This guide explores the intricate workings and applications of Rexroth poppet valves. Renowned for their durability and efficiency, these valves are pivotal in various industrial systems, offering reliability and precision. Understanding the mechanics and benefits of poppet valves can significantly enhance system performance.

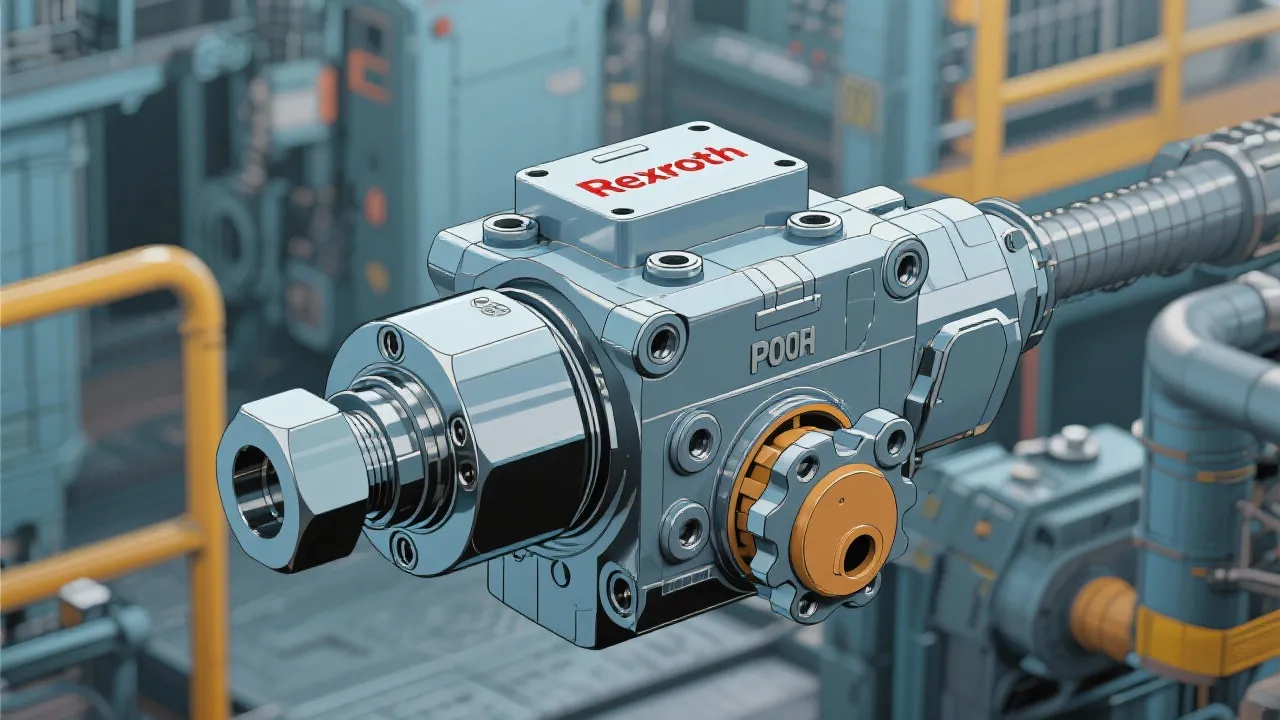

At the heart of many industrial hydraulic systems lies a component that carries significant importance—the poppet valve. Known for its robustness and efficiency, the Rexroth poppet valve stands out in the realm of fluid control devices. It is a type of valve that uses a cone-shaped stopper, or poppet, to seal the flow of fluids, ensuring that systems operate smoothly under variable conditions. Unlike other valve types that may have more complex mechanisms, the poppet valve's straightforward design contributes to its reliability and ease of maintenance, making it a preferred choice in many industrial applications.

The operation of a Rexroth poppet valve is based on the principles of hydraulic pressure and fluid dynamics. When the valve is closed, the poppet sits securely against the valve seat, effectively blocking the flow of fluid. This creates a pressure differential that can be exploited for various applications. Upon application of sufficient pressure on the inlet side, the poppet is forced away from the seat, allowing fluid to flow through the valve. This functionality makes Rexroth poppet valves particularly vital in scenarios requiring tight control of fluid dynamics, such as in hydraulic circuits wherein precise timing and modulation are paramount.

Rexroth poppet valves are celebrated for their tight shut-off capability, a trait that ensures minimal leakage and maximizes system integrity. This feature is particularly crucial in applications demanding precise pressure regulation. The design of these valves allows for quick response to changes in fluid dynamics, which is essential for maintaining the desired pressure and flow rates. Furthermore, the robust construction of Rexroth poppet valves means they can withstand harsh environmental conditions, which is a significant advantage in demanding industrial settings.

The material selection in Rexroth poppet valves contributes to their longevity and reliability. Using high-grade materials reduces the risk of wear and tear, ensuring that maintenance costs are kept to a minimum. Leveraging advanced manufacturing techniques, these valves provide consistent performance across varied operational scenarios, reinforcing the idea that they are among the most reliable components available in hydraulic systems. In addition, the simplicity of their design aids in achieving easier servicing and shorter downtime during maintenance procedures.

Beyond their core functionality, Rexroth poppet valves offer numerous advantages that enhance industrial applications:

These valves have a diverse range of applications across different industries. From manufacturing to heavy machinery and the automotive sector, Rexroth poppet valves contribute significantly to system efficiency and reliability. They are particularly useful in situations where high pressure and rapid response times are required, such as in hydraulic presses and injection molding machines. For instance, in the production of plastic components, the ability to manage precise fluid transfers under pressure is crucial for delivering consistent quality.

In the realm of construction, Rexroth poppet valves play a critical role in hydraulic excavators and backhoes, where they are pivotal in controlling the movement of buckets and other implements. These valves ensure that operators have precise control over their mechanisms, which is necessary for performing complex tasks such as grading or digging.

The automotive sector also benefits from Rexroth poppet valves with applications in braking systems, fuel systems, and power steering systems, where precise fluid control contributes to overall vehicle safety and performance. In these scenarios, the responsiveness and reliability of poppet valves are crucial as they often operate in high-stress environments where failure is not an option.

In addition, Rexroth poppet valves are utilized in the oil and gas industries, particularly in hydraulic fracturing operations, where they control fluid flow in high-pressure lines. Their capability to handle extreme conditions adds to their desirability in tough applications where safety and performance are non-negotiable.

| Feature | Rexroth Poppet Valves | Competitor Valves |

|---|---|---|

| Durability | High-grade materials for long lifespan | Variable quality materials |

| Response Time | Quick response to pressure changes | Slower response |

| Shut-off Capability | Tight seal with minimal leakage | Higher chances of leakage |

| Temperature Range | Operates effectively in extreme ranges | Limited temperature tolerances |

| Service Life | Longer operational life under various conditions | Shorter service life, requiring frequent replacements |

| Maintenance Frequency | Less frequent due to robust materials | Higher frequency due to wear |

| Cost-Effectiveness | Higher initial investment, lower overall lifecycle cost | Lower upfront cost, higher maintenance costs |

Proper installation of Rexroth poppet valves is crucial for optimal performance. It is advisable to follow manufacturer guidelines closely, ensuring that all components are correctly aligned and sealed. An incorrect installation can lead to insufficient sealing, resulting in leaks which not only waste fluid but can also damage equipment over time. Therefore, proper training of personnel involved in installation is essential.

Regular maintenance checks should be scheduled to inspect for wear and tear, particularly in demanding environments where pressure and temperature variations are frequent. Inspections should focus on the valve assembly, looking for signs of abrasion or damage on the poppet and valve seat. Additionally, checking the actuator operation can help prevent potential issues before they escalate.

In many cases, a more proactive maintenance approach will involve the periodic removal of valves to clean and inspect them thoroughly. This allows for the identification of any developing issues that could compromise performance down the line. Implementing a well-documented maintenance routine can also facilitate better tracking of valve performance and service intervals.

Furthermore, it is important to use compatible fluids in systems using Rexroth poppet valves. Incompatible fluids can cause chemical reactions leading to duress on valve components, ultimately diminishing their operation lifespan. Always consult the manufacturer's specifications when selecting hydraulic fluids.

What are the primary benefits of using a Rexroth poppet valve?

Rexroth poppet valves offer exceptional sealing capabilities, high durability, and fast response to pressure changes, making them ideal for a variety of industrial applications. Their ability to perform in adverse conditions while maintaining performance is unrivaled.

How do poppet valves differ from other types of valves?

Poppet valves use a cone-shaped stopper to control fluid flow, providing superior sealing compared to traditional gate or ball valves, especially in high-pressure scenarios. Their design simplicity aids in both performance and maintenance, making them a preferred choice in many sectors.

Are Rexroth poppet valves interchangeable with other brands?

While they may sometimes be compatible, it is recommended to use Rexroth components for guaranteed performance due to specific design and material considerations. Ensuring compatibility not only fosters effective operation but also minimizes the risk of failure in critical applications.

What types of fluids can be used with Rexroth poppet valves?

Rexroth poppet valves can handle a range of hydraulic fluids, including mineral oils and water-glycol solutions. For specific applications, consult Rexroth’s recommendations to ensure compatibility with the chosen fluid.

How can I ensure the longevity of my Rexroth poppet valves?

To ensure longevity, proper installation and regular maintenance are key. Adhere to recommended procedures, routinely inspect for wear, and use compatible fluids that correspond with the valve specifications provided by Rexroth.

What industries benefit the most from Rexroth poppet valves?

Industries that operate hydraulic systems, such as manufacturing, construction, and automotive, greatly benefit from Rexroth poppet valves due to their high performance, reliability, and ability to operate under demanding conditions.

In summary, Rexroth poppet valves present a reliable and efficient choice for fluid control in various industrial applications. Their design, focused on durability and precision, makes them an indispensable component in systems where performance and reliability are paramount. By choosing Rexroth, industries can enhance their operations, ensuring seamless and efficient fluid regulation. The combination of high-quality materials, effective performance in a wide range of applications, and ease of maintenance makes these valves a significant investment for businesses seeking to improve their hydraulic systems.

Moreover, as industries continue to advance and evolve, the role of fluid control systems will become increasingly critical. Therefore, selecting the right components, such as Rexroth poppet valves, is essential to not only meet current operational demands but also to future-proof systems against advancing technologies and increased performance expectations. In doing so, companies can ensure their hydraulic systems are robust and capable of withstanding the challenges of modern industrial applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!