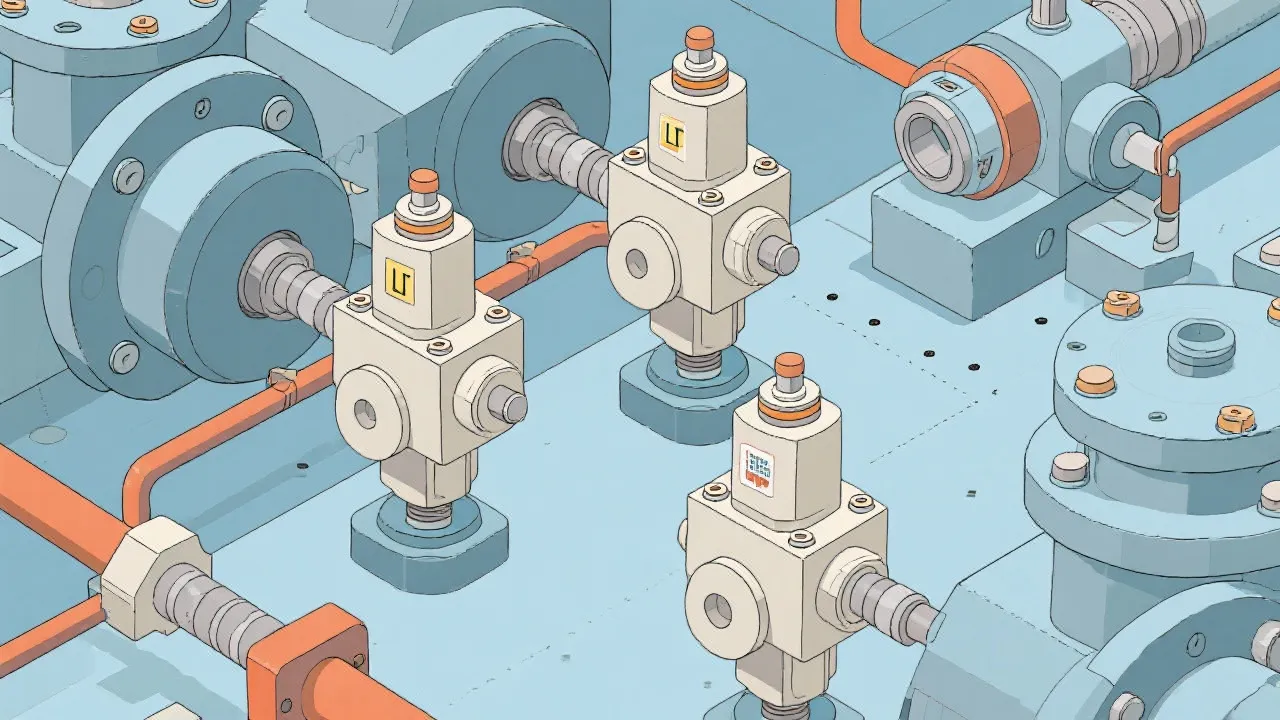

This comprehensive guide explores the intricacies of the LVDT proportional valve, an essential component in precision engineering and industrial automation. LVDT, or Linear Variable Differential Transformer, valves are utilized for their high accuracy in controlling variable flow rates. This article delves into their design, operation, and benefits in modern manufacturing.

The LVDT proportional valve is a critical element in the arsenal of industrial components used to regulate the precise flow of fluids. Known for their high accuracy and reliability, these valves are pivotal in ensuring optimal performance in various applications, including manufacturing, automotive, and aerospace sectors. Understanding the functions and importance of LVDT proportional valves is crucial for professionals in these industries.

An LVDT, or Linear Variable Differential Transformer, proportional valve functions by using an electromagnetic mechanism to control fluid flow proportionally, based on input signals. This actuator-based approach provides seamless regulation over varied flow rates, ensuring that operations maintain efficiency and reliability. The feedback provided by the LVDT enables precise position monitoring, which is indispensable for sophisticated control systems in modern industrial settings.

The design of an LVDT proportional valve is rooted in its core components: the primary coil, two secondary coils, and a movable core. As the core moves within the coils, it alters the voltage in each of the secondary coils. This differential is what provides the continuous feedback to monitor and adjust valve positions accurately. This high level of response and control makes these valves ideal for applications where fine-tuned flow regulation is critical.

The operational mechanism of LVDT proportional valves allows them to function smoothly with minimal wear, making them suitable for high-cycle environments common in several industries. This design minimizes friction and degradation, resulting in a longer lifespan and lower maintenance costs, which adds to their appeal for long-term industrial applications. Additionally, the simplicity involved in their construction allows for easier troubleshooting and repairs, thus streamlining maintenance processes.

To understand how to utilize these valves effectively, one must recognize the importance of the ancillary components that may work in conjunction with the LVDT itself. Control circuits, for instance, play a major role in processing the signals received from the valve and providing appropriate input based on operational demands. The integration of sophisticated algorithms in these control systems can further enhance performance by optimizing flow based on real-time requirements.

LVDT proportional valves are favored in any scenario where precise control of fluid dynamics is needed. This includes applications in hydraulic machinery, automotive suspension systems, and even in the aerospace industry for flight control systems. The common requirement across these areas is the need for reliability and minute accuracy, which these valves can adeptly supply. In hydraulic machinery, for instance, LVDT proportional valves facilitate precise manipulation of hydraulic actuators, leading to improved responsiveness in systems such as cranes and elevators.

In automotive applications, LVDT proportional valves are employed to regulate the tension in systems such as air suspension and adaptive suspension mechanisms. The ability to adjust fluid flow dynamically allows vehicles to adapt to changing road conditions, thus enhancing safety and comfort for passengers. Moreover, in aerospace, LVDT proportional valves contribute to the precision of control surfaces in aircraft, ensuring stability and performance during flight. Such systems demand ultra-high reliability standards, which LVDT valves provide through their robust design and consistent feedback mechanism.

Beyond traditional industrial applications, LVDT proportional valves are increasingly finding roles in renewable energy sectors, such as wind turbine systems where hydraulic actuation is needed for pitch control. This highlights their versatility and increasing relevance in an era where industries strive towards efficiency and sustainability, marrying advanced technology with eco-friendly solutions.

When considering the adoption or replacement of LVDT proportional valves, it is essential to engage with reputable suppliers who offer certified components that meet industrial standards. The integration of these valves should be performed or supervised by skilled technicians to ensure seamless incorporation into existing systems, maximizing their potential benefits. Understanding the specifications specific to your application is crucial, as not all LVDT proportional valves are designed the same way and may not fit every use case. Factors including environmental conditions, fluid types, and system pressure must all be considered during selection.

Moreover, the compatibility of the chosen LVDT valve with existing control systems is another critical consideration. Advanced control systems may offer features such as digital interfaces that allow for easier integration, data collection, and analysis, providing enhanced diagnostic capabilities that can further improve operational insights. Regular training for personnel who will operate and maintain these systems is also essential, as it empowers them to troubleshoot and optimize valve function effectively.

In terms of cost, organizations should weigh the initial price against long-term operational savings provided by reduced maintenance and improved efficiency. Purchasing generalized valves may seem cost-effective upfront but could lead to higher long-term expenses due to inefficiencies or frequent failures. A strategic approach—investing in high-quality, application-specific LVDT proportional valves—can provide significant returns on investment while fostering improved operational reliability.

| Feature | Benefit |

|---|---|

| High Sensitivity | Allows for precise control of fluid flow, crucial for critical applications. |

| Robust Construction | Ensures durability under extreme conditions, reducing maintenance needs. |

| Feedback Mechanism | Provides real-time data for adjustments, enhancing operational efficiency. |

| Low Friction Design | Minimizes wear and enhances longevity for demanding applications. |

| Adaptive Process Control | Improves response to changing operational demands, ensuring optimal fluid flow. |

What types of industries use LVDT proportional valves? Industries such as automotive, aerospace, and manufacturing rely on these valves for precise control of hydraulic and pneumatic systems. In addition to these core sectors, emerging industries such as renewable energy and robotics are increasingly adopting LVDT technology for precise actuator control.

Can LVDT proportional valves be used in both high and low-pressure applications? Yes, their design flexibility allows for usage across a wide range of pressures while maintaining accuracy. Manufacturers often offer a variety of models tailored to specific pressure ranges, so selecting the right type is essential for operational success.

How do I maintain an LVDT proportional valve? Regular inspections for wear and prompt replacement of compromised parts ensure long-lasting performance. It is also advisable to perform routine system checks, taking proactive measures to address minor issues before they evolve into larger problems. Maintenance protocols should include checking electrical connections, ensuring fluid cleanliness, and monitoring overall system performance.

Are there compatibility issues with LVDT proportional valves and existing systems? Compatibility can depend on factors such as the valve's communication protocols and the control systems in place. Confirming specifications and consulting with suppliers during the selection process can help avoid integration issues.

How do temperature and environmental conditions affect LVDT proportional valves? Extreme temperatures and harsh environmental conditions can impact valve performance. Selecting valves designed for specific environmental tolerances can help mitigate these effects and extend the lifecycle of the valve in challenging settings.

The LVDT proportional valve represents a paradigm of precision in fluid control technology. Its application across various sectors underscores its essential role in modern industry. By harnessing their capabilities, industries can achieve unparalleled accuracy and efficiency, thus propelling advances in automation and control systems.

As industrial demands evolve, the importance of fluid control systems, particularly LVDT proportional valves, continues to grow. Industries that embrace this technology not only gain a competitive edge through enhanced operational efficiency but also contribute to a more sustainable future, optimizing resource use without sacrificing performance. The ongoing research and development in this area promise exciting advancements, potentially integrating artificial intelligence for even smarter fluid control solutions. Embracing such innovations will lead to breakthroughs that redefine productivity standards in various sectors.

In the face of changing regulatory landscapes and rising operational costs, the integration of high-quality, efficient components such as the LVDT proportional valve becomes more than just an option; it becomes a necessity. Companies that invest in such technology position themselves as leaders in their industries, setting benchmarks for quality and efficiency that others will strive to match. As the industrial landscape continues to adapt to modern challenges, LVDT proportional valves will undoubtedly remain at the forefront, driving innovation and excellence in fluid control technology.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!