This article delves into the intricacies of the LVDT proportional valve, a pivotal component in fluid control. These valves employ an LVDT sensor to provide precise feedback, ensuring accurate modulation of flow or pressure. As automation advances, these valves play a vital role in maintaining efficiency and reliability in industrial systems, underscoring their growing relevance.

The LVDT proportional valve is an essential component in modern fluid control systems, renowned for its precision and reliability. At the heart of its operation is the Linear Variable Differential Transformer (LVDT), a sensor that provides continuous feedback on position and movement, ensuring optimal control of flow or pressure in a system. These valves are ubiquitous in industrial settings, where their ability to maintain exact parameters is crucial for operational efficiency. From streamlining manufacturing processes to enhancing the functionality of sophisticated automation systems, LVDT proportional valves are pivotal in achieving optimal performance in fluid dynamics.

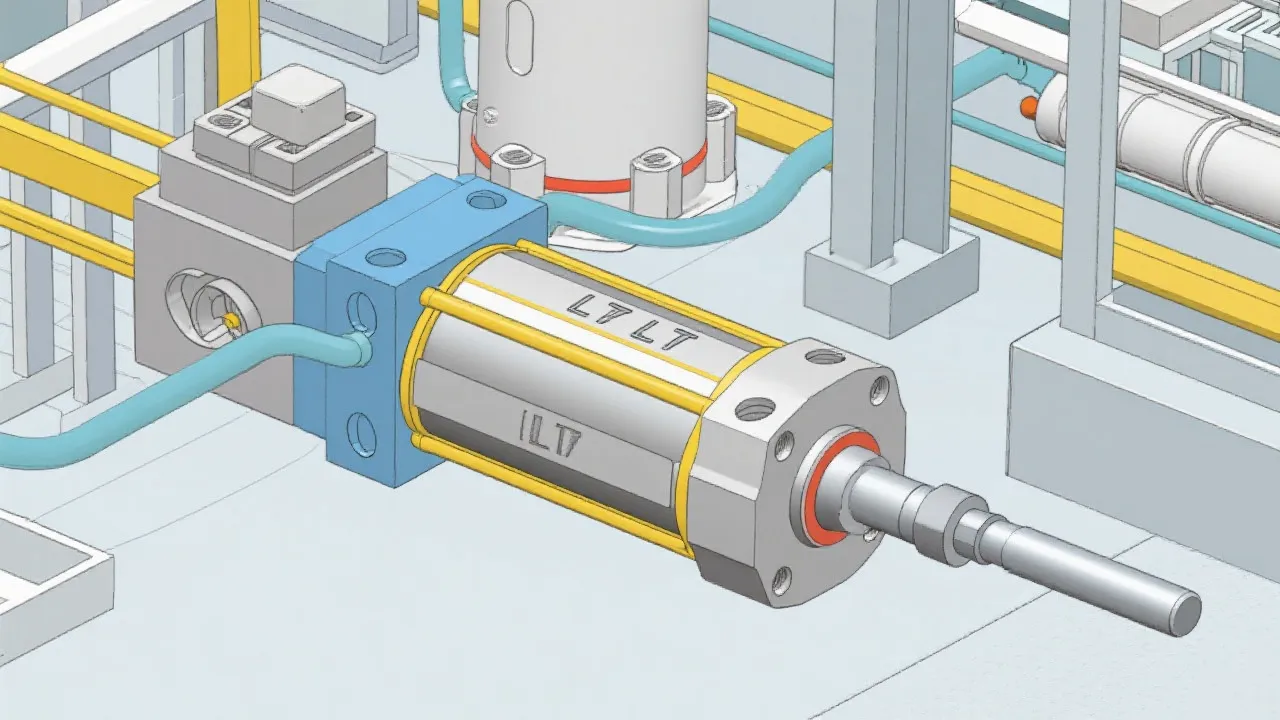

LVDT proportional valves function by using the LVDT to measure the position of the valve spool continuously. This measurement is converted into an electrical signal that provides real-time feedback to the control system, enabling precise adjustments. The typical configuration includes a solenoid coil within which the valve’s movable core slides, altering the magnetic field and thus the induced voltage. This design allows for sensitive and accurate control of hydraulic or pneumatic systems. Moreover, the dynamic nature of these devices ensures they can respond to changing demands instantaneously. This rapid response is particularly beneficial in scenarios where system conditions fluctuate frequently, requiring timely interventions to maintain desired flow rates and pressures.

| Component | Function |

|---|---|

| LVDT Sensor | Provides accurate position feedback of the valve spool, crucial for real-time adjustments. |

| Electromagnetic Coil | Generates the electromagnetic field for the LVDT operation, enabling accurate measurements. |

| Valve Body | Houses the internal components, designed to allow controlled fluid flow. |

| Control Circuitry | Processes the LVDT output to adjust the valve position, ensuring optimal system performance. |

| Power Supply | Provides electrical energy to the control circuitry and electromagnetic coil. |

| Feedback Mechanism | Ensures that outputs are matched with inputs for accurate system performance. |

The benefits of using LVDT proportional valves are numerous. Their high precision and reliability make them ideal for applications where exact control is paramount. This includes manufacturing, aerospace, and automotive industries. Additionally, LVDT proportional valves offer a non-contact measurement, which reduces wear and prolongs the component’s lifespan. Their ability to provide linear and stable control helps in achieving consistent performance in various operations.

Another significant advantage is their ability to maintain performance across a broad range of temperatures and pressures. This versatility makes them suitable for use in extreme environments, where traditional control methods may fail. Moreover, the straightforward implementation of LVDT technology allows for easier integration into existing systems, facilitating upgrades without extensive overhauls. The real-time feedback loop provided by LVDT sensors not only enhances reliability but can also lead to increased safety in operations, reducing the risk of catastrophic failures associated with improper fluid control.

LVDT proportional valves are extensively used in sectors such as manufacturing, where they control the flow of materials on production lines. For example, in a bottling plant, these valves can precisely manage the flow of liquid fill rates, ensuring that each bottle receives the correct amount of product with minimal waste. In the aerospace industry, they are vital for the hydraulic systems of aircraft, ensuring safe and efficient operations during takeoff, flight, and landing maneuvers. The automotive industry benefits from these valves in various vehicle control systems, providing stability and responsiveness in braking and suspension systems, significantly enhancing ride quality and safety.

Furthermore, the precision offered by LVDT proportional valves is critical in the healthcare industry, especially in devices and systems like infusion pumps and ventilators, where minute adjustments can make a significant difference in patient care. Their role in these applications highlights the importance of accurate fluid control in critical environments. The defense industry is another significant consumer of LVDT proportional valves, employing them in missile guidance systems or any mechanism where the precision of movement and response is mandatory. These diverse applications underscore the versatility of LVDT proportional valves and their importance across a multitude of sectors.

Technological advancements continue to enhance the functionality of LVDT proportional valves. Modern developments focus on increasing efficiency, minimizing response times, and integrating smart technology such as IoT to monitor and adjust systems remotely. For instance, using cloud-based analytics, engineers can predict when maintenance is needed, reducing unplanned downtime and optimizing system performance. These innovations are paving the way for more automated, efficient, and reliable industrial processes, reinforcing the importance of LVDT proportional valves in future applications.

Integration with machine learning algorithms is also becoming common, allowing systems equipped with LVDT proportional valves to learn and adapt to new operating conditions automatically. Such adaptability not only enhances performance but can lead to significant energy savings as the system optimizes its operations in real-time. Furthermore, advancements in materials and manufacturing processes are also contributing to the evolution of LVDT proportional valves, leading to lighter, more durable models capable of sustaining higher pressures and temperatures. This forward momentum in technology ensures that LVDT proportional valves will remain at the forefront of fluid control technology for years to come.

The maintenance of LVDT proportional valves is an essential aspect of ensuring their longevity and reliability. Regular checks should include visual inspections, operational tests, and performance audits. One critical aspect is to regularly examine the control circuitry for any signs of wear or damage. Since these components play a vital role in adjusting the valve position based on the feedback received, ensuring their proper functioning directly impacts the overall efficiency of the valve system.

Additionally, ensuring that the LVDT sensor is calibrated accurately is crucial for precise valve operation. Any misalignment or drift in the sensor's calibration can lead to incorrect feedback being sent to the control circuit, resulting in valve errors and potential system failures. Routine calibration checks should be performed according to the manufacturer's guidelines and the system's specific requirements.

Furthermore, it is important to maintain the cleanliness of components. Fluid contamination can lead to wear and tear of the valve internal components, subsequently affecting performance. Utilizing filters in conjunction with LVDT proportional valves can greatly reduce the risk of particle-induced damage. Lastly, implementing a predictive maintenance schedule can minimize emergency repairs and prolong the operational life of these critical components.

Despite their numerous advantages, LVDT proportional valves do face certain challenges. Environmental factors can significantly impact their performance. For example, exposure to dust, moisture, or high temperatures can affect the LVDT's sensitivity and accuracy. To combat these challenges, manufacturers often use protective housing and coatings, but there are limits to how much these measures can mitigate adverse conditions.

Moreover, the complexity of installation and integration can pose challenges, especially in retrofitting existing systems. Engineers may encounter difficulties in ensuring compatibility with old equipment or in configuring new systems to capitalize on the new valve technology effectively. A thorough assessment and planning process is essential in overcoming these hurdles.

Another challenge is the cost associated with high-precision LVDT proportional valves. While they provide significant advantages, their sophisticated technology can lead to higher upfront costs, which can deter some organizations from implementation. However, the long-term benefits of increased efficiency and reduced operational costs often justify the initial investment.

Finally, with the evolution of technology, there are numerous competing technologies that may threaten the dominance of LVDT proportional valves. Alternative technologies, such as smart valves with built-in sensors and solenoids, are gaining traction. Staying informed about industry advancements and maintaining adaptability will be crucial for the ongoing relevance of LVDT proportional valves in the future.

As industries increasingly focus on automation and efficiency, the future of LVDT proportional valves looks promising. One trend is the incorporation of artificial intelligence (AI) to enhance predictive maintenance and real-time adjustments based on system performance and changing operational conditions. This allows facilities to minimize downtime and increase production rates significantly, showcasing how LVDT proportional valves can be integrated into the smart factories of the future.

Another trend is the move towards more compact and lightweight designs. As automation scales up, there will be a greater need for LVDT proportional valves to fit within smaller spaces while still providing reliable performance. Innovations in miniaturization and materials will enable these valves to be both space-saving and efficient.

Additionally, there is a growing emphasis on sustainability in engineering practices, and LVDT proportional valves are no exception. Manufacturers are being challenged to create solutions that are not only efficient but also environmentally friendly. This includes using sustainable materials and designing products for optimal energy efficiency, reducing operational footprints.

Furthermore, as the Internet of Things (IoT) revolutionizes industries, LVDT proportional valves are being integrated into networked systems where they can communicate with other devices, facilitating comprehensive monitoring and automation. This connectivity not only optimizes process control but also enhances data collection for analysis, leading to improved decision-making processes.

The increasing reliance on data analytics will also shape the future of LVDT proportional valve technology. Companies will leverage data to optimize their systems continually, making adjustments to increase responsiveness and efficiency. The infusion of these technologies reinforces the position of LVDT proportional valves as a critical component in evolving industrial landscapes.

In summary, LVDT proportional valves are an integral part of many modern control systems, offering precision and durability necessary for efficient operations. As industries lean towards more complex and automated systems, the demand and reliance on these valves will likely continue to grow. Understanding their function and advantages is pivotal for engineers and decision-makers aiming to enhance system reliability and efficiency. The ongoing advancements in technology promise to further bolster their capabilities, ensuring that LVDT proportional valves will remain a cornerstone of fluid control solutions in a wide array of applications and industries. As we move into a more digitalized and automated age, these valves will undoubtedly adapt and thrive, reinforcing their position as indispensable components within sophisticated engineering ecosystems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!