Grace Molecular Sieve is a prominent contender in the world of adsorption and separation solutions. These sieves are vital in industries such as petrochemicals, gas processing, and manufacturing due to their ability to selectively adsorb gases and liquids. The advancement in molecular sieve technology by Grace has notably contributed to greater efficiency and effectiveness in industrial applications.

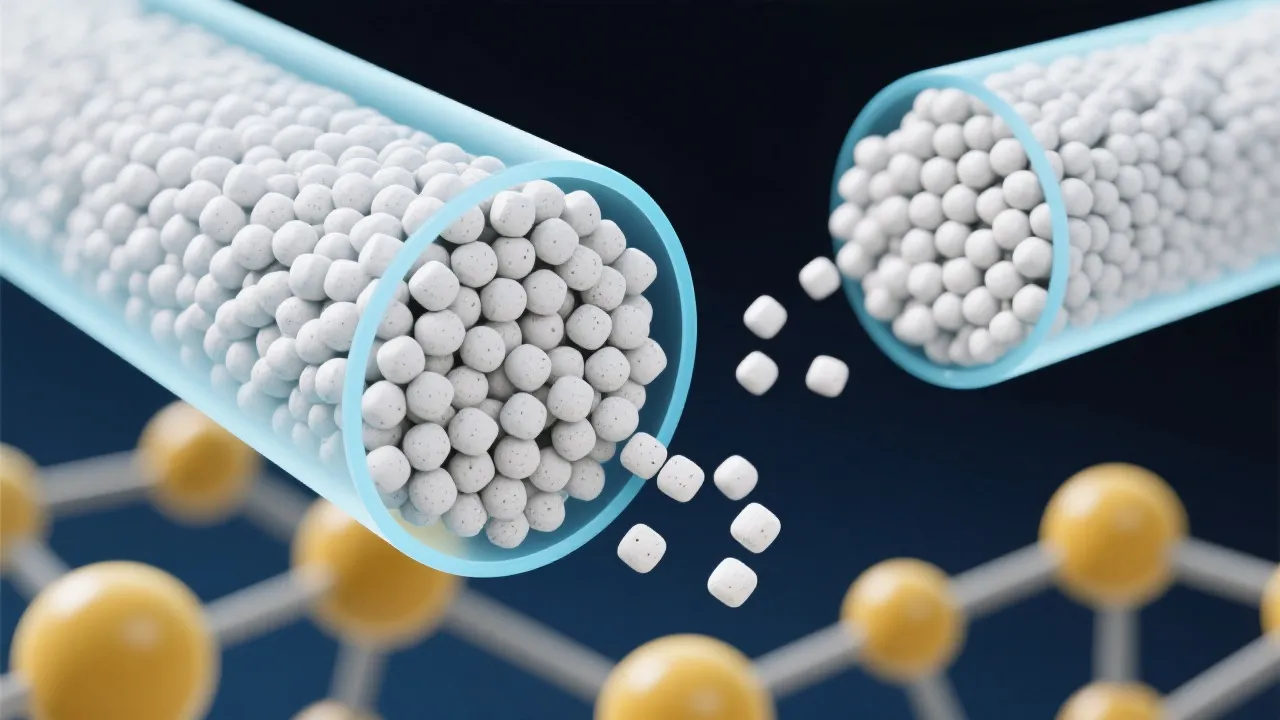

Grace Molecular Sieve is a highly engineered material used across various industries for its adsorption properties. At its core, a molecular sieve is made of crystalline aluminosilicate structures that are characterized by their uniform pore sizes, which allow them to selectively adsorb molecules based on size and shape. These structures are formed through an intricate synthesis process that not only determines the size of the pores but also the overall framework of the material, influencing its adsorption efficiency. The ability to control the pore size at the molecular level is what makes this technology exceptional in its application.

Molecular sieves are available in various forms, including pellets, beads, and powders, which can be tailored to meet the specific needs of different industrial applications. They can be classified as Type A, Type X, or Type Y, each having unique characteristics suitable for distinct adsorption tasks. The most common form, the Type A sieve, has a pore size of about 3Å, making it highly effective for the adsorption of small molecules like water. On the other hand, Type X and Y are utilized for larger molecules and have different thermal and chemical stability, expanding their usage in more challenging environments.

In the realm of industrial applications, Grace Molecular Sieve stands out due to its versatility. It plays a crucial role in petrochemical processing, where it is used to remove moisture and other impurities from gas streams. In this application, moisture removal is vital to prevent corrosion in downstream equipment and to enhance the quality of the final products. The energy sector, especially in the natural gas industry, heavily relies on the efficacy of molecular sieves to ensure that gases meet strict specifications before being transported or used in manufacturing processes.

Similarly, in air separation processes, these sieves help produce high-purity oxygen or nitrogen. By selectively adsorbing unwanted components such as argon or carbon dioxide, Grace Molecular Sieve improves the efficiency of air separation units, thus optimizing the overall production of these critical industrial gases. The innovative design of the molecular sieve ensures a low pressure drop during operation, which maximizes flow rates and further enhances productivity.

Beyond petrochemicals and air separation, molecular sieves are crucial in the pharmaceutical industry for the drying and purification of active pharmaceutical ingredients (APIs). The purity of APIs is paramount, as even trace amounts of contaminants can lead to ineffective or unsafe medications. Additionally, in the food and beverage sector, they are utilized to remove unwanted moisture and volatile organic compounds, contributing to improved shelf life and product quality. These varied applications underscore the importance of Grace Molecular Sieve across diverse sectors, reinforcing its position as a key player in enhancing product quality and operational efficiency.

The primary advantage of Grace Molecular Sieve lies in its efficiency. The precision in pore sizes ensures that only the desired molecules are absorbed, leading to fewer waste products and lower operational costs. This selectivity not only enhances efficiency but also ensures that the processes are environmentally friendly by reducing waste generation. Moreover, the durability of these sieves means they maintain their effectiveness over extended periods, reducing the need for frequent replacement and maintenance, thereby lowering long-term operational costs.

Furthermore, the thermal stability and chemical resistance of Grace Molecular Sieve allow it to perform effectively across a wide range of temperatures and environmental conditions, making it suitable for different processes without significant degradation. The ability to withstand harsh chemicals and extreme environments puts Grace Molecular Sieve ahead of many competing adsorbents, further solidifying its standing within the industry.

Another significant benefit is the ease of regeneration of the molecular sieves. Traditional adsorbents often require costly solvents or complex processes for regeneration, whereas Grace Molecular Sieve can be efficiently regenerated through simple thermal or vacuum methods. This regenerative capacity not only extends the life of the molecular sieve itself but also minimizes operational downtime, leading to increased productivity and better resource management.

Industries seeking to enhance their chemical separation and purification processes have found Grace Molecular Sieve to be a game changer. By integrating these sieves into their operations, companies can achieve more efficient use of resources, notably in reducing energy consumption and improving overall system performance. For instance, in a gas processing plant, implementing molecular sieves can lead to a significant reduction in energy costs associated with heating and cooling operations, as the removal of impurities allows for smoother chemical reactions and improved yield rates.

To effectively optimize operations, businesses must analyze their existing processes comprehensively to identify inefficiencies or bottlenecks that could be alleviated through the use of molecular sieves. Advanced modeling and simulation tools can play a crucial role in predicting how molecular sieves will interact with current systems, aiding in decision-making regarding where and how to integrate these technologies. Furthermore, consulting with experts in adsorption technology can provide personalized insights into the most effective configurations and operational parameters tailored to specific industry needs.

Another layer of optimization involves continuous monitoring and adjustment of the operational parameters. Implementing real-time analytics can assist in adjusting the flow rates, temperatures, and other conditions to maximize the efficiency and performance of the molecular sieves continuously. This iterative approach not only enhances operational performance but also allows for quicker adaptation to changing product demands or variations in feedstock compositions.

| Feature | Grace Molecular Sieve | Competitor Products |

|---|---|---|

| Adsorption Capacity | High efficiency | Varies |

| Shelf Life | Extended | Standard |

| Operational Temperature Range | Wide | Varies |

| Cost Effectiveness | Competitive | Varies by brand |

| Advanced Regeneration Capability | Efficient and quick | Complex and expensive |

| Customization Options | Highly customizable | Limited options |

Implementing Grace Molecular Sieve in industrial operations is a straightforward process but requires careful planning to maximize benefits. Initial steps include the assessment of current processes to identify areas where molecular sieves can improve efficiency and output quality. By conducting due diligence and feasibility studies, companies can better understand the expected return on investment and how the integration process will unfold.

Utilizing simulation tools and consulting with experts can further refine these integration strategies. Having a sound understanding of how molecular sieves perform under different conditions helps create the right operational framework. This might include selecting optimal flow rates and contact times based on the specific application. Additionally, collaborations with material scientists may provide insights into custom formulations of molecular sieves that can cater specifically to the unique requirements of certain processes, resulting in optimized performance and productivity.

Training personnel on best practices regarding the handling and operation of molecular sieves is absolutely critical. Providing comprehensive training sessions can ensure that staff is fully equipped to manage the sieves efficiently, which directly influences performance outcomes. This includes understanding the correct procedures for regeneration and maintenance, ensuring that the molecular sieves operate effectively over their intended lifespan.

Post-integration, it is essential to establish routine performance monitoring to evaluate the efficacy of the molecular sieves continuously. This enables businesses to detect any performance dips early and make timely interventions. These monitoring systems can often be integrated into existing operational software, streamlining data collection and analysis, and facilitating prompt decision-making.

Industries such as petrochemicals, industrial gas production, and chemical manufacturing benefit significantly from Grace Molecular Sieve. Moreover, sectors like pharmaceuticals, food and beverage, and environmental engineering also leverage these sieves for improved product quality and process efficiencies.

By increasing process efficiency and reducing resource wastage, Grace Molecular Sieve reduces operational costs and extends equipment lifespan. The low regeneration energy requirements and enhanced system performance further contribute to significant cost reductions, providing a measurable impact on a company’s bottom line.

The use of molecular sieves supports sustainable practices by minimizing by-products and energy consumption during industrial processes. These environmentally friendly characteristics make molecular sieves an integral part of industries striving for lower carbon footprints.

While Grace Molecular Sieve is generally safe to handle, it is essential to adhere to the manufacturer's guidelines regarding personal protective equipment (PPE) and handling procedures. Precautions should be taken to prevent inhalation of fine particles and exposure to high temperatures during regeneration.

The selection of the appropriate type of molecular sieve should be based on the specific size and nature of the molecules being targeted for adsorption. Consultations with suppliers or experts can provide guidance tailored to your operational needs.

Grace Molecular Sieve remains a cornerstone in the field of adsorption and separation technology, bolstering industrial processes with its exceptional performance characteristics. Its ability to enhance efficiency and effectiveness makes it an indispensable tool in various sectors, from gas processing to petrochemical refining. Moving forward, the evolution of molecular sieve technology promises even greater capabilities, reinforcing its pivotal role in modern industry.

As industries strive for better sustainability, energy efficiency, and product quality, Grace Molecular Sieve provides a practical solution that meets these increasing demands. Continuous research and development in the field of adsorption materials promise enhancements that will further widen their application spectrum, making them integral to future industrial innovations. Businesses that adopt these technological advancements position themselves at the forefront of their industry, ready to meet the challenges of tomorrow with efficiency and effectiveness in their operational capabilities.

Ultimately, the journey to optimizing industrial processes with Grace Molecular Sieve is not merely about implementing a product but undergoing a transformative change in how materials interact with each other within operational frameworks. Embracing this technology signifies a commitment to excellence, quality, and innovation in an increasingly competitive landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!