This article explores the world of Parker Proportional Valves, highlighting their core functionality and applications in industrial settings. Recognized for their ability to provide variable flow and pressure control, these valves are pivotal in industries requiring precision and efficiency. We delve into their mechanics, benefits, and practical aspects, making a comprehensive guide for industry professionals.

Parker Proportional Valves are essential components in various industrial systems, known for their ability to precisely control the flow and pressure of fluids. These valves are integral in applications that demand high precision and efficiency, spanning industries from manufacturing to aerospace. This article serves as a comprehensive guide to understanding the functionality, benefits, and applications of these versatile components.

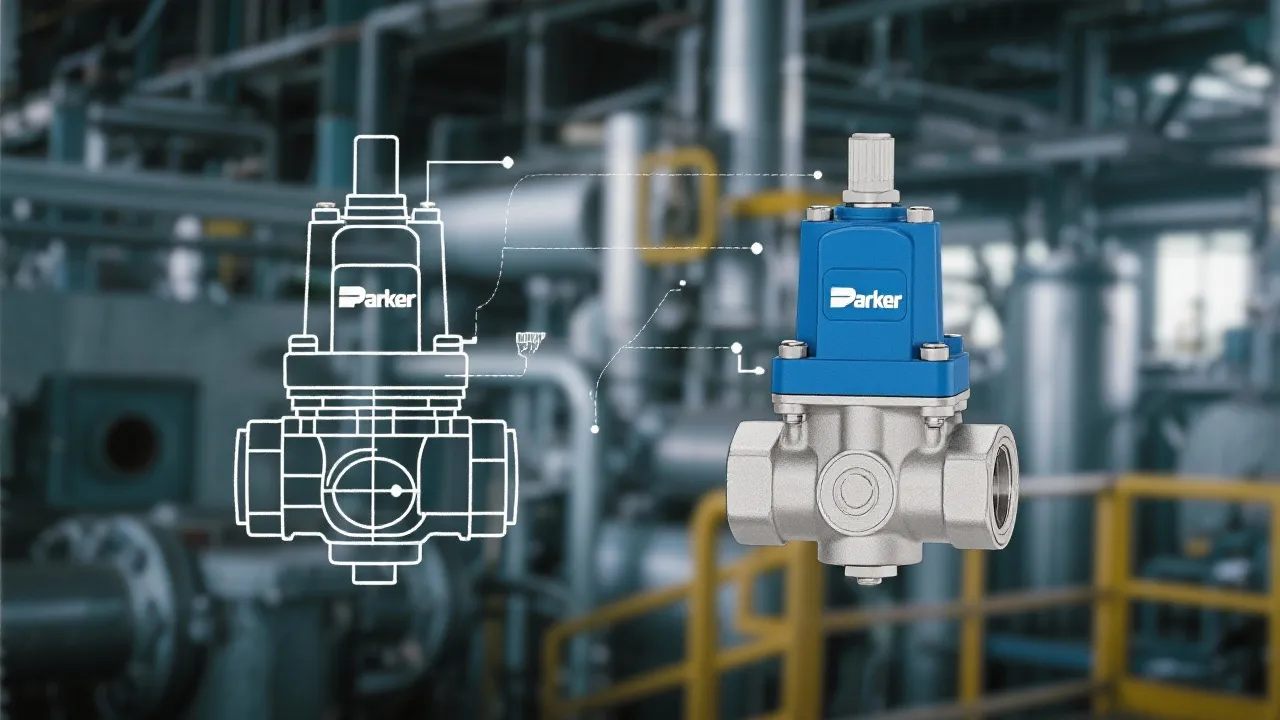

Proportional valves operate by adjusting the flow of a medium, such as hydraulic fluid, in relation to the electrical input signal they receive. This seamless interaction allows for precise control over the speed and movement in systems, which is vital in complex industrial processes. The Parker Proportional Valve achieves this with a spool mechanism directed by a solenoid. The position of the spool, controlled by electronic signals, determines the flow rate, making it an adaptive solution for varying operational demands.

The design of the Parker Proportional Valve incorporates high-quality materials and advanced engineering principles, which contribute to its robustness and reliability. Each valve features a finely tuned spool that regulates flow with high precision; this means that even minor variations in the control signals can lead to significant changes in the hydraulic output. Understanding the mechanical aspects of the valve—such as the materials used in the construction, dimensions, and response time—can further illustrate why these valves are favored in sophisticated applications.

The use of Parker Proportional Valves is prevalent in systems requiring adaptive flow and pressure control. For instance, in injection molding machines, these valves play a crucial role in managing the injection speed and pressure, significantly impacting the quality and precision of the manufactured parts. The capability to finely tune these parameters means that manufacturers can achieve lower defect rates and higher production efficiency.

Similarly, they are invaluable in automotive applications, including braking and engine management systems, where precise fluid control is imperative for safe and efficient operation. In the realm of automotive hydraulics, Parker Proportional Valves help manage brake forces and ensure their application is both rapid and reliable, significantly enhancing driving safety.

Parker Proportional Valves are also critical in the field of robotics and automation. Robotic arms, which perform tasks ranging from assembly to painting, rely on these valves for fine control over actuation sequences. The integration of proportional valves allows for smooth transitions and high repeatability, making them ideal for high-precision tasks that require a significant degree of control.

Another noteworthy application is found in the renewable energy sector, particularly in wind turbines and solar tracking systems. In these scenarios, proportional valves help in controlling pitch adjustments and hydraulic actuators that optimize energy capture, significantly enhancing overall efficiency. Such applications underscore the adaptability of Parker Proportional Valves in emerging technologies that drive sustainability.

To ensure optimal performance, it is essential to consider proper installation and regular maintenance of Parker Proportional Valves. Ensure that the valves are installed in an environment that supports their operation, avoiding extreme temperatures and ensuring proper alignment in the system. Incorrect installation can lead to malfunctions, so utilizing qualified personnel for the installation process is advisable.

Regular checks and calibration are necessary to sustain their precision control capabilities and prolong their service life. Maintenance practices should include:

When choosing a proportional valve, consider factors such as the operating environment, fluid type, system pressure requirements, and desired control accuracy. Additionally, evaluate the required response time and power consumption to match the specific application needs.

By enabling precise flow and pressure control, these valves reduce unnecessary energy consumption and enhance overall system efficiency, saving costs and improving performance. Their ability to modulate flow dynamically based on real-time demand leads to optimized operation and energy use.

Parker Proportional Valves often integrate feedback systems such as position sensors or pressure sensors, which help monitor the valve’s performance. These sensors allow for closed-loop control, enhancing reliability and increasing responsiveness to changing operational conditions.

Yes, Parker constructs its proportional valves to handle various pressure ranges, including high-pressure applications. It is essential to select the appropriate model designed to withstand specific pressures while maintaining performance accuracy.

Parker continues to innovate within the proportional valve sector, developing models with integrated sensors and smart technology. This forward-thinking approach helps address the growing demand for high-performance solutions in increasingly automated and digitally connected environments.

For example, the integration of IoT (Internet of Things) capabilities into Parker Proportional Valves permits real-time monitoring and telemetry data, which can be used to optimize performance and predict maintenance needs. This advancement opens pathways to remote diagnostics and predictive maintenance, which can significantly reduce downtime and enhance operational efficiency.

As industries evolve, the need for enhanced precision, reliability, and energy efficiency only increases, making Parker Proportional Valves a cornerstone of future-ready fluid control solutions. By leveraging advancements in materials science, control algorithms, and sensor technologies, Parker is well-positioned to meet the demands of tomorrow’s industrial environments.

The Parker Proportional Valve is a testament to the significant advancements in fluid control technology, offering unparalleled precision and reliability. As industries evolve, the demand for such intricate components continues to grow, underscoring their critical role in modern industrial applications. The versatility and efficiency of these valves make them indispensable in engineering designs, providing the flexibility required to adapt to a multitude of applications.

Moreover, as businesses face increasing pressure to enhance productivity while minimizing their environmental impact, adopting solutions like Parker Proportional Valves can provide a significant competitive edge. The continuous development of smart technologies in fluid control indicates a promising future for this sector, with ongoing innovations set to redefine standards and capabilities. Ultimately, understanding the functionalities, benefits, and proper maintenance of Parker Proportional Valves positions engineers and businesses for success in an ever-evolving industrial landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!