Grace Molecular Sieve significantly impacts industries like gas separation and wastewater treatment due to its superior filtration properties. This adsorbent material is renowned for its ability to selectively sort molecules based on size and polarity, making it essential in refining processes. Researchers and professionals alike value the sieve for its efficiency and effectiveness.

Molecular sieves represent a fascinating class of materials renowned for their porous structure, which gives them the unique ability to selectively absorb molecules based on size. A leader in this industry is Grace Molecular Sieve, recognized for its efficiency in various industrial applications, from air purification to gas separation. This article delves into its attributes, applications, and significance in modern technology and industry, providing a comprehensive view of how molecular sieves operate and the various sectors they influence.

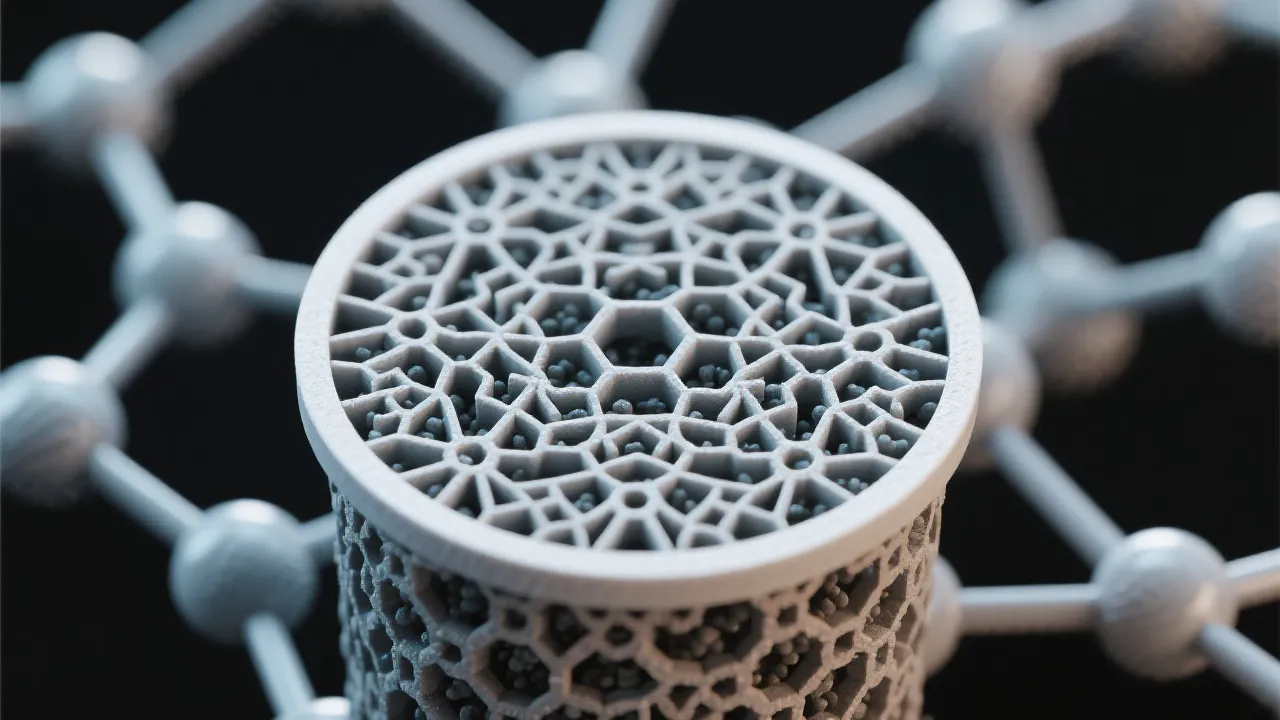

Developed and perfected by W.R. Grace & Co., Grace Molecular Sieve is a synthetic zeolite or silica-alumina compound known for its exceptional thermal and chemical stability. Unlike conventional filter systems that rely on gravity or physical barriers to sort particles, molecular sieves employ a series of micro-pores for precise separation, distinguishing molecules by dimension and polar attributes. In particular, Grace Molecular Sieve has demonstrated enhanced adsorption efficiency, making it a preferred choice in many sectors.

The synthesis of Grace Molecular Sieve involves careful control of the composition and structure of the silica-alumina framework. This level of precision ensures that the sieves can maintain consistent pore sizes, vital for their effectiveness. The process of creating these sieves typically involves hydrothermal treatment, where a gel is crystallized to yield zeolite minerals with a defined porous structure.

One of the key characteristics of Grace Molecular Sieve is its ability to be tailored for specific applications. By adjusting the synthesis parameters, manufacturers can produce sieves with specific pore dimensions — typically ranging from 3 to 10 angstroms — and surface properties. This customization allows the sieves to selectively adsorb targeted molecules while repelling those of larger size or different polarities.

The versatility of Grace Molecular Sieve spans across multiple disciplines, thanks to its tailored pore sizes and robust structure. The following sections delve deeper into specific applications, highlighting the significance of Grace Molecular Sieves in the associated fields:

Molecular sieves operate on the principle of size exclusion—or molecular recognition—where the available pore size dictates the size and type of molecules that can be adsorbed. Grace Molecular Sieve excels due to its uniform pore size distribution, which ensures high selectivity and operational efficiency in separating impurities or collecting targeted molecules.

To understand the mechanics of molecular sieves further, it is essential to consider the nature of adsorption. Adsorption occurs when molecules stick to the surface of a solid material. For effective separation processes, the sieve's surface must be highly accessible to the target molecules, which is enhanced by the large surface area to volume ratio of the sieve's microstructure. The interaction between the adsorbent and the molecules can also involve van der Waals forces, hydrogen bonding, and other intermolecular forces, depending on the chemical nature of both the sieve and the adsorbate.

Furthermore, research into the optimization of pore sizes has indicated that even slight adjustments in the pore dimension can lead to significant changes in adsorption performance. For example, smaller pores are typically more effective for absorbing smaller gas molecules like water vapor or carbon dioxide, while larger pores are necessary for larger molecules. This ongoing research helps refine the production techniques for Grace Molecular Sieves, ensuring they meet the evolving demands of various industries.

Grace Molecular Sieve provides several advantages over other filtration products:

The market for molecular sieves is expanding, driven by increasing environmental regulations and demands for cleaner, more efficient industrial processes. As industries seek to minimize their environmental footprint, the role of Grace Molecular Sieve becomes more critical. Future innovations will likely focus on optimizing pore structures and enhancing the recyclability of sieves, contributing further to sustainability initiatives.

Moreover, advancements in nanotechnology and material science might lead to the development of new forms of molecular sieves with enhanced capabilities. Research is exploring hybrid materials that combine the benefits of traditional molecular sieves with other functional materials to achieve even more significant separation efficiencies or novel applications. For instance, integrating catalytic properties could help in transforming specific molecules into more desirable products while simultaneously serving as a molecular sieve.

Both market demands for sustainable practices and technological advancements are driving new applications, especially in recycling and environmental remediation sectors. As communities and governments continue to prioritize sustainability, companies investing in molecular sieve technologies may find themselves at the forefront of eco-innovation.

| Question | Answer |

|---|---|

| How does Grace Molecular Sieve work? | It uses its uniform pore structure to selectively absorb specific molecules based on size and polarity. This allows for efficient separation processes in various industrial applications. |

| Where is the Grace Molecular Sieve commonly used? | In petrochemical, pharmaceutical, gas separation, and wastewater treatment industries, as well as in food processing and agricultural applications for maintaining product quality. |

| What makes Grace Molecular Sieve superior? | Its high adsorption capacity, longevity, and stability under extreme conditions make it effective across various applications; combined with customizability, it can be tailored for specific needs. |

| What are some environmental impacts of using molecular sieves? | Grace Molecular Sieves contribute to environmental sustainability by reducing energy consumption and waste generation through their high efficiency and long shelf life. |

| Can Grace Molecular Sieve be recycled? | Research is ongoing into the recyclability of molecular sieves. Current trends are focusing on improving material sustainability, which may lead to developments in suitable recycling methods in the future. |

Grace Molecular Sieve remains integral to many industrial sectors requiring precision separation and purification. As technology advances, so does the demand for more efficient and effective separation methods, bolstering the continued relevance and utility of Grace Molecular Sieve—an industry standard that continuously sets the bar for performance and sustainability. As researchers and manufacturers innovate, the future for molecular sieves looks promising, with potential applications expanding into untapped markets and emerging technologies. Indeed, the scientific foundation, coupled with growing environmental concerns, emphasizes the importance of Grace Molecular Sieve in shaping a sustainable industrial landscape.

In considering the deployment of Grace Molecular Sieves within various applications, it is essential to evaluate the specific operational parameters of each industry. These include factors like temperature, pressure, and the physicochemical properties of the target molecules. Understanding these elements can enhance the overall effectiveness of molecular sieves and lead to better decision-making when selecting the appropriate sieve for a given process.

Continuous improvement in production methods also plays a significant role in the overall landscape of molecular sieves. The focus on improving synthesis techniques aims to yield more consistent products with even better performance characteristics. These improvements may include new methodologies in zeolite synthesis, optimizing the crystallization processes for better pore connectivity, or even using green chemistry principles to minimize the environmental impact of production.

As industries embrace digitalization and automation, integrating molecular sieve technologies with advanced data analytics can lead to significant operational improvements. By leveraging real-time monitoring systems and predictive maintenance strategies, companies can ensure optimal conditions are maintained, thus maximizing the effectiveness of Grace Molecular Sieves and further improving productivity and environmental compliance.

Lastly, collaboration across industries, researchers, and policymakers will be crucial in driving the future advancements of molecular sieves. Such cooperation can promote information sharing and innovation while facilitating the transition of new technologies from research to practical applications. By fostering a collaborative ecosystem, companies can rapidly adapt to changing market conditions and address systemic challenges faced by various sectors involving molecular sieves.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!