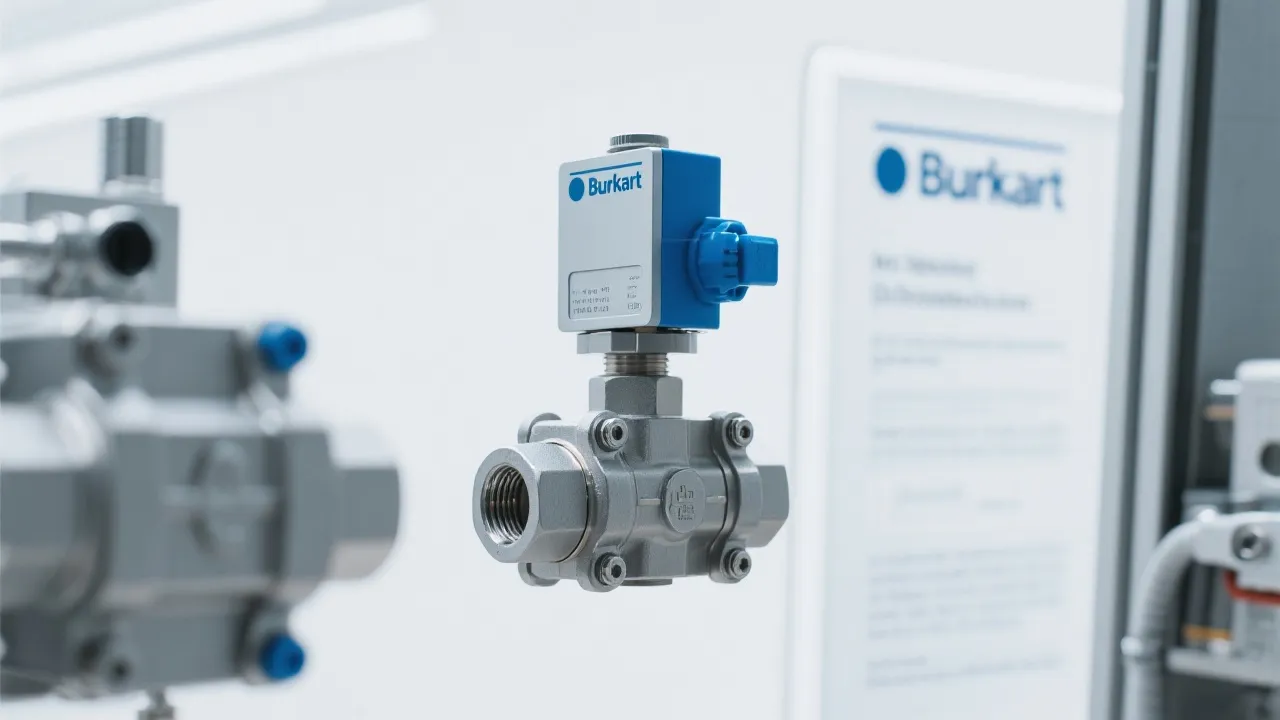

Delving into the functionality and relevance of the Burkert Proportional Valve within various industries, this article sheds light on its significance for fluid control systems. Known for precision and reliability, the Burkert Proportional Valve offers customizable solutions critical for applications demanding consistent flow regulation, making it indispensable for modern engineering tasks.

The Burkert Proportional Valve stands as a cornerstone in fluid control systems, renowned for its ability to modulate flow with precision and reliability. Whether in the realms of industrial automation or sophisticated engineering projects, this valve plays a crucial role by delivering exact control over fluid dynamics. Its versatility and adaptability to various systems render it an invaluable asset in any engineering toolkit. Moreover, as industries move toward greater automation, the Burkert Proportional Valve's significance is increasingly amplified by its ability to integrate seamlessly within smart systems that require advanced control over fluid handling processes.

Burkert Proportional Valves are synonymous with quality and performance. Key features include precise control over fluid flow, high reliability in various environments, and adaptability, making integration seamless across different applications. These valves are engineered to provide consistent performance even under challenging conditions, which makes them ideal for industries such as chemical processing, water treatment, and pharmaceuticals. The design philosophy behind these valves incorporates materials that resist corrosion, temperature fluctuations, and pressure extremes, which enhances their longevity and reduces maintenance costs over time.

Another significant benefit is their ability to provide real-time feedback through integrated sensors, enabling operators to monitor performance metrics continuously. This feature is particularly valuable in automated systems, where precision and immediate response times are critical. Furthermore, the flexibility inherent in Burkert Proportional Valves allows for configurations that can meet specific operational requirements, whether it involves varying flow rates, different fluid types, or customized installation conditions.

Industries around the world recognize the Burkert Proportional Valve for its application in processes requiring meticulous fluid management. These valves are pivotal in situations where exact pressure and flow rate adjustments are necessary. Common industries where they find application include automotive, food and beverage processing, HVAC systems, and pharmaceutical manufacturing. Their design ensures that they can handle the demands of both high and low-pressure systems, offering a broad scope of use that caters to sophisticated industry needs.

In the automotive sector, for instance, the Burkert Proportional Valve is employed in hydraulic systems, where it allows for precise control of fuel, oil, and coolant flow. In food and beverage processing, these valves regulate ingredient flow, ensuring that products meet strict safety and quality standards. HVAC systems utilize these valves for efficient temperature control, modulating refrigerant flow as required for optimal heating and cooling efficiency. Similar patterns of deployment can be observed in the pharmaceutical industry, where precise dosage and flow control are critical to compliance with regulatory standards and ensuring product efficacy.

Moreover, as sustainability becomes an imperative across sectors, the ability of Burkert Proportional Valves to enhance energy efficiency cannot be understated. By ensuring that systems operate only at required capacities, these valves prevent waste and contribute to the reduction of operational costs and environmental impact.

The technical prowess of the Burkert Proportional Valve is evident in its construction and operation parameters. These valves offer various inputs for control, including digital, analog, and CANopen interfaces, allowing flexible integration into different control systems. They come equipped with sensors for feedback on flow and pressure, ensuring a closed-loop control system that waivers little from desired settings. This closed-loop feedback mechanism allows the valve to continuously adjust its position in real time, enhancing the accuracy of flow control.

Typical specifications of the Burkert Proportional Valve include a flow rate range ideal for both low-viscosity and high-viscosity fluids, with many models accommodating pressures up to several bars, thus suitable for various applications. These valves exhibit a significant response time, which is crucial when dealing with dynamic fluid systems that demand rapid adjustments to changing conditions.

In addition to the standard offerings, Burkert also caters to specialty applications, providing valve configurations that include options like explosion-proof constructions for use in hazardous environments, as well as high-temperature variants that can withstand extreme conditions. This level of customization ensures that clients receive solutions tailored to their precise operational demands, further underscoring the versatility of Burkert as a leader in this field.

| Valve Type | Advantages | Common Usage |

|---|---|---|

| Ball Valve | Simple operation, durable | Shut-off applications |

| Burkert Proportional Valve | Precise control, high adaptability | Flow regulation in automated systems |

| Butterfly Valve | Compact size, quick operation | Large volume flow |

| Gate Valve | Minimal pressure loss | On/off control in pipelines |

| Check Valve | Prevents backflow | One-way flow control |

| Solenoid Valve | Rapid actuation, low power consumption | Automated system control |

What makes the Burkert Proportional Valve stand out?

The Burkert Proportional Valve distinguishes itself through its ability to offer exact control over fluid flow and pressure, crucial for high-precision applications. Its robust design and intelligent feedback systems ensure minimal deviation from specified parameters, enhancing overall system reliability.

In which industries is it very commonly used?

This valve is widely used in industries such as chemical processing, water treatment, pharmaceuticals, automotive manufacturing, and food processing due to its reliability and precision. The increasing demand for automation across these sectors further accentuates the need for such sophisticated control devices.

How does it integrate with existing systems?

Integration is seamless due to multiple control interface options, including digital, analog, and CANopen, making it adaptable to various system requirements. This adaptability is critical for modern industrial setups where different protocols and standards must coexist without compromising performance.

Are there any environmental limitations?

The Burkert Proportional Valve is designed to perform reliably under a wide range of conditions, though specific limitations should always be checked against the operating environment. Factors such as temperature extremes, humidity, and media corrosiveness can affect performance, thus necessitating a careful selection process when implementing in specialized environments.

What maintenance practices can extend the lifespan of a Burkert Proportional Valve?

To prolong the lifespan of a Burkert Proportional Valve, regular maintenance practices are paramount. This includes routine inspections to identify wear and tear, cleaning to remove any deposits that may lead to performance issues, and timely recalibration of feedback sensors to ensure ongoing accuracy. Additionally, it is beneficial to consult manufacturer guidelines regarding the replacement of parts such as seals and diaphragms, based on the valve’s operational conditions and frequency of use.

In conclusion, the Burkert Proportional Valve's value is evident in its widespread application across multiple industries requiring precise fluid management. Its ability to provide reliable and adaptable solutions makes it a go-to option for engineers and system designers aiming for optimal fluid control. By embodying technological sophistication, the Burkert Proportional Valve has set the standard for what precision and reliability should look like in modern engineering solutions. Additionally, as industries strive for greater efficiency and sustainability, the role of such advanced control mechanisms is bound to expand further, making the Burkert Proportional Valve an essential component of the future landscape of fluid control technology. Consequently, understanding its capabilities and applications is crucial for any stakeholders involved in fluid management systems.

The field of fluid control is evolving rapidly, driven by advancements in technology and the increasing demand for efficiency and automation. As industries continue to move toward innovative solutions, Burkert Proportional Valves are perfectly positioned to lead this charge. One notable trend is the rise of IoT (Internet of Things) in industrial settings; this paradigm shift allows for enhanced monitoring and control capabilities. With IoT-integrated systems, Burkert valves can be connected to cloud-based platforms that gather real-time data on fluid dynamics. Such integration opens up possibilities for predictive maintenance, where anomalies in performance can be detected and addressed proactively, minimizing downtime and operational disruptions.

Another emerging trend in fluid control is the increasing emphasis on energy efficiency. Many industries are seeking ways to reduce their carbon footprint and optimize energy consumption. Burkert Proportional Valves contribute to this goal by allowing precise control over fluid flows, minimizing excess usage that can lead to energy wastage. Moreover, with developments in smart technologies, these valves are likely to incorporate machine learning algorithms that can adaptively optimize their performance based on usage patterns and environmental conditions.

Burkert is committed to continuous innovation, and this is reflected in its product offerings. Recent advancements include the development of digital valve controls that offer improved functionality and versatility. These digital controls allow for more sophisticated programming, enabling users to tailor the valve's behavior to specific applications. This feature not only enhances control but also provides users with comprehensive diagnostics capabilities, facilitating more straightforward troubleshooting and maintenance.

Additionally, advancements in materials science have led to better valve constructs that withstand extreme conditions while maintaining optimal performance. The use of advanced polymers and composite materials is increasingly common, reducing weight and improving resistance to various media. This change not only enhances longevity but can also lead to cost savings over time as operational efficiency increases.

In a world increasingly reliant on precision in fluid control, the Burkert Proportional Valve stands as a benchmark for excellence. Its features, benefits, and applications reveal its integral role in advancing a diverse range of industries. Looking ahead, as technology continues to reshape fluid management practices, the Burkert Proportional Valve is poised to evolve further, enhancing its capabilities and relevance. Stakeholders and engineers must keep abreast of these developments to harness the full potential of fluid control systems, ensuring they remain at the forefront of innovation in a competitive landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!