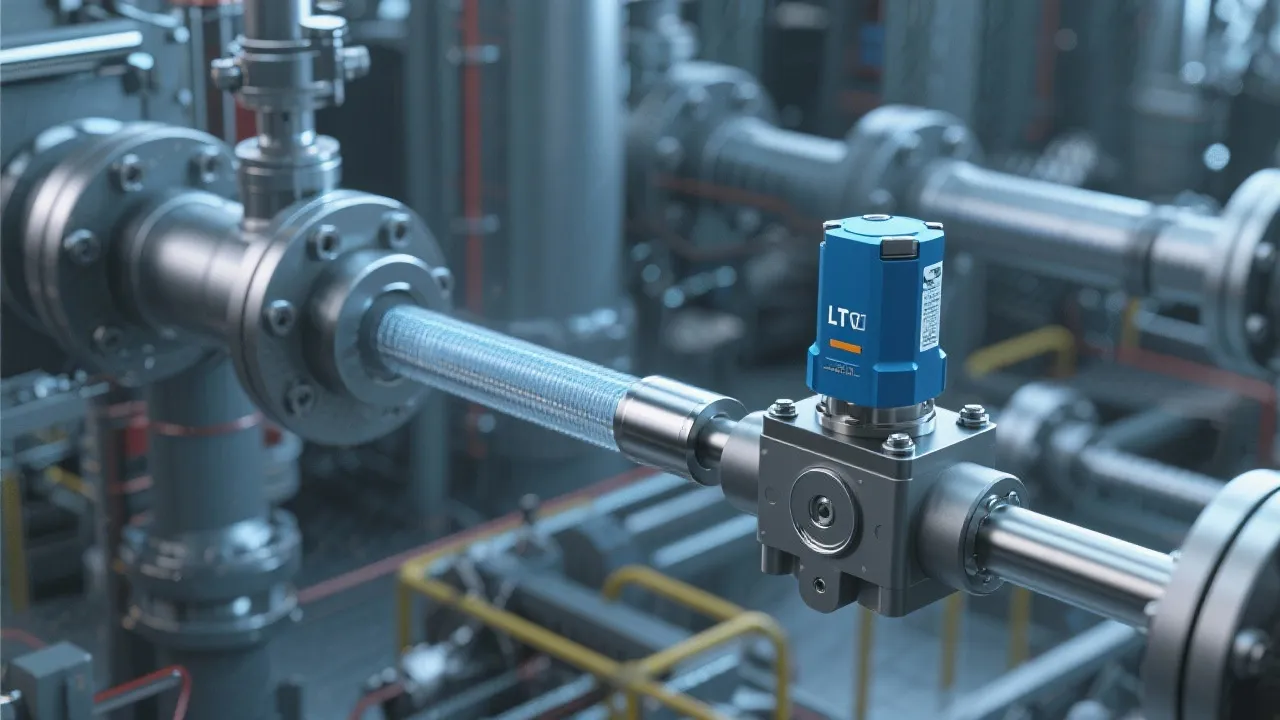

The LVDT Proportional Valve is integral to precise fluid control in various industries. Its design features a Linear Variable Differential Transformer (LVDT) for accurate position feedback, enhancing responsiveness and reliability. Its applications range from aerospace to manufacturing, where exact control of fluid dynamics is essential for system efficiency.

LVDT Proportional Valves play a crucial role in fluid control systems, offering precision and reliability vital for industrial applications. Employing a Linear Variable Differential Transformer (LVDT) mechanism, these valves provide accurate position feedback, which is essential for regulating fluid flow. This article delves into the operational principles, applications, and significance of LVDT Proportional Valves, alongside discussions on their technical characteristics, integration scenarios, maintenance protocols, and case studies that highlight their real-world effectiveness. In understanding these components, businesses can make informed decisions that can lead to overall enhanced efficiency and safety in fluid management operations.

The core functionality of an LVDT Proportional Valve lies in its ability to measure and control valve position with a high degree of precision. An LVDT is a type of position sensor that translates the linear motion of the valve into electrical signals. This conversion enables precise measurement of the valve's position, thereby ensuring the accurate control of fluid flow rates. The proportional control comes from the valve’s ability to adjust fluid flow rate proportionally to the input control signal it receives.

At the heart of the LVDT operation is the transformer itself, which consists of a primary coil and two secondary coils arranged symmetrically around a movable ferromagnetic core. As the core moves due to the valve actuation, the output voltage from the secondary coils changes proportionally to the linear displacement of the core. This system enables not only high accuracy in position measurement but also an inherent robustness against physical disturbances such as vibration, which can be common in industrial settings.

Moreover, the installation of an LVDT Proportional Valve typically includes integration into an automated control system, where PLCs (Programmable Logic Controllers) or DCS (Distributed Control Systems) use the feedback from the LVDT to maintain desired flow rates. The closed-loop control system continuously monitors the flow and adjusts the actuator's position in real-time, ensuring ongoing compliance with operational parameters.

The versatility of LVDT Proportional Valves makes them suitable for a wide range of industries. In the aerospace sector, they are employed for fuel and hydraulic systems control, where precise fluid regulation is imperative. Manufacturing industries use these valves to manage processes that require meticulous fluid control for optimal operation efficiency. Moreover, in chemical processing plants, regulating the flow of hazardous liquids with precision enhances safety and process reliability.

In the automotive industry, LVDT Proportional Valves facilitate the precise control of transmission fluid flow, critical for the smooth operation of automatic transmissions. Similarly, they are employed in HVAC systems for accurate modulation of coolant and refrigerant flows, significantly contributing to energy efficiency in climate control systems. In the medical field, LVDT Proportional Valves are crucial in devices such as infusion pumps where precise volume delivery is essential for patient safety.

Additionally, the oil and gas sector relies on LVDT Proportional Valves for controlling the flow of hydrocarbons through pipelines. Given the high costs and safety concerns associated with leaks or spills in this industry, the continual precision offered by these valves mitigates operational risks and extends the lifespan of the infrastructure involved. Their adaptability to rugged environments and ability to handle various fluid properties make them an ideal choice in facilities that experience fluctuating pressures and flow rates.

While highly effective, LVDT Proportional Valves can face challenges such as calibration and integration within complex systems. Calibration requires careful alignment of the LVDT sensor, which can be time-consuming. However, modern advancements in calibration technology have simplified this process substantially. Automated calibration tools and sophisticated software now offer techniques that allow precise configurations to be established rapidly and easily validated with less manual intervention.

Moreover, integrating these valves into existing systems demands compatibility checks, which can be managed through specialized software solutions. These integration challenges can often be mitigated by consulting with manufacturers for bespoke solutions. Many vendors offer comprehensive software and hardware packages that assist technicians during installation, ultimately leading to smoother operation and faster deployment times.

Another common challenge involves the environmental impact on valve performance. In extremely high-pressure or temperature scenarios, regular LVDT Proportional Valves might encounter operational limits. To combat these limitations, manufacturers have developed versions of these valves specifically engineered for harsh conditions, thereby expanding their applicability in diverse environments while ensuring performance integrity.

Ongoing advancements in materials and coatings also address issues related to corrosion and wear in LVDT Proportional Valves. The use of advanced alloys and protective coatings significantly improves lifespan and resistance, especially in industries like pharmaceuticals, food processing, and petrochemicals, where media properties can be particularly corrosive or abrasive.

| Feature | Description |

|---|---|

| Control Precision | Up to ±0.1% of full range |

| Flow Capacity | Varies from 0.1 to 500 liters/minute |

| Response Time | Typically less than 50 milliseconds |

| Material | Stainless Steel or Aluminum |

| Operating Temperature Range | -40°C to 120°C |

| Power Supply | 12 to 30 VDC |

Regular inspection and calibration are recommended to ensure optimal performance. Preventative maintenance routines can significantly extend the lifespan of these valves, and companies should develop a maintenance schedule that incorporates routine checks and software-based diagnostics.

Yes, many LVDT Proportional Valves are designed to operate in high temperature and high-pressure environments, making them suitable for a variety of industrial applications. Custom options are available to adapt these valves for specific needs, ensuring ultimate reliability.

The LVDT provides continuous feedback on the valve's position, allowing for real-time adjustments and precise control over fluid flow. This operational integrity ensures minimal drift over time and adapts quickly to real-time needs, ensuring that any changes in set points are addressed immediately.

Yes, due to their design and function, LVDT Proportional Valves contribute to energy efficiency within fluid systems by ensuring only the necessary amounts of fluids are used, reducing waste and enhancing overall operational economics.

The main difference lies in the level of precision and feedback. Traditional valves often rely on binary control (open or closed), while LVDT Proportional Valves allow for granular control over flow rates, leading to more efficient and responsive fluid management.

LVDT Proportional Valves are indispensable in applications requiring precise control of fluid dynamics. Their integration into various industries has led to improved efficiency and reliability of operations. The benefits of enhanced accuracy, responsiveness, and flexibility make them crucial components for modern fluid control systems. By understanding the features and advantages of these valves, businesses can better leverage their capabilities to enhance system performance and reliability.

In summary, as industries continue to evolve and demand higher standards of operational excellence, LVDT Proportional Valves represent an essential technology. They not only provide solutions to current challenges in fluid control but also pave the way for innovations that boost performance metrics across numerous sectors. With ongoing advancements in technology and manufacturing processes, the future of LVDT Proportional Valves looks promising, ensuring they remain at the forefront of industrial fluid management system advancements.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!