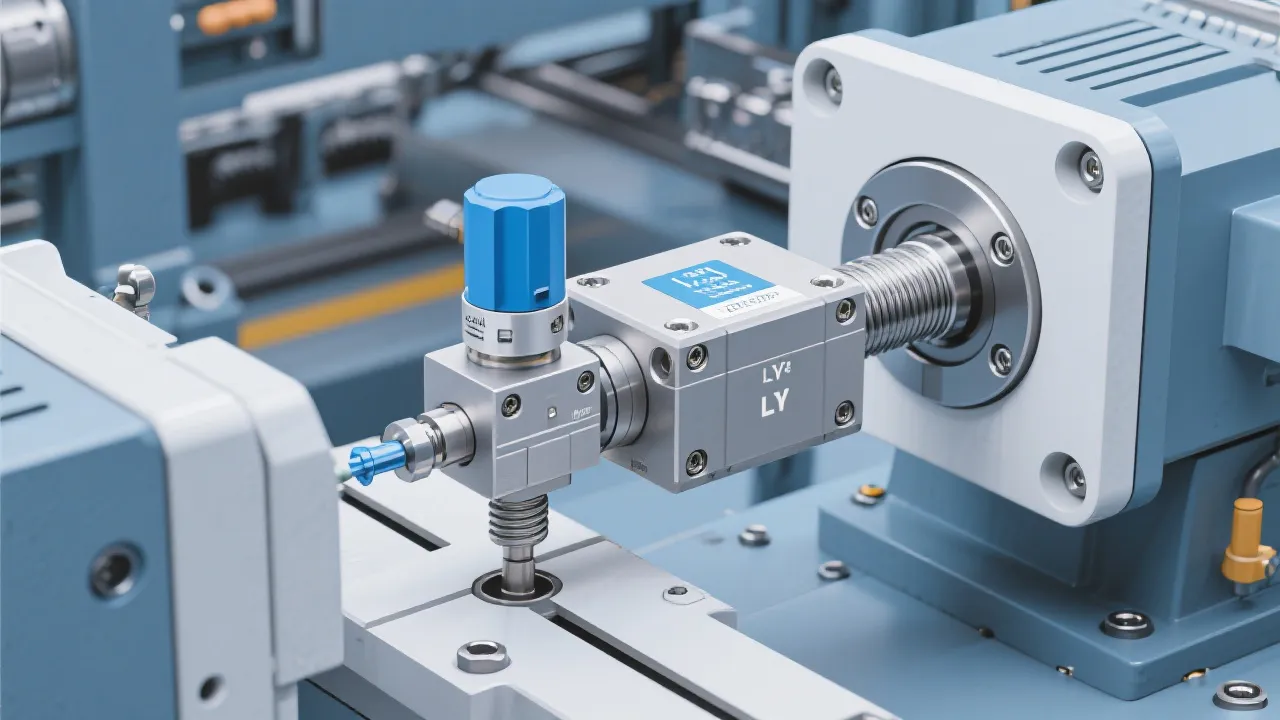

LVDT Proportional Valves play a crucial role in industrial automation by providing precise control over fluid flow. Using Linear Variable Differential Transformers (LVDT), these valves translate mechanical movements into detailed electrical signals, enhancing operational accuracy and efficiency. Their application spans various sectors, including manufacturing, where reliability and precision are paramount.

LVDT Proportional Valves are integral components in modern automation, offering superior control over fluid flow. They are essential in both hydraulic and pneumatic systems due to their capability to provide smooth, precise control that meets the demands of various applications. Utilizing a Linear Variable Differential Transformer (LVDT) to measure the position of the valve spool, these valves convert mechanical movements into proportional electrical signals, allowing for fine control across multiple industries. This technology not only improves efficiency but also enhances the overall performance of the systems they are integrated into. LVDT Proportional Valves are not just about controlling flow; they contribute significantly to the reliability and accuracy of industrial processes.

At the heart of an LVDT proportional valve lies its core technology – the LVDT. This device is a type of transducer used for measuring linear displacement. It operates on the principle of mutual inductance, typically comprising a primary winding and two secondary windings. These components work together to produce an electrical output proportional to the linear position of the valve spool. As the core moves between these windings, it adjusts the induced voltages, which are then interpreted as precise positional data. The relationship between the position of the core and the induced voltages allows for high precision in operations, which is essential for applications like robotics, aerospace, and automotive engineering.

The ability of the LVDT to provide feedback on the valve position makes it an excellent choice for control systems requiring accurate adjustment capabilities. For example, in robotics, the precise control of movement is paramount, and any slight miscalibration could lead to operational inefficiencies or even failures. Therefore, the inherent accuracy of LVDT technology ensures that robotic systems operate within the required parameters, maintaining both safety and functionality.

The use of LVDT Proportional Valves extends across multiple domains, each benefiting from their unique capabilities. In manufacturing, these valves ensure consistent production processes by maintaining stable fluid flow. They are essential in high-precision environments like pharmaceutical manufacturing, where even minor deviations can affect product quality. In such industries, adherence to stringent quality control requirements is non-negotiable, and LVDT valves play a critical role in monitoring and maintaining these standards.

In addition to manufacturing, LVDT Proportional Valves find utility in sectors such as aerospace, where they provide reliable control for critical components. The aerospace industry demands the highest reliability from its components, and LVDT valves deliver by ensuring that even the smallest adjustments in valve position can be monitored and controlled effectively. The redundancy and robustness of these valves are crucial in an industry where failures are not an option.

Moreover, their ability to provide real-time positional feedback enhances the responsiveness and dependability of automated systems. The integration of LVDT technology contributes to operational efficiency and productivity across various sectors. By allowing precise control over fluid dynamics, industries can optimize processes, reduce waste, and improve energy efficiency, leading to substantial cost savings over time.

| Application | Benefits |

|---|---|

| Industrial Automation | Enhances precision and control in complex systems. |

| Aerospace | Provides reliable control for critical components. |

| Robotics | Ensures accurate and responsive movements. |

| Automotive | Improves efficiency in fluid management and safety systems. |

| Pharmaceutical | Maintains product integrity through precise flow management. |

| Food and Beverage | Ensures consistency in production and quality control. |

Integrating LVDT Proportional Valves into existing systems requires careful planning and an understanding of the specific environmental conditions they will face. Factors such as temperature fluctuations, electromagnetic interference, and mechanical vibrations can impact performance significantly. For instance, in environments subject to extreme temperatures, the materials used in LVDT valves must be selected to withstand such conditions without compromising their operational integrity.

In addition, electromagnetic interference (EMI) can affect the accuracy of the signals produced by the LVDT, potentially leading to unsafe operational conditions. Thus, it’s imperative to incorporate shielding and filtering technologies into the design of the surrounding systems to mitigate these effects. Furthermore, attention must be paid to the installation process itself; improper positioning or alignment of the LVDT can lead to degraded performance or even total system failure.

Choosing the right specifications for LVDT Proportional Valves can also significantly influence their efficacy. This includes selecting appropriate voltage ratings, understanding the environmental impact on sensor response, and determining the necessary precision levels for the intended applications. Conducting thorough testing and validation in a controlled environment can help identify potential issues before full-scale deployment.

Proper installation is paramount to the successful integration of LVDT Proportional Valves. Below are some best practices that can help ensure optimal performance:

What industries benefit the most from LVDT Proportional Valves?

These valves are particularly effective in industries requiring high precision and reliability, such as aerospace, pharmaceuticals, automotive, and robotics.

How does an LVDT Proportional Valve improve system accuracy?

By converting mechanical movements into detailed electrical signals, these valves provide accurate feedback for real-time adjustments, enhancing system precision and control.

What are the primary components of an LVDT Proportional Valve?

The primary components include the LVDT transducer, valve spool, and electronic control system, each contributing to the valve's overall functionality. The integration of these components allows for seamless interaction and effective control of fluid dynamics.

What are the common challenges related to LVDT Proportional Valves?

Common challenges include susceptibility to environmental factors such as vibration and EMI, as well as the need for precise installation and calibration to ensure optimal performance.

As industries continue to evolve towards automation and increased reliability, the role of LVDT Proportional Valves will undoubtedly expand. The future of LVDT technology appears promising, particularly with advancements in materials and sensor technologies enhancing their capabilities.

One trend includes the development of smart LVDT technology that integrates IoT capabilities. This allows for real-time data monitoring, predictive maintenance, and remote control functionalities, significantly improving operational efficiency. The implementation of artificial intelligence (AI) algorithms can also lead to more sophisticated control systems that learn and adapt based on operational data, further optimizing performance.

Additionally, advancements in materials science are expected to yield LVDTs that can withstand harsher environments, broadening their applicability across even more sectors. For example, improved resistance to corrosion and temperature extremes can make these valves suitable for more demanding applications, such as deep-sea exploration and harsh chemical environments.

Furthermore, as industries become more focused on sustainability, the demand for energy-efficient technologies will propel innovations in valve design and operation. LVDT Proportional Valves are poised to play an essential role in creating more efficient fluid management systems that reduce waste and energy consumption.

LVDT Proportional Valves represent a pinnacle of sophistication in fluid control systems, blending advanced mechanical design with cutting-edge electronic feedback mechanisms. Their ability to deliver precise control and high reliability makes them essential components across various industries, including aerospace, automotive, pharmaceuticals, and beyond. As industries continue to demand higher accuracy and efficiency, the role of these valves will undoubtedly expand, driving innovation and enhancing productivity.

In summary, the evolution of LVDT Proportional Valves reflects the ongoing advancements in technology aimed at improving efficiency and effectiveness in critical applications. Companies investing in LVDT technology as part of their automation strategies will find themselves well-positioned to meet the challenges of the future, ensuring that they remain competitive in an increasingly automated world.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!