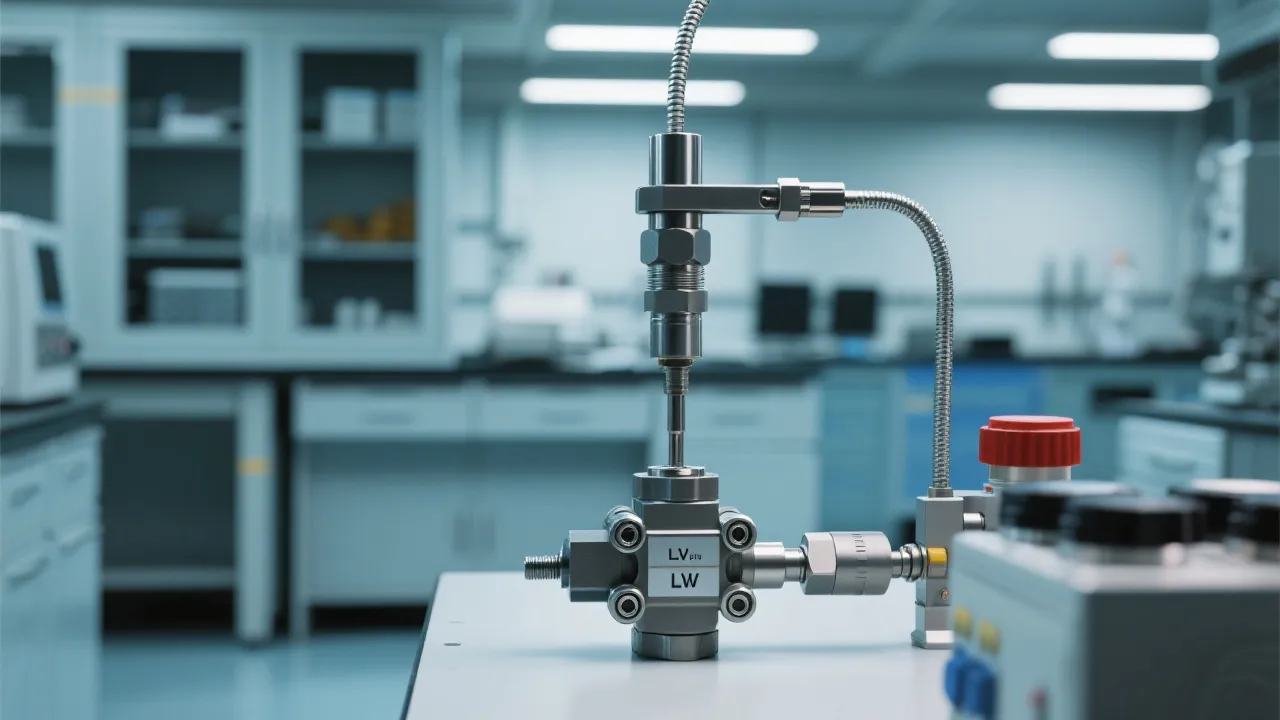

The LVDT Proportional Valve stands as a pivotal component in precise fluid control systems, widely used across various industrial sectors. Known for its reliability and accuracy, this valve ensures the effective modulation of flow, pressure, and temperature, thus maximizing operational efficiency and reducing waste. As technology advances, these valves integrate seamlessly with modern control systems, offering enhanced performance and adaptability.

The Linear Variable Differential Transformer (LVDT) Proportional Valve is an advanced piece of equipment crucial for precise fluid control across numerous industries. Characterized by its ability to provide consistent and accurate control over flow and pressure, the LVDT Proportional Valve plays an indispensable role in systems demanding high precision. The operation and effectiveness of these valves are evidenced by their increasing implementation in various applications, facilitating advancements in technology and enhancing efficiency in operations.

The primary feature of the LVDT Proportional Valve is its high-resolution position feedback, which ensures accurate control of actuator displacement. This is pivotal in applications requiring tight tolerance such as aerospace, automotive, and manufacturing. The integration of LVDT technology with the proportional control valve allows for real-time adjustments, enhancing system responsiveness and efficiency. The ability to monitor and adjust system performance dynamically makes the LVDT Proportional Valve ideal for environments where conditions can rapidly change.

Other advantages include durability and minimal maintenance requirements. Unlike other feedback mechanisms, LVDTs are contactless, reducing wear and tear. This feature, combined with robust construction materials, extends the operational lifespan while minimizing downtime. Moreover, LVDT Proportional Valves have a low power consumption profile, which further optimizes efficiency, particularly in large-scale systems that operate continuously. Their energy efficiency contributes to broader sustainability goals by decreasing the energy footprint of industrial processes.

The precise movement and control offered by LVDT Proportional Valves also translate into enhanced process stability. This improved stability means that systems can operate at peak efficiencies, leading to better end products and reduced operational costs. The rapid response times enable systems to function more smoothly, reducing the likelihood of mechanical failures or interruptions in production.

From a technical standpoint, the LVDT Proportional Valve operates by converting mechanical position into an electrical signal. This electronic signal directly correlates with the valve position, allowing for precise control governed by the input voltages. The seamless integration of this technology within larger control systems is crucial for maintaining high performance and reliability. This is primarily accomplished through the use of closed-loop control systems, where the output position is constantly monitored and adjustments are made as necessary to maintain target values.

The construction of an LVDT includes a primary coil and two secondary coils arranged symmetrically on either side of the primary. As the core moves within these coils, the output voltage changes, which is then used as feedback to adjust the valve position accurately. This setup allows for a high degree of sensitivity and resolution, enabling the valve to respond to even the slightest changes in position or pressure.

Another key technical aspect of LVDT Proportional Valves is their ability to operate across a wide range of temperatures and environmental conditions. This adaptability makes them suitable for use in industries like oil and gas, where extreme conditions are commonplace. Furthermore, LVDTs can withstand contamination from fluids, ensuring consistent performance even in harsh environments, which is a significant consideration in industrial applications.

Industries leveraging LVDT Proportional Valves include aerospace, where they manage hydraulic controls in aircraft; automotive, specifically in applications involving suspension systems and fuel regulation; and industrial automation, controlling various aspects of production lines and robotic systems. These valves provide the precision required to meet stringent industry standards and improve overall system performance. In aerospace, for example, LVDT Proportional Valves control the movements of wing flaps and other aerodynamic surfaces, directly contributing to flight safety and efficiency.

In the automotive industry, the application of LVDT technology extends to advanced driving assistance systems (ADAS), where precise control over hydraulic systems is needed for improved vehicle dynamics. This capability enhances safety features in vehicles, such as anti-lock braking systems (ABS) and electronic stability control (ESC), which rely on accurate and rapid response times for optimal performance.

Industrial automation also significantly benefits from LVDT Proportional Valves in maintaining product quality and consistency during manufacturing. Automated systems can leverage these valves for precise control of fluid flows and pressures in processes like injection molding, packaging, and surface treatment. By ensuring that the right amount of material is delivered exactly when needed, manufacturers can reduce waste and improve yield rates across production lines, leading to increased profits and sustainability.

The LVDT Proportional Valve market is experiencing significant innovations driven by advancements in technology and increasing demands for automation. As industries look to implement more efficient and precise control systems, the development of smart valves incorporating Internet of Things (IoT) technology is gaining traction. These smart valves can offer advanced diagnostics, predictive maintenance capabilities, and the ability to communicate with other system components and control centers.

Additionally, machine learning algorithms are being integrated into the control systems for LVDT Proportional Valves, allowing for self-optimizing performance based on historical data and real-time feedback. This evolution could lead to even greater efficiencies and reductions in operating costs, as these systems can learn from past operational patterns to predict and respond to future demands.

Further market trends include the push for miniaturization of components, making LVDT Proportional Valves more compact without sacrificing performance. This trend is particularly significant in the aerospace and automotive sectors, where space constraints are a major concern. Manufacturers are exploring new materials and technologies that can withstand extreme conditions while remaining lightweight, contributing to improved fuel efficiency and performance of vehicles and aircraft.

LVDT Proportional Valves stand out from traditional valves due to their precision and versatility. While mechanical valves rely on manual control and basic feedback, LVDT designs offer electronic feedback that is more accurate and can adapt to a variety of applications without significant recalibration. This adaptability is a major factor in their selection over other valve types in critical operations.

Comparatively, servo valves are another option in the domain of precision control. However, while servo valves can also deliver fast response times, they often come with higher costs and complexity due to the need for additional components to meet performance requirements. In contrast, LVDT Proportional Valves are less complex and can often be integrated directly into existing control systems with fewer modifications. This not only streamlines installation and maintenance but also reduces costs in both the short and long term.

Another comparison can be made with piezoelectric valves, which are known for their rapid actuation capabilities. While piezoelectric valves are suitable in specific applications requiring extreme speed, they do not typically provide the same level of sensitivity and stability as LVDT Proportional Valves in a fluctuating environment. This means that for applications requiring consistent and precise control, LVDT Proportional Valves are generally the preferred choice due to their reliable performance over a broader range of conditions.

These valves are crucial due to their ability to maintain precise control over flow and pressure, essential in sectors requiring high levels of accuracy. Their design enables integration within complex systems, ensuring enhanced operational capabilities while reducing the risk of errors and failures that could lead to significant costs.

The LVDT provides electronic signal feedback based on the mechanical position, ensuring consistent and exact control over valve operations. This mechanism allows operators to receive immediate feedback about the valve state, which can inform adjustments and enhance system resilience and performance.

Industries like aerospace, automotive, and industrial automation benefit significantly due to the precise control and durability of these valves. Additionally, sectors such as robotics and renewable energy are beginning to embrace LVDT technology to enhance system efficiency and performance. The versatility of these valves makes them suitable for a wide range of applications beyond traditional uses.

While LVDT Proportional Valves offer numerous advantages, they do come with certain limitations. For example, they may not be suitable for applications requiring ultra-fast valve actuation, where other technologies like servo or piezoelectric valves might perform better. Additionally, LVDT systems may require specific calibration and setup to achieve their optimal performance, which could be a consideration in environments where quickly changing conditions are common.

Choosing the right LVDT Proportional Valve involves considering factors such as the required flow rate, pressure, temperature range, and environmental conditions. It is also essential to evaluate the compatibility of the valve with existing systems and whether it meets the precise control requirements of your application. Consulting with an expert can provide valuable insights to ensure the best match for your specific needs.

As industries evolve towards more automated and precise control systems, the LVDT Proportional Valve remains pivotal in achieving those advancements. Its ability to integrate with modern systems, combined with the advantages of high precision and reliability, underscores its role in the future of industrial operations. With the continuous progress in technology and the growing emphasis on efficiency and sustainability, the demand for LVDT Proportional Valves is expected to rise sharply.

Moreover, as additional industries recognize the benefits of enhanced control and performance, we can anticipate further innovations and applications of this technology. Research and development continue to push the boundaries of what is possible with LVDT systems, paving the way for more sophisticated operations and improved product quality across various sectors.

The future outlook of LVDT Proportional Valves is linked not only to technological advancements but also to the need for industries to adapt to changing market demands and environmental considerations. In summary, the significance of LVDT Proportional Valves in enabling precise control, enhancing efficiency, and fostering innovation will only increase as we move towards a more automated and connected industrial landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!