The Lvdt Proportional Valve is an integral component in precision control systems, enhancing fluid pressure regulation across various industries. This article explores the technical attributes, advantages, and applications of Lvdt Proportional Valves, providing insights from industry experts to help you understand their role in modern engineering.

In the realm of hydraulic and pneumatic controls, the Lvdt Proportional Valve represents a pinnacle of precision technology. These valves play a crucial role in regulating fluid pressure and flow, enhancing the performance of systems where precise control is paramount. Characterized by the integration of a Linear Variable Differential Transformer (LVDT), these valves are designed to maintain consistent modulation of fluid forces, making them indispensable in sectors such as aerospace, automotive, and industrial automation.

As industries become more automated and interconnected, the demand for precision control solutions has surged. Lvdt Proportional Valves answer this need through their advanced design and functionality. Leveraging sophisticated technologies such as real-time feedback and high responsiveness, these valves ensure that fluid systems operate in an optimized manner, benefiting from greater efficiency and reduced wear. Their ability to seamlessly integrate into complex systems allows for innovative solutions that push the boundaries of hydraulic and pneumatic control technology.

An Lvdt Proportional Valve distinguishes itself through its embedded LVDT feedback mechanism, which provides real-time position feedback of the valve spool. This feedback loop ensures that the valve responds proportionally to the input control signal, adjusting the fluid flow effectively. This capability allows for meticulous control over various parameters such as speed, position, and pressure, optimizing the overall system functionality.

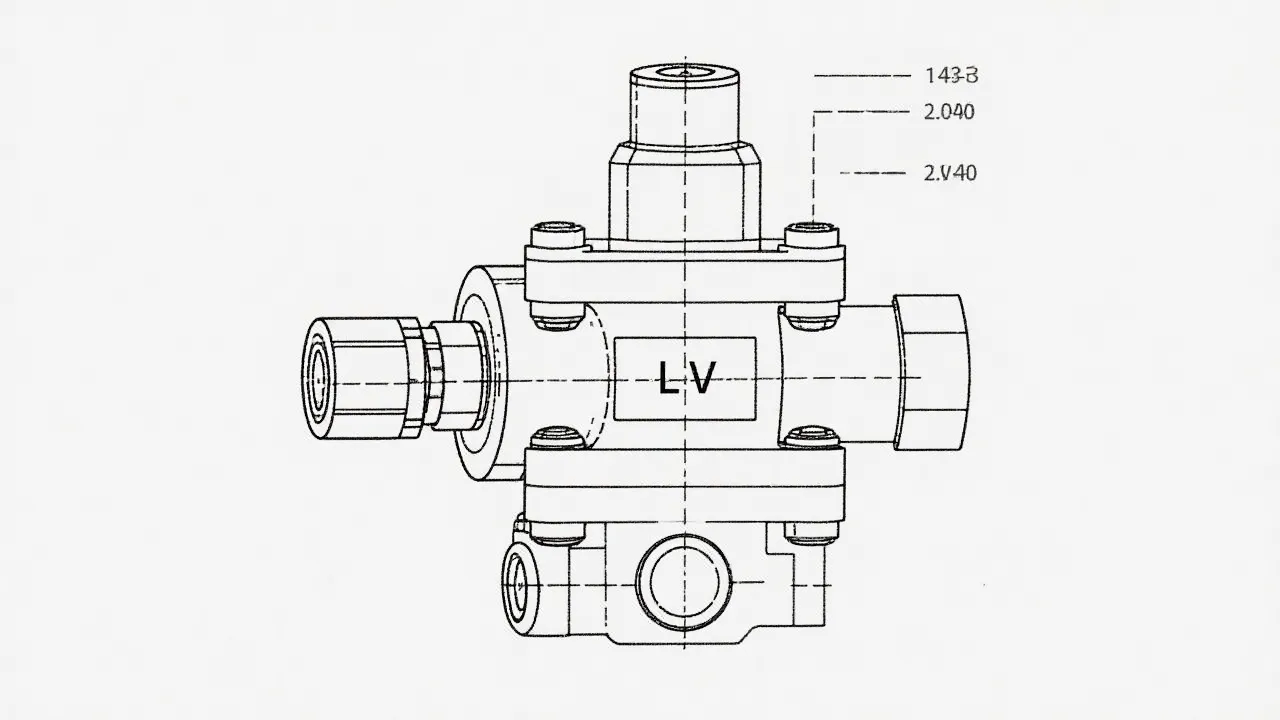

The LVDT component offers exceptional reliability because it operates without physical contact, minimizing wear and tear, therefore extending the service life of the valve. Typically, these valves are constructed from robust materials such as stainless steel or aluminum, providing resistance to harsh environmental conditions. Additionally, their construction can vary to suit specific applications, ranging from inline setups to block-mounted configurations.

The configuration of an Lvdt Proportional Valve includes several critical components: the valve body, the spool, the LVDT sensor, and the actuator. The valve body houses the spool and, when energized, allows for variable fluid flow through passageways. The spool is designed with specific shapes that determine orifices through which the fluid passes, thus controlling the flow rate. The LVDT sensor continuously measures the spool's position, sending feedback to an electronic controller, which adjusts the actuator's movement accordingly.

Moreover, these valves can be operated using various input signals (such as analog voltage or current), allowing them to connect to different control systems without significant modifications. This flexibility is crucial in applications that may require different control strategies based on varying operational demands. For instance, some industries utilize cascading control loops when implementing Lvdt Proportional Valves, allowing for enhanced precision during dynamic operations.

The adaptability of Lvdt Proportional Valves makes them suitable for an impressive array of industrial applications. In aerospace, they ensure precise control of hydraulic systems vital for aircraft maneuverability. Automotive industries rely on these valves for refining vehicle dynamics and stability controls. Moreover, in industrial manufacturing, Lvdt Proportional Valves optimize machinery performance, thereby enhancing production efficiency.

Each application benefits from the valve's ability to provide seamless transition between different states of flow, with instantaneous feedback allowing for corrections that maintain desired system outputs. Such precision ensures minimal energy loss and maximizes operational throughput.

In the aerospace industry, for example, Lvdt Proportional Valves are used in flight control systems where dynamic response to pilot inputs is critical. By maintaining precise control over the hydraulic actuators that move flight surfaces, these valves contribute to the overall safety and responsiveness of aircraft. Furthermore, they play a role in systems managing the landing gear, ensuring a proper retraction and extension sequence during takeoffs and landings.

In automotive applications, Lvdt Proportional Valves help in electronic stability programs, traction control systems, and advanced suspension setups. These valves can modulate fluid forces acting on shock absorbers, enhancing ride quality and vehicle handling. The feedback mechanism allows for real-time adjustments based on driving conditions, thus improving both safety and comfort for passengers.

In industrial applications, they are widely used in manufacturing processes where precise fluid control is necessary. For instance, in plastic molding processes, Lvdt Proportional Valves can control the flow of hydraulic oil used to actuate molding presses, ensuring that mold fills occur at the optimum pressure and speed, leading to high-quality finished products and reduced cycle times.

In addition to these core advantages, Lvdt Proportional Valves facilitate easier integration with modern control systems, including digital control interfaces and programmable logic controllers (PLCs). The ability to connect these valves to smart manufacturing systems through protocols like CAN bus or Ethernet/IP allows for improved monitoring and data collection, leading to further operational insights and optimizations.

After implementing the above steps, it is crucial to monitor the system performance continuously. Collecting data over time can help identify areas for further improvement and recognize trends that may necessitate adjustments to the valve setup. Regular performance reviews can extend the service life of the valve and lead to more reliable operations.

| Technology | Advantages | Disadvantages |

|---|---|---|

| Lvdt Proportional Valve | Precise feedback, durable, energy-efficient | Higher upfront cost |

| Servo Valves | Excellent control, fast response times | More complex, costly maintenance |

| On/Off Valves | Simplicity, low cost | Limited control, less precise |

| Pneumatic Regulating Valves | Good for lower pressure applications | Less efficient, not suitable for high precision applications |

The choice between these technologies should be informed by specific application demands and economic considerations. For instance, while on/off valves can be suitable for simple systems, they do not offer the fine control required in high-performance applications. Conversely, although servo valves provide superior control, their complexity and maintenance costs may deter some applications, particularly where budget constraints are a significant concern. Thus, making informed decisions by understanding both the advantages and limitations of each technology is critical in optimizing operations.

In conclusion, Lvdt Proportional Valves serve as a critical component in the toolkit of modern engineering solutions. Their precision, versatility, and efficiency ensure their prominent role across industries, revolutionizing how fluid control systems operate in complex applications. By investing in these advanced valves, industries not only enhance operational reliability but also achieve new levels of performance, synonymous with cutting-edge technology and innovation.

Ultimately, the forward journey of system control involves leveraging technologies such as Lvdt Proportional Valves that complement automation trends and industry 4.0 initiatives, paving the way for smart manufacturing and enhanced production capabilities. As organizations begin to recognize the advantage of real-time data and operation adjustments, the integration of precision control systems like these valves will become a standard practice, augmenting overall effectiveness and creating opportunities for efficiency gains. Such advancements promise to shape the future landscape of industrial automation, ensuring that organizations remain competitive in an ever-evolving market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!