This comprehensive guide explores Rexroth Poppet Valves' functional mechanisms and applications. Esteemed for their reliability and precision, these valves are a crucial component in hydraulic systems across various industries. By examining their design and operational benefits, the article offers vital insights into why these valves are a top choice for engineers and manufacturers.

Rexroth Poppet Valves stand out in the fluid power industry due to their unique construction and adaptability in various applications. Renowned for precision and reliability, these valves play a pivotal role in controlling hydraulic systems efficiently. They offer a seamless solution to fluid management, essential for machinery that demands precision and durability. As industries evolve, the demand for advanced hydraulic solutions continues to rise, making technologies like Rexroth Poppet Valves increasingly vital. Their integration within complex hydraulic circuits safeguards functionality and ensures operational success across multiple sectors.

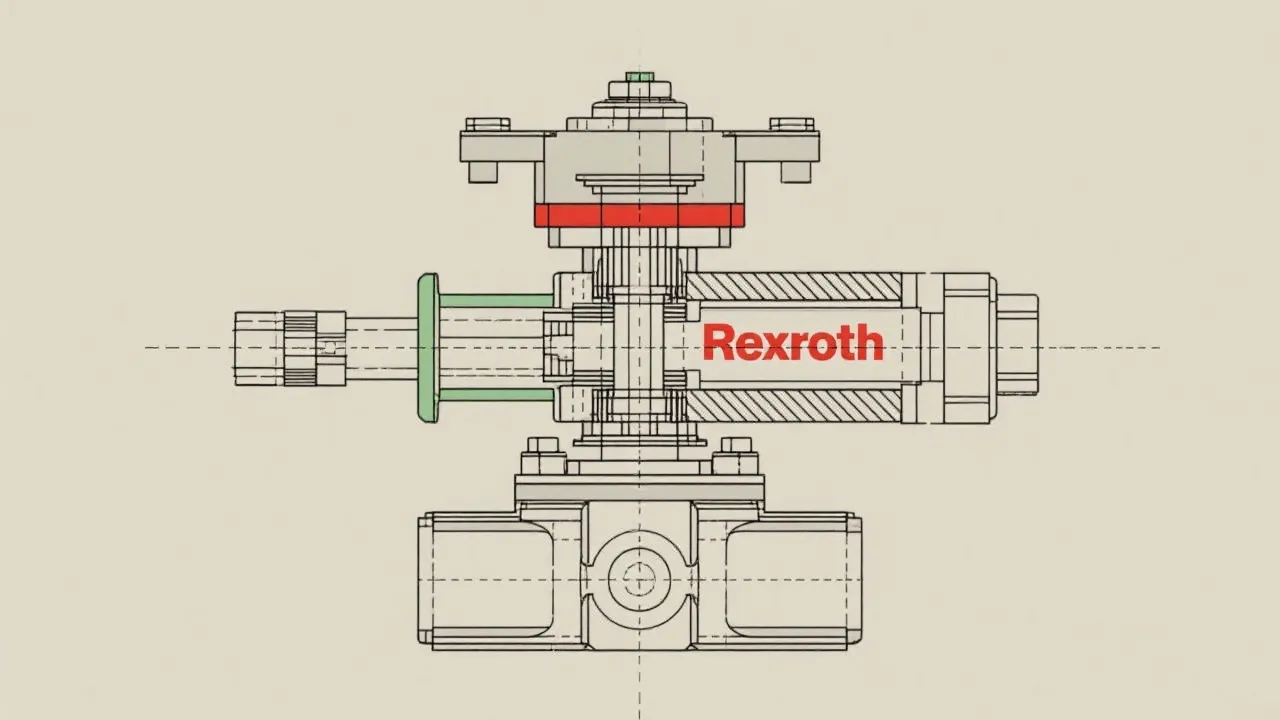

At the core of Rexroth Poppet Valves is their robust design, which consists of a poppet element that moves perpendicularly within the valve body to control fluid flow. Unlike conventional designs, their poppet arrangement minimizes leakage and maximizes responsiveness, streamlining the control of fluid footprint within hydraulic circuits. Such precision is especially valuable in industries like manufacturing, automotive, and aerospace, where exact fluid control is crucial. The operation principle relies on the poppet's seating mechanism, which effectively seals the valve when not in action, ensuring no fluid passes through, thereby preserving system integrity.

The materials used in the construction of Rexroth Poppet Valves further enhance their performance. Typically made from high-grade steel or specialized alloys, these materials provide strength and corrosion resistance, transcending the limitations presented by standard valve constructions. Additionally, precision machining processes ensure that every valve fits seamlessly into the intended application, removing any possibility of misalignment that may hinder performance.

These valves are extensively utilized in systems where controlled flow and pressure modulation are required. They find use in heavy-duty machinery, industrial automation systems, and high-pressure applications. Their ability to maintain operational stability under diverse conditions makes them indispensable in these sectors. Moreover, their design ensures reduced wear and tear, contributing significantly to the longevity of the systems they are installed in.

In manufacturing plants, for instance, Rexroth Poppet Valves control flow rates in hydraulic presses and injection molding machines, where precision is key to achieving desired product specifications. Furthermore, in the automotive industry, these valves manage hydraulic braking systems, ensuring rapid response and consistent performance, which are paramount for safety. In aerospace applications, they contribute to the functionality of landing gear and control systems, where reliability can mean the difference between success and failure.

Notable occurrences such as the increasing complexity of industrial automation also underscore the relevance of Rexroth Poppet Valves. As factories transition towards smart manufacturing, the precision and reliability offered by these valves align perfectly with the demand for responsive, efficient systems. Moreover, their ability to integrate with sensors and actuators further enhances their utility, making them a key component in modern fluid power systems.

From an expert perspective, Rexroth Poppet Valves offer unmatched performance metrics. Tests indicate that these valves can maintain a high degree of accuracy and responsiveness even under pressure fluctuations. Users have noted significant improvements in overall system efficiency and lifespan. Furthermore, their design simplicity aids in upkeep and reduces maintenance downtime, further enhancing their operational value.

Performance ratings often reflect their ability to operate consistently across a range of temperatures and pressures, making them suitable for nearly any environment encountered in industrial settings. Additionally, their inherent capability to manage surges and spikes in pressure without compromising their operational integrity is a hallmark of their advanced engineering.

Green initiatives in many industries further emphasize the importance of performance analysis in hydraulic systems. By adopting valves that minimize leakage and ensure maximum fluid utilization, companies are not only improving their mechanical efficiency but are actively contributing to environmental sustainability. Thus, using Rexroth Poppet Valves represents a strategic advantage, aligning technological innovation with eco-conscious operations.

| Feature | Rexroth Poppet Valve | Traditional Valves |

|---|---|---|

| Leakage Control | Minimal leakage due to poppet design | Higher leakage potential |

| Response Time | Highly responsive | Slower response |

| Durability | High, robust construction | Moderate, depending on usage |

| Maintenance | Simplified, less frequent | Complex, more often required |

| Pressure Rating | Extensive range, suitable for high-pressure applications | Limited to moderate pressure ranges |

| Weight | Lightweight, despite robust construction | Generally heavier, affecting system design |

Their design minimizes leakages and allows for rapid response during fluid control operations, critical for precision-heavy industries. The robust construction and advanced materials also contribute to maintaining performance under rigorous operating conditions.

Yes, Rexroth Poppet Valves are ruggedly built to withstand harsh conditions without compromising on performance or durability. Their construction employs seals and coatings that are resistant to extreme temperatures and pressures, making them suited for use in diverse climates and applications.

Due to their efficient design and minimal maintenance needs, they often result in prolonged service intervals, maximizing system uptime. With reduced frequency of necessary checks and repairs, industries can allocate resources more effectively, focusing on core operations rather than extensive maintenance routines.

Absolutely. These valves are designed for versatility, suitable for various applications from industrial automation to mobile equipment and aerospace. Their adaptability allows for seamless integration into existing systems, thereby enhancing performance across numerous sectors.

The expected lifespan can vary based on application conditions and maintenance practices, but under ideal conditions, these valves are known to last significantly longer than traditional valves due to their robust construction and reduced wear due to leakage. Users often report operational lifespans extending beyond two decades in well-maintained systems.

As technology progresses, R&D in poppet valves has led to innovations that enhance their performance further. Modern Rexroth Poppet Valves incorporate advanced design features such as integrated sensors that monitor pressure and flow in real-time, providing vital information that can be used to optimize system performance dynamically.

Moreover, the digitalization trend in hydraulic systems has paved the way for smart valves that communicate with central monitoring systems. This capability allows for predictive maintenance, alerting operators to potential failures before they occur, thereby minimizing downtime and enhancing overall system reliability. These advancements represent significant leaps toward integrating fluid power systems with Industry 4.0 standards, allowing for increased efficiency and data-driven decision-making.

The future of fluid power systems, including Rexroth Poppet Valves, is poised for significant transformations driven by advances in technology and sustainability concerns. Industries are leaning increasingly toward implementing IoT (Internet of Things) solutions that enable seamless interconnectivity between machinery and data systems, providing deep insights into operational performance.

Furthermore, as manufacturers strive to reduce their carbon footprints, there is a growing focus on developing hydraulic components that consume less energy and incorporate recyclable materials. Rexroth has already initiated protocols to ensure the environmental impact of their products is minimized throughout their lifespan.

As automation becomes the norm, the emphasis on enhancing precision and reducing waste translates into greater demand for high-performing components like Rexroth Poppet Valves. Both machine builders and system designers are looking to integrate these advanced components to ensure that they stay competitive in a rapidly evolving market.

Several industries have reported considerable success after implementing Rexroth Poppet Valves in their hydraulic systems. In one notable instance, a leading automotive manufacturer redesigned its entire hydraulic assembly using these valves, leading to an impressive 25% reduction in energy consumption and a notable increase in responsiveness during operation. The improved efficiency allowed the manufacturer to meet tighter production deadlines while maintaining quality standards.

In another case, an aerospace company faced challenges with their hydraulic landing gear system, particularly regarding reliability and response times. By switching to Rexroth Poppet Valves, they found a drastic improvement in performance, effectively reducing the failure rate of the landing gear mechanisms and enhancing safety across their fleet.

These case studies highlight the transformative potential of Rexroth Poppet Valves across sectors, where engineering solutions converge with operational needs to deliver exceptional results.

In summary, Rexroth Poppet Valves are a beacon of efficiency in hydraulic systems. By balancing precise control and robust construction, they provide unparalleled performance. Their adaptability across industries substantiates their position as an essential component in modern machinery. For industries striving for efficiency and reliability, choosing Rexroth Poppet Valves translates to longevity and optimal performance. As the landscape of fluid power technology continues to evolve, these valves remain at the forefront, exemplifying how innovation can lead to improved operational capabilities and sustainability within hydraulic systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!