This comprehensive guide explores Parker Proportional Valves, highlighting their importance in fluid control systems. These valves provide precise flow and pressure regulation, making them crucial for various industrial applications. Readers will gain insights into the operational benefits of these valves and their impact on enhancing system performance.

Parker Proportional Valves are an essential component of modern fluid control systems, known for their precision and reliability. These valves are integral in industries where exact control over fluid flow and pressure is necessary, such as in manufacturing, automotive, and aerospace sectors. With the increasing complexity of hydraulic and pneumatic systems, the demand for high-performance and responsive components such as Parker Proportional Valves has grown significantly. By providing proportional control, these valves allow for a wide range of adjustments to fluid parameters, making them indispensable in high-tech manufacturing environments and systems requiring fine control over mechanical movements.

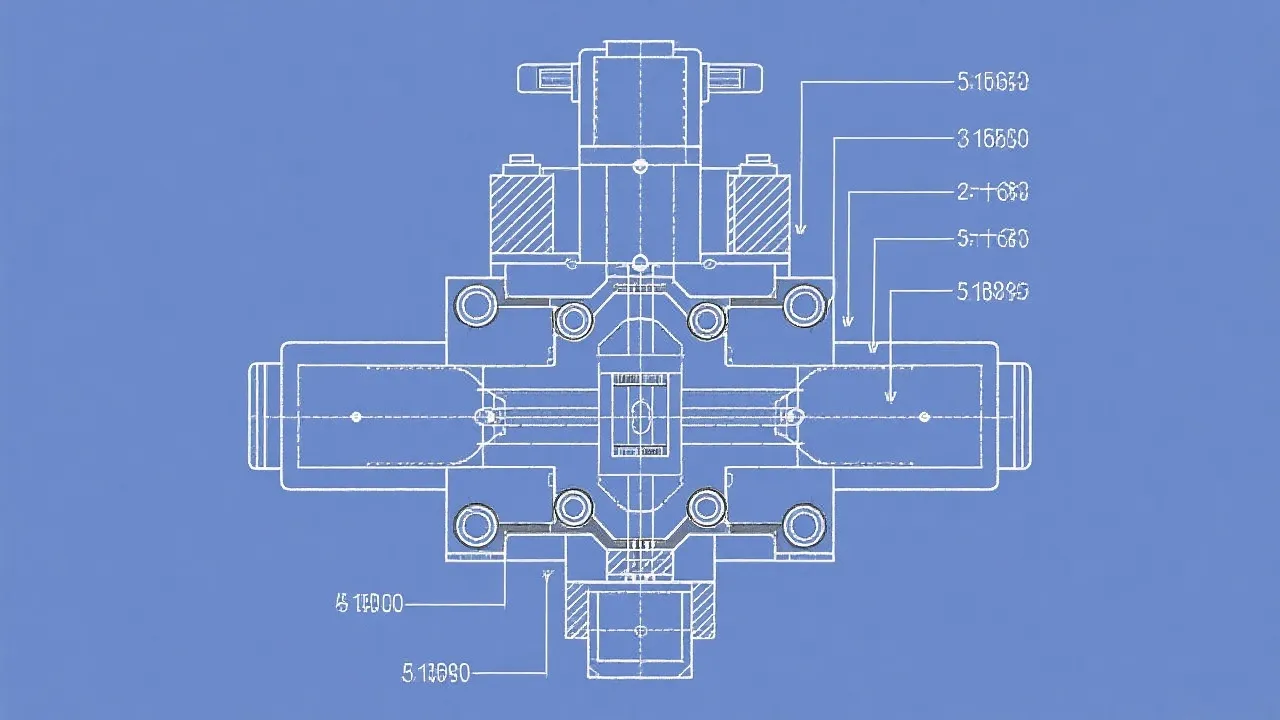

Parker Proportional Valves are designed to deliver precise control by varying the flow rate or pressure of fluids in a system proportionally to the input signal received. Unlike on/off valves, proportional valves provide a variable position for the valve spool, allowing for refined adjustments and improved system efficiency. This feature is particularly critical in applications that require changing operational conditions or dynamic adjustments based on real-time feedback. By utilizing electric signals to command the valve actuation, these proportional valves can adjust the flow continuously rather than in binary increments.

The advantages of using Parker Proportional Valves include enhanced system responsiveness, energy efficiency, and the ability to maintain consistent performance under varying operating conditions. These benefits contribute to reduced downtime and lower maintenance costs, making them a preferred choice in industrial applications. As industries strive for greater efficiency and reduced operational costs, the ability for proportional valves to fine-tune flow control plays a significant role in achieving these goals. Moreover, the implementation of these valves minimizes the risk of system shocks, which can lead to mechanical failures or inconsistent product quality.

Parker Proportional Valves are widely utilized in various industries:

Selecting the appropriate Parker Proportional Valve involves understanding the specific requirements of your application, including flow rate, pressure levels, and environmental conditions. There are multiple factors to consider, such as the valve’s size, the materials used in its construction, and the specific configurations that will be best suitable. Consulting with experts or suppliers can provide guidance to ensure the top fit for your system. Additionally, understanding the control method required—whether analog or digital—can influence the decision. The right choice will also incorporate assessing whether the valve needs to be fail-safe and if additional features such as diagnostic capabilities are necessary for your application. Ultimately, choosing the right valve can lead to improved operational efficiency and reliability in your fluid control systems.

| Feature | Benefit |

|---|---|

| Precision Adjustment | Allows fine-tuning of systems for better performance. |

| Compact Design | Facilitates installation in confined spaces. |

| Robust Material | Ensures longevity and resistance to wear and tear. |

| Easy Maintenance | Simplifies upkeep and enhances valve lifespan. |

| Versatile Connectivity | Compatible with various hydraulic systems for flexible installation. |

Regular inspections and cleaning are recommended to ensure optimal performance and longevity. Specific maintenance schedules depend on the environment and usage intensity. It’s essential to monitor the valve for signs of wear, leakage, or performance degradation and address these issues promptly to avoid larger problems. Maintaining a clean working environment around the valve can also prolong the life of its internal mechanisms, reducing the chance of contaminants interfering with operation.

These valves are generally suitable for a wide variety of fluids; however, it's important to verify the compatibility with specific fluid properties and conditions. Factors such as fluid viscosity, temperature, and chemical composition can affect valve performance. Consulting the manufacturer's guidelines can help in determining the best valve configuration for your specific application, ensuring reliable operation over time.

The precision control offered by Parker Proportional Valves can lead to significant energy savings by minimizing fluid waste and optimizing system operations. By allowing systems to operate closer to optimal parameters rather than in a binary fashion, these valves contribute to lower energy consumption and an overall reduction in operational costs. This control minimizes the need for excessive pump operation, which can lead to energy savings and enhanced system efficiency.

Yes, installing Parker Proportional Valves requires attention to several important factors, including orientation, sealing requirements, and the proximity of control signals. The installation configuration must be suitable for the specific application, and care should be taken to follow the installation instructions provided by the manufacturer to ensure optimal operation. Any misalignment or improper sealing can lead to performance issues or component failure, making careful installation critical.

The lifespan of these valves varies based on usage, environment, and maintenance practices. Typically, they are engineered for long-term reliability, often lasting for several years under optimal conditions. Regular maintenance and monitoring can help extend the lifespan significantly, allowing companies to maximize their investment in fluid control technologies.

Integrating Parker Proportional Valves into your fluid control system can significantly enhance performance, ensuring precise control and efficient operation. Their robust design and adaptable nature make them a valuable addition to various industrial applications, offering reliability and increased productivity. With their advanced engineering and commitment to quality, Parker continuously develops new technologies that improve the functionality and efficiency of fluid control systems, making them an industry leader. The move toward increased automation and energy efficiency in the global market further strengthens the relevance and application of Parker Proportional Valves across numerous sectors.

In conclusion, Parker Proportional Valves represent a critical advancement in fluid control technology, meeting the challenges of modern industrial demands with precision and reliability. Their design is focused on minimizing waste and maximizing performance, essential factors for businesses looking to improve profitability and reduce environmental impact. The ability to adjust flow and pressure dynamically based on real-time inputs greatly enhances the performance and versatility of various systems. By carefully selecting and implementing these valves, industries can achieve superior control, improve system reliability, and optimize their operations comprehensively. Investing in Parker Proportional Valves is a proactive step towards achieving operational excellence, ensuring that companies remain competitive in an ever-evolving market landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!