Parker Proportional Valves are advanced devices used in fluid control systems to regulate flow with high precision. Known for their reliability and efficiency, these valves find applications in various industries, including manufacturing and automation. This article delves into the functionality, benefits, and applications, providing a comprehensive look into the technology behind Parker valves.

Parker Proportional Valves, heralded for their versatility and precision, play an essential role in fluid control processes across diverse industrial sectors. These valves are integral components in systems that require meticulous flow management, offering solutions that enhance operational efficiency and product quality. As industries continue to advance technologically, the demand for more precise control mechanisms has increased drastically. In this backdrop, Parker Proportional Valves have emerged as a key player in facilitating complex control processes in various applications.

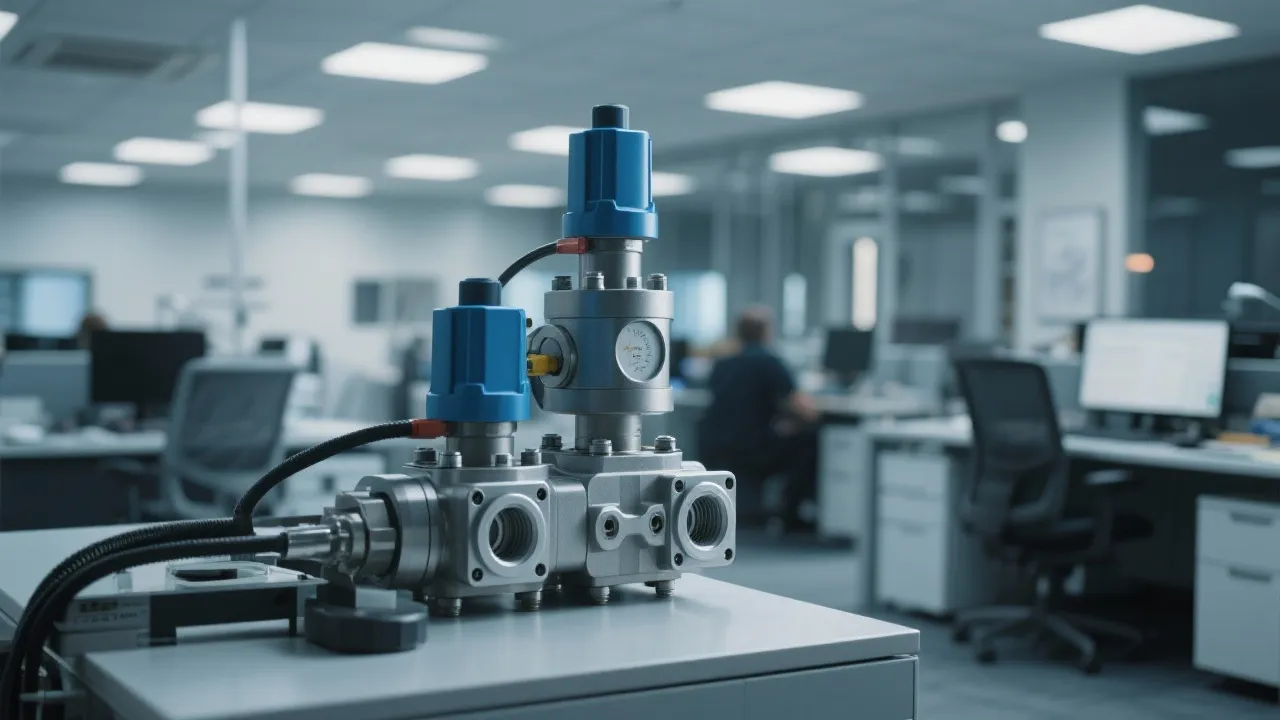

Parker's innovation in creating Proportional Valves encompasses a deep understanding of hydraulic and pneumatic systems. These valves are designed to provide variable control of flow or pressure, making them superior choices for applications requiring infinite positioning capabilities. Distinguished by their robust construction, Parker Proportional Valves are engineered to withstand challenging industrial environments and promising longevity. The technology behind these valves includes advanced electronics and responsive design that allow for dynamic performance adjustments in real-time, which is critical in many high-speed industrial operations.

Moreover, Parker has invested considerable resources into R&D to ensure their proportional valves incorporate the latest advancements in materials and design techniques. This commitment translates not only into improved performance but also energy efficiency, as operators can now achieve desired flow rates with less total energy consumption. Enhanced features such as built-in diagnostics and communication capabilities further add value by allowing for predictive maintenance and process optimization.

Parker Proportional Valves operate by modulating the flow path, dynamically responding to control signals to adjust hydraulic flow and pressure. Their functionality is heavily reliant on the electronic components that regulate their operation, ensuring precise control that is essential in applications where small deviations can lead to significant issues. For example, in robotic applications, precise flow control can enhance positioning accuracy and prevent operational errors.

These valves often integrate advanced feedback systems such as position sensors that communicate the exact positioning to the control system, allowing for continuous adjustments based on changing process demands. Additionally, the proportional valves are designed to minimize response time, improving the overall speed and effectiveness of the systems they are integrated into.

In terms of design, Parker Proportional Valves typically feature multiple ports that allow for extensive connectivity options within fluid systems. This enhances their versatility, allowing them to be used in a wide variety of assemblies where space and configuration differ significantly. Moreover, Parker's extensive option for custom valve configurations means that clients can specify particular flow rates, pressure thresholds, and even response characteristics tailored to their specific application.

The application scope of Parker Proportional Valves is extensive, ranging from the automotive sector to aviation and renewable energy projects. Their use in automation technologies facilitates the precise control necessary for modern industries striving for improved efficiency and reduced environmental impact. For instance, in the automotive industry, these valves can control hydraulic systems in vehicle assembly lines, supporting robots and machinery by ensuring every motion is synchronized and accurate, thereby improving manufacturing efficiency.

In the pharmaceutical industry, where precision is critical, Parker Proportional Valves are utilized in filling systems and drug delivery applications, ensuring that dosing is precise to the milliliter. Similarly, in renewable energy systems — such as wind turbines and solar panel positioning systems — these valves help in actively controlling the angle and positioning in response to environmental conditions, maximizing energy generation.

Moreover, in construction and heavy machinery, the adaptability of Parker Proportional Valves supports functions such as lifting, tilting, and excavating, where precise movement control translates into operational efficiency. Such versatility illustrates how these valves can meet the diverse requirements across sectors while also contributing to the overall safety and performance of machines and processes.

| Attribute | Parker Proportional Valve | Competitor Valves |

|---|---|---|

| Precision | High precision in flow control | Varies, often less precise |

| Durability | Designed for extreme conditions | May have limitations under stress |

| Application Range | Broad and versatile | Often industry-specific |

| Energy Efficiency | Optimized for reduced energy consumption | Less focus on energy efficiency |

| Smart Features | Integrated diagnostics and communication | Limited or no integration |

| Customization Options | Highly customizable to specific needs | Typically more standardized |

Examples of Parker Proportional Valves in real-world applications highlight their versatility and effectiveness across various sectors. For instance, in the manufacturing sector, a leading automotive company integrated Parker Proportional Valves into their assembly line for controlling clamp pressure in robotic welding stations. The ability to adjust pressure dynamically resulted in improved weld quality, reduced rework, and minimized material waste.

In the aerospace industry, Parker valves are used within landing gear systems, providing precise control over hydraulic pressure needed during both deployment and retraction of the gear. This critical application demonstrates how safety and reliability are paramount in aerospace and how Parker's advanced engineering meets those demands.

Another notable case is within agricultural machinery, where Parker Proportional Valves facilitate better control of hydraulic systems in modern tractors. These valves enable variable rate control for seeders and sprayers, allowing farmers to optimize resource use and minimize environmental impact while maximizing productivity—a clear example of technology improving operational efficiency in agriculture.

Parker Proportional Valves offer advanced flow and pressure control through variable positioning, unlike standard valves that typically provide binary on/off control. This functionality allows for more nuanced and sensitive control of hydraulic systems, which is particularly critical in applications requiring precise movements and adjustments.

They are prevalent in automotive, manufacturing, pharmaceuticals, and energy sectors for precise modulation of fluid flow. It is not uncommon to find them integrated into systems that require meticulous regulation, such as pneumatic controls, hydraulic actuation, and in various automation technologies.

Consider factors such as system pressure requirements, fluid type, temperature conditions, and required precision of control. Consulting with a Parker representative can also aid in making informed decisions, ensuring that you choose the best valve tailored to your specific application needs.

In the event of a malfunction, the first step is to review the diagnostic information if available. Parker valves equipped with integrated diagnostics can provide valuable insights. If problems persist, consult with Parker's technical support team or refer to the installation and maintenance manual for troubleshooting guidance.

In conclusion, Parker Proportional Valves stand out as a crucial component in enhancing industrial fluid control. Their reliability, precision, and adaptability make them suitable for complex, demanding applications, solidifying Parker's reputation as a leader in engineering fluid control solutions. As industries continue to evolve and prioritize efficiency, the role of Parker Proportional Valves will only become more central, driving innovative applications and systems integration across diverse sectors.

As technology continues to advance, the future of Parker Proportional Valves appears bright with numerous opportunities for innovation. Industry experts predict a growing need for more intelligent systems, where valves are not just passive components but integral parts of actively monitored and controlled systems. This trend is reflective of the broader move towards Industry 4.0 and smart manufacturing, where interconnected systems leverage real-time data to optimize performance.

One notable trend is the integration of IoT technology within valve systems. By incorporating sensors and network connectivity, Parker Proportional Valves can provide continuous feedback and contribute to predictive maintenance strategies, enabling users to schedule maintenance before failures occur. Such proactive measures are likely to minimize operational disruptions and extend the lifespan of both the valves and the systems in which they operate.

Furthermore, sustainability is increasingly influencing product development. As industries seek to reduce their ecological footprint, valves that maximize energy efficiency and minimize fluid loss will become more sought after. Innovations may include advanced materials designed to reduce wear and tear or valve designs that optimize flow characteristics while reducing energy consumption.

Additionally, miniaturization could lead to the development of compact valve solutions without compromising performance. This would enable more flexible designs in space-constrained applications, opening up new possibilities in sectors such as robotics and mobile machinery.

Lastly, the refining of manufacturing processes, including additive manufacturing, is expected to enhance valve design and production. By leveraging advanced manufacturing techniques, Parker could optimize designs for better performance characteristics while also reducing production costs.

In summary, the future of Parker Proportional Valves is poised for significant growth driven by advancements in technology, increasing focus on sustainability, and evolving industrial demands. As these factors converge, they will shape the next generation of fluid control solutions that not only meet but exceed current market expectations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!