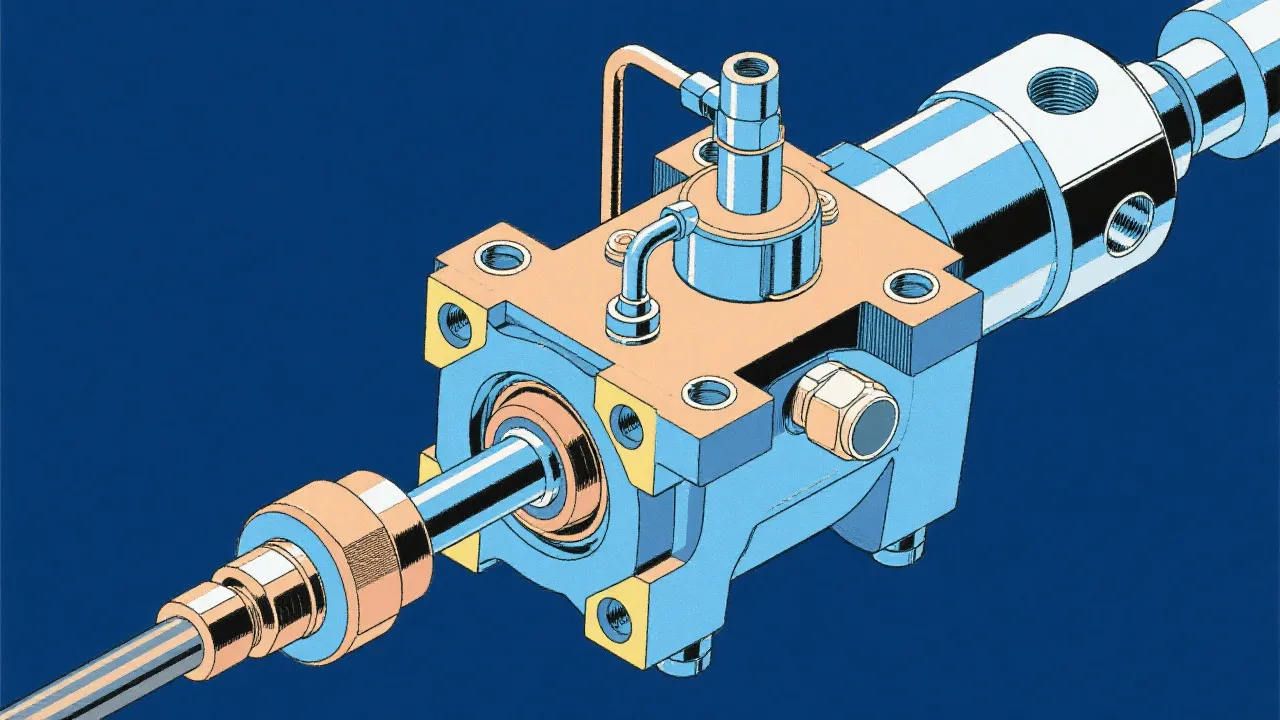

The Lvdt Proportional Valve is a crucial component in many industrial applications, offering precision in fluid control. Vital in sectors like aerospace and automotive, this device integrates an LVDT sensor that provides accurate feedback mechanisms needed for real-time adjustments and improved efficiency. Design intricacies contribute to its popularity and efficacy in a wide range of uses.

The Lvdt Proportional Valve is a sophisticated instrument pivotal to industries that require precise control of fluid dynamics. Encompassing the fusion of Linear Variable Differential Transformers (LVDTs) with proportional valves, this device is lauded for its versatility and accuracy in modulating fluid flow. Predominantly employed in industrial applications such as aerospace, automotive, and heavy machinery, Lvdt Proportional Valves are essential for tasks demanding exactitude and consistency. As industries strive for greater efficiency and sustainability, the role of these valves becomes increasingly critical, ensuring that fluid systems operate with minimal waste and maximum control.

Understanding the importance of Lvdt Proportional Valves necessitates a delve into their core functionality. These valves combine traditional servo valve mechanisms with the precision of an LVDT feedback loop, allowing for exact positioning and movement control. The integration of these technologies results in significant operational efficiency, minimizing fluid leakage and optimizing energy use. With the capability to respond instantaneously to control signals, these valves enhance system responsiveness, which is crucial in dynamic industrial environments. As industries pivot toward more sustainable and energy-efficient models, the demand for such precise control technology has surged, making Lvdt Proportional Valves a focal point in modern engineering practices.

Lvdt Proportional Valves are widely acknowledged for their applications across various sectors:

The heart of the Lvdt Proportional Valve lies in its ability to modulate fluid flow with unparalleled accuracy. The inclusion of an LVDT sensor amplifies this capability. The sensor functions by measuring the position of the valve spool in real time, providing feedback to the control system which adjusts the valve's position as required to maintain the desired flow rate. This feedback loop ensures that the system adapts proactively to changes, enhancing performance and mitigating risks associated with overshooting or undershooting.

The operational efficiency of Lvdt Proportional Valves is further enhanced by their compact design, which allows for integration into various systems without significant redesigns. Their ability to handle a wide range of fluid types and operating conditions makes them highly versatile and a common fixture in both new and retrofitted systems.

Key technical specifications often seen in Lvdt Proportional Valves include:

While Lvdt Proportional Valves present numerous advantages, their implementation is not devoid of challenges. Some of the primary concerns include:

| Challenge | Solution |

|---|---|

| Complex Setup | Requires skilled technicians; investing in thorough training can mitigate this challenge by ensuring operators fully understand system integration and troubleshooting. |

| Maintenance | Routine checks and calibration can prevent malfunctions, ensuring good operability. Establishing a predictive maintenance schedule can help anticipate wear and address it proactively. |

| Cost | Although the initial investment may be high, the good savings in energy efficiency and operational reliability often outweigh upfront costs. Conducting a cost-benefit analysis can provide insight into long-term advantages. |

| Integration with Legacy Systems | Implementing newer technology into older systems can be difficult; utilizing adaptable control systems that can interface with legacy technologies can allow for smoother transitions. |

| Environmental Considerations | In applications where environmental impacts are of concern, selecting materials for the valves that are resistant to corrosion or degradation can prolong service life and reduce the need for replacements. |

What is the primary benefit of using Lvdt Proportional Valves?

These valves offer precise control of fluid flow, which is essential in industries requiring exact positioning and movements. The ability to make fine adjustments quickly leads to enhanced operational efficiency and safety.

How do Lvdt Proportional Valves work?

They integrate an LVDT sensor with a proportional valve to provide real-time feedback, allowing for precise adjustments in fluid flow. This closed-loop control system ensures optimal performance and responsiveness.

Are Lvdt Proportional Valves suitable for all industrial applications?

While they are versatile, their use is particularly beneficial in applications where precision and control are critical, such as in aerospace and automotive sectors. However, proper evaluation of application requirements is crucial before adoption.

What maintenance do Lvdt Proportional Valves require?

Regular calibration and checks are necessary to maintain accuracy and prevent potential malfunctions. It is also advisable to perform periodic cleaning of the valves to ensure that no debris impedes functioning.

Can Lvdt Proportional Valves be used in corrosive environments?

Yes, but it is important to specify materials and coatings that can withstand corrosive substances. Understanding the fluid being managed and selecting compatible materials can enhance durability even in harsh environments.

The Lvdt Proportional Valve stands as a testament to the evolution of fluid control technology, encapsulating innovation and efficiency. As industries worldwide continue to advance, the role of such precision components becomes ever more significant. These valves are not merely tools; they are key contributors to the progress of industrial automation, green technology, and safety enhancements across the board. While the journey to perfect integration poses challenges, the strategic advantages and enhanced operational capabilities they offer affirm their pivotal role in modern industrial landscapes.

As industries are increasingly pressed to adopt sustainable practices and energy-efficient technologies, Lvdt Proportional Valves will play a crucial role in shaping the future of fluid dynamics. Their capacity to optimize system performance while reducing waste positions them at the forefront of technological advancements in automation and control systems. By embracing such innovations, industries can not only improve their operational efficiencies but also contribute to broader ecological goals, setting a foundation for sustainable growth in the face of a rapidly changing global landscape.

Looking ahead, ongoing research and development in the field of fluid control technologies promise even greater advancements in Lvdt Proportional Valves, including improved materials, smarter technologies, and enhanced integration capacities. As a result, these devices are poised to remain integral components in the evolution of industrial processes, driving new levels of efficiency, reliability, and sustainability.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!