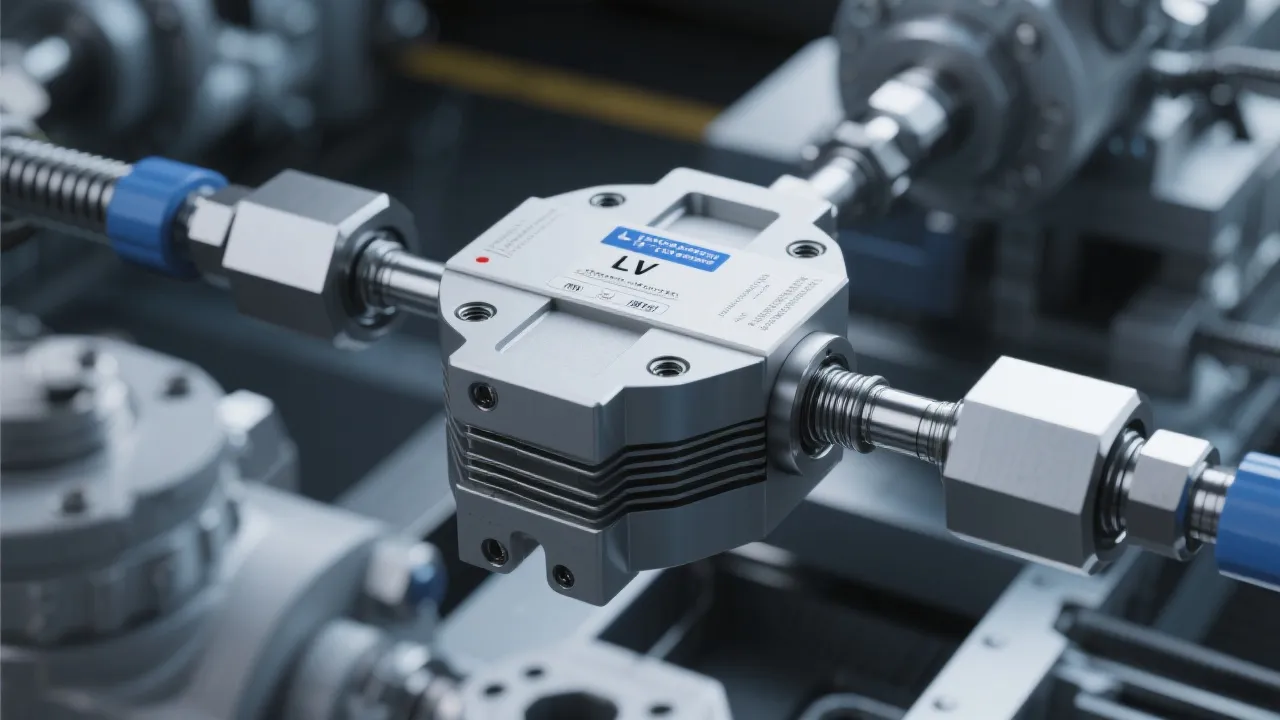

This article delves into the intricacies of Lvdt Proportional Valve technology, a crucial component in modern industrial automation systems. These valves provide precise control over fluid flow, enhancing the efficiency of hydraulic and pneumatic systems. Their application spans a wide range of industries, including manufacturing, aerospace, and energy, due to their reliability and precision.

In the realm of industrial automation, the Lvdt Proportional Valve represents a pinnacle of precision and control. These advanced components are essential in managing fluid dynamics across various systems, ensuring optimal performance and efficiency in myriad applications. As industries increasingly pivot towards automation, the demand for precise and reliable components such as Lvdt Proportional Valves is set to grow. In a landscape where efficiency and performance are paramount, incorporating Lvdt Proportional Valves can significantly enhance the operational capabilities of various machinery and systems, contributing to overall productivity.

Lvdt Proportional Valves are integral components used to regulate the flow of liquids or gases within a circuit. The LVDT (Linear Variable Differential Transformer) technology embedded within these valves enhances their functionality by providing precise positional feedback. This capability is crucial for maintaining the required flow rate in diverse applications, from manufacturing processes to aerospace engineering. By employing feedback mechanisms, these valves can adjust their position dynamically, ensuring that delivery pressure and flow rates are consistently maintained within specified limits, thus improving system performance.

The operational principle of Lvdt Proportional Valves relies predominantly on electromagnetic induction, wherein the coils of the LVDT generate a signal proportionate to the displacement of the valve’s core. This displacement directly correlates to the change in flow rate, allowing operators to finely tune processes according to real-time requirements. This characteristic makes them extremely beneficial in applications requiring quick adjustments to flow characteristics, such as in chemical mixing or temperature control systems.

The primary advantage of employing Lvdt Proportional Valves lies in their ability to offer precise flow control even under variable conditions. This accuracy is particularly beneficial in critical industries such as pharmaceuticals, where exact dosages and flow rates are imperative. Additionally, their robust design ensures reliability and durability in harsh environments, making them suitable for heavy-duty applications. The technological integration of LVDT allows for superior performance metrics, enabling these valves to maintain accuracy across a wide range of operational settings.

Moreover, the energy efficiency of Lvdt Proportional Valves cannot be understated. By enabling precise flow control, these valves minimize energy loss and reduce operational costs, which is a critical consideration in modern industrial setups focused on sustainability. The adaptability of these valves to integrate with existing automation systems also simplifies their deployment, allowing for seamless upgrades to current infrastructures without requiring extensive overhauls.

Lvdt Proportional Valves find applications across a broad spectrum of industries:

Lvdt Proportional Valves are designed with specific technical facets that cater to high-performance requirements:

| Feature | Description |

|---|---|

| Material | Constructed from corrosion-resistant alloys for extended lifespan, such as stainless steel, which withstands both temperature and chemical corrosion. |

| Feedback System | Integrated LVDT for continuous positional feedback ensuring accuracy, facilitating real-time adjustments based on operational requirements. |

| Flow Rate Range | Varies to suit different industrial needs, offering flexibility and adaptability. They can accommodate flow rates from low-pressure gentle flows to high-pressure applications. |

| Size and Configuration Options | Available in multiple sizes and configurations, making them versatile for a plethora of applications. |

| Response Time | Rapid response times, often within milliseconds, allow for immediate adjustments based on fluctuations in system parameters. |

| Power Consumption | Low power consumption compared to traditional valve mechanisms, contributing to improved energy efficiency in systems. |

Ensuring the longevity and reliability of Lvdt Proportional Valves can be achieved through regular maintenance checks. Industries should invest in periodic inspections and calibrations to prevent wear and manage replacements as necessary, thus minimizing downtime and optimizing system performance. Implementing a proactive maintenance schedule allows operators to identify potential issues before they escalate, ensuring that production schedules are not disrupted.

Moreover, the integration of remote monitoring systems can enhance maintenance strategies. By employing predictive analytics, operators can anticipate wear patterns and schedule maintenance during non-peak hours, thereby maximizing equipment availability. Such technologies can also track valve performance metrics over time, offering data-driven insights into efficiency and possible areas for improvement.

Installing Lvdt Proportional Valves requires careful planning and adherence to industry best practices. Here are steps typically followed in the installation process:

Beyond its primary function within proportional valves, LVDT technology is extensively utilized in various automation systems. The adaptability and precision of LVDT make it suitable for numerous applications, including:

The future of Lvdt Proportional Valve technology is poised for substantial advancements. With the ongoing evolution in industrial automation and smart manufacturing, several trends are emerging:

Here we address some frequently asked questions about Lvdt Proportional Valves:

As industries continue to evolve with an emphasis on precision and efficiency, Lvdt Proportional Valves stand out as a cornerstone technology in flow regulation systems. Their versatility and accuracy not only streamline operations but also promise future advancements in industrial applications, cementing their importance in the trajectory of technical advancements. The ongoing integration of cutting-edge technologies, such as IoT and AI, will only serve to enhance the capabilities of these valves, making them even more indispensable in modern industrial processes. With the growing focus on automation and efficiency, Lvdt Proportional Valves are set to be at the forefront of innovation, shaping the future landscape of industrial automation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!