Grace Molecular Sieve is a revolutionary product in adsorption technology, renowned for its efficiency in liquid and gas separation processes. As industries increasingly demand precision, this innovative solution stands out for its reliability and performance. In this guide, we explore the multifaceted benefits and applications of Grace Molecular Sieve, offering readers a holistic view of its importance across various sectors.

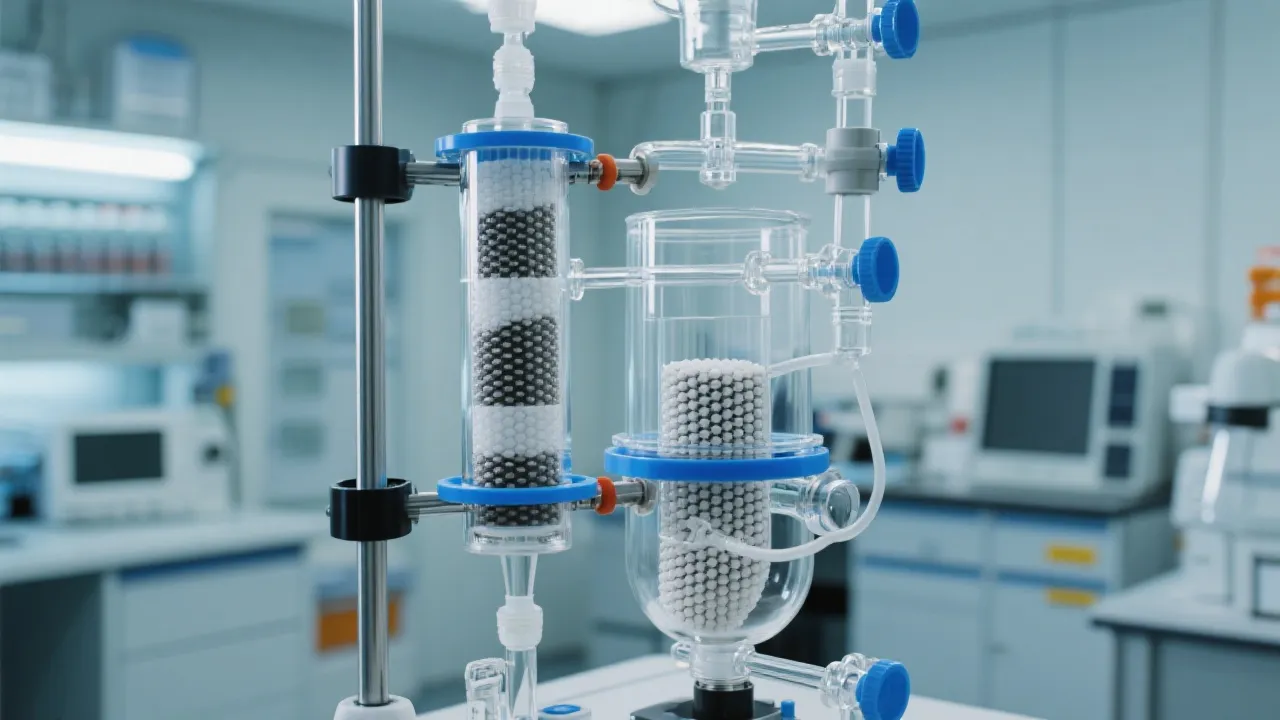

Grace Molecular Sieve is widely acknowledged in the industrial landscape for its exceptional adsorption capabilities. Primarily composed of crystalline aluminosilicates, molecular sieves function by preferentially adsorbing molecules based on size and polarity, making them indispensable across numerous applications, from dehydration to purification processes. These sieves possess a highly structured composition that allows them to selectively adsorb specific molecules from a mixture, thus enhancing the efficiency of various industrial processes.

Molecular sieves operate by exploiting the unique structure of zeolites. These structures, with their uniform, porous nature, allow only certain molecules to pass through based on size. This property is crucial in applications involving the separation of liquids and gases, demonstrating the sieve's efficiency in distinct and precise molecular separations. When different gas mixtures encounter a molecular sieve, the smaller molecules are absorbed more readily than the larger ones, thereby effectively filtering out unwanted components. This molecular size selectivity is the cornerstone of the molecular sieving process, allowing for enhanced purity of the desired products.

From an expert's perspective, the intricacies of sieving involve understanding adsorption kinetics, pore size management, and the thermodynamic properties of the sieve under variable pressures and temperatures. The adsorption process is influenced by various factors, including the nature of the adsorbate, the temperature, and the presence of competing substances. R&D teams continuously work on enhancing these factors to push the boundaries of what molecular sieves can achieve, keeping in mind the increased global demand for efficient separation technology. The development of new sieve compositions and structures that can target specific molecules with improved efficiency is ongoing, indicating a promising future for molecular sieve technology.

As industries lean toward sustainability, Grace Molecular Sieve stands out by offering eco-friendly separation solutions. By minimizing waste and optimizing resource utilization, it contributes significantly to reducing environmental footprints across multiple industries. The capability to recycle and regenerate molecular sieves multiple times further enhances their sustainability profile; this commitment to reducing chemical waste and energy consumption in separation processes is crucial in combating climate change. Additionally, as regulatory standards for emissions and waste become more stringent globally, the adoption of molecular sieves in industrial practices not only helps companies comply with these regulations but also improves their public perception and market competitiveness.

In conclusion, Grace Molecular Sieve is a cornerstone in the realm of separation technology. Its multifaceted applications across diverse industries, from pharmaceuticals to petrochemical processes, underscore its vital role in modern industrial operations. With advancements in molecular sieve technology, driven by innovation, research, and a commitment to sustainability, there is a continuous anticipation for enhanced performance capabilities. Industries can look forward to more efficient and environmentally friendly solutions to meet the challenges of the modern world, fostering a sustainable approach to industrial practices.

| Feature | Molecular Sieves | Activated Alumina |

|---|---|---|

| Common Applications | Gas separation, water removal, and the selective adsorption of specific organic compounds | Moisture control, fluoride removal, and catalytic applications. |

| Thermal Stability | High, withstanding temperatures upwards of 500°C depending on the type | Moderate, typically stable up to around 350°C before significant degradation occurs. |

| Regeneration Capability | Excellent; can be easily regenerated through heating or vacuum desorption. | Good; it can be regenerated but may require harsher conditions leading to potential loss in effectiveness over time. |

| Specificity | Highly specific; effective in separating gases and vapors based on molecular size and polarity. | Less specific; often functions as a general adsorbent with broader application range but lacks precision. |

| Application Domains | Pharmaceuticals, petrochemicals, wastewater treatment, food processing, gas purification. | Gas drying, water treatment, and fluoride sorption for various industrial applications. |

Innovation in molecular sieve technology continues to be driven by the pressing needs and challenges of various industries. Research initiatives are exploring the integration of molecular sieves with advanced materials, such as nanomaterials, to enhance their performance further. This can lead to increased adsorption capacities, improved kinetic properties, and the ability to target even smaller molecules effectively. The trend towards smart molecular sieves, which can give real-time data about their operational status and saturation levels, signifies a potential leap toward automation and enhanced operational efficiency.

Additionally, the demand for sustainable practices opens new avenues for molecular sieve applications. Coating molecular sieves with bio-based or recycled materials to enhance their sustainability profile is one area where research is promising. Integrating molecular sieves into biotechnological processes, such as biofuel production, could lead to significant improvements in yield and purity.

The collaboration among academia, industry, and technology providers will be paramount in driving these developments forward. As these efforts mature, we can expect to see Grace Molecular Sieve not just as a critical compositional material but as an integral part of innovative engineering solutions addressing the global need for cleaner, more efficient processes.

Real-world applications and user experiences can highlight the transformative effects that Grace Molecular Sieve has on operations across a range of industries. Several organizations have reported success stories illustrating the advantages of incorporating molecular sieves into their processes.

For instance, a leading petrochemical producer implemented Grace Molecular Sieve in their butane separation process, significantly increasing their yield by up to 20%. This improvement had a cascading effect, allowing them to maximize output and minimize waste, effectively lowering production costs and enhancing their market competitiveness. The case exemplifies the sieve's role in driving operational efficiencies in high-stakes environments.

In the pharmaceutical sector, a drug manufacturer faced challenges with moisture-sensitive compounds that were adversely impacting the stability of their formulations. By integrating Grace Molecular Sieve into their packaging processes, they managed to reduce moisture content significantly, resulting in an extended shelf life and improved product efficacy. This initiative also helped maintain compliance with regulatory standards for stability testing.

Moreover, in environmental applications, a municipality utilized Grace Molecular Sieve in its wastewater treatment facility to remove heavy metals from contaminated effluent. Implementing the sieve offered not only a more efficient removal mechanism but also lessened the overall treatment time, benefiting the operational flow and allowing for better compliance with environmental regulations. These stories collectively underscore the transformative impact of molecular sieve technology across diverse applications, positioning Grace as a leader in this field.

The journey into the realm of Grace Molecular Sieve highlights not only the technical excellence and broad applicability of this vital industrial component but illustrates a future where technology drives efficiencies, sustainability, and innovation. As industries continue to evolve and integrate advanced materials and processes, Grace Molecular Sieve will undoubtedly play a pivotal role in shaping the landscape of industrial operations, providing effective solutions to meet the complex challenges of the modern era. Through strategic partnerships, continuous research, and the relentless pursuit of innovation, the use of molecular sieves will evolve, ensuring that both industry and environment can thrive together in an ever-changing world.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!