are traits that resonate through various industry applications, paving the way for enhanced productivity, safety, and environmental responsibility. Thus, they not only serve as critical components of modern hydraulic systems but also symbolize the ongoing evolution toward smarter, more efficient industrial solutions.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!