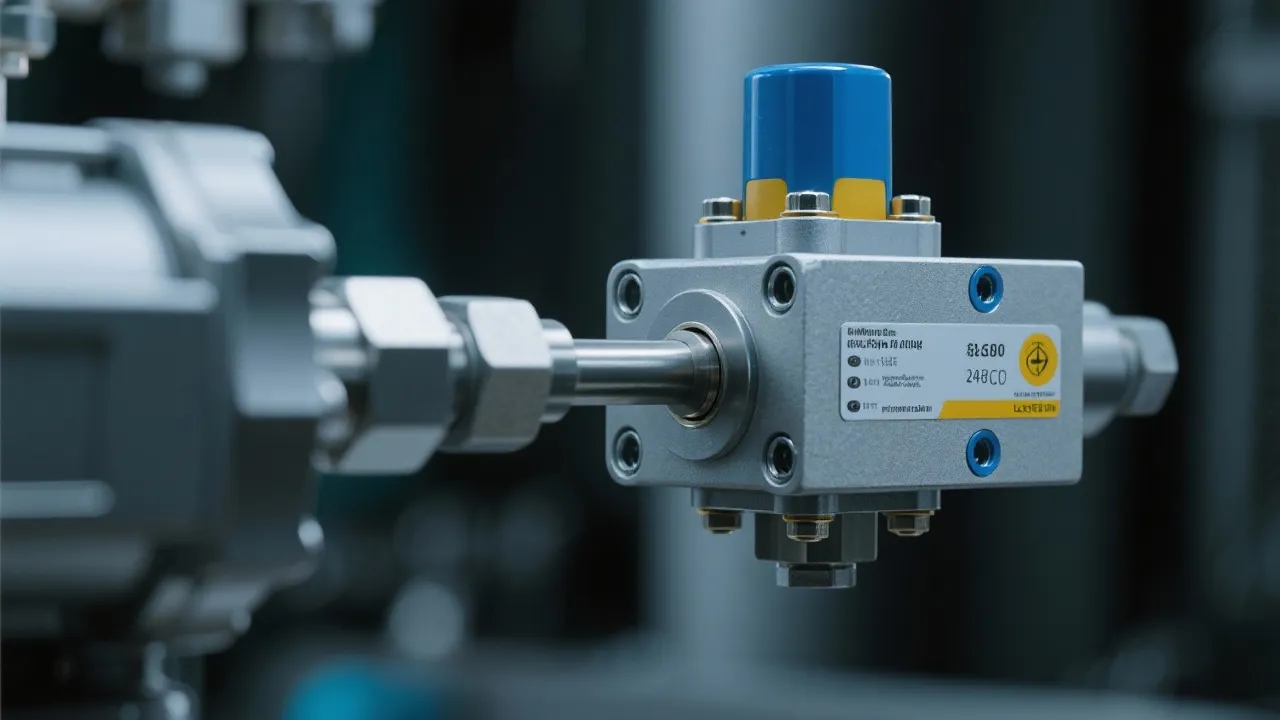

The Burkert Proportional Valve stands at the forefront of fluid control technology, vital across various industries for its precision and efficiency. Proportional valves play a crucial role in managing the flow rate and pressure of various fluids. As industrial automation progresses, these components are increasingly integral to achieving optimized performance and energy savings in complex process systems.

Proportional valves, such as the Burkert Proportional Valve, are indispensable in modern fluid control systems. These devices allow for precise regulation of fluid flow, which is crucial for maintaining efficiency and safety in a wide range of industrial operations. Unlike traditional on/off valves, proportional valves offer a variable flow rate, providing greater accuracy and control. This flexibility helps to optimize operations, reduce wastage, and improve the quality of processes across various industries.

In recent years, the demand for precision in industrial applications has significantly increased, prompting manufacturers to innovate and integrate more sophisticated technologies into their processes. The growing complexity of applications, especially in sectors such as pharmaceuticals, food processing, and chemical manufacturing, demands that fluid control systems be not only responsive but also reliable over extended periods and under varying conditions. This highlights the vital role proportional valves play in ensuring operational consistency and safety.

The Burkert Proportional Valve is renowned for its advanced design, reliability, and ability to function effectively under various conditions. These valves are commonly used in sectors such as pharmaceuticals, food processing, and chemical production, where maintaining exact flow rates and pressures is essential for product quality and safety. The valve's adaptability and precision make it an optimal choice for processes requiring meticulous control over fluid dynamics.

In the pharmaceutical industry, for instance, the need for stringent control over fluid delivery is paramount, as even minor deviations can lead to changes in a product's efficacy. Burkert valves enable the automatic adjustment of fluid flow based on real-time system requirements, ensuring that drugs are consistently manufactured according to stringent standards. In the food processing sector, maintaining exact temperatures and fluid flow is critical not only for product quality but also for compliance with health regulations. The precision control offered by these valves helps in achieving such standards.

The development of the Burkert Proportional Valve illustrates significant technological advancements in valve engineering. These include enhancements in actuator design, improved response times, and integration with digital controls for seamless automation. The introduction of smart technologies has also allowed these valves to communicate with other systems, enabling real-time monitoring and feedback.

One of the most significant innovations is the integration of electronic control systems, which allow users to tailor valves to specific applications more precisely. This can involve adjusting response curves, enabling different operating modes, or configuring the valve to work optimally with variable fluid characteristics. Additionally, the use of high-grade materials ensures durability and compatibility with different fluid types, ranging from aggressive chemicals to pure water. These advancements not only enhance performance but also contribute to lower operational costs by minimizing maintenance needs and improving energy efficiency.

| Feature | Burkert Proportional Valve | Conventional Proportional Valve |

|---|---|---|

| Control Accuracy | High precision with minimal hysteresis | Moderate accuracy with higher variability |

| Material Durability | Composed of corrosion-resistant alloys | Standard metallic compositions |

| Integration with Systems | Seamless integration with digital and analog systems | Limited digital compatibility |

| Response Time | Rapid response with high-frequency switching capabilities | Slower response speeds, often unsuitable for dynamic applications |

| Maintenance Needs | Lower maintenance due to superior engineering | Higher maintenance requirements, potentially leading to increased costs |

| Energy Efficiency | Designed for low energy consumption | Higher energy usage, particularly under varying load conditions |

Implementing the Burkert Proportional Valve requires careful consideration of the entire system's parameters, including flow characteristics, pressure requirements, and the type of fluids handled. Adequate knowledge of the system design is essential to ensure that valves are selected appropriately for the expected pressures and fluid types. This initial evaluation will help in choosing the right size and type, ultimately affecting the performance of the entire system.

Proper calibration and regular maintenance are essential to ensure optimal performance and longevity. It is advisable to incorporate routine checks into operational schedules. Regular testing against flow rates, pressure readings, and response behaviors should be established as standard practices. Additionally, leveraging these valves in conjunction with sophisticated automation systems can lead to significant improvements in process efficiency and reduced operational costs. Integration with computerized systems allows for real-time adjustments and data logging, helping operators to fine-tune processes and minimize errors.

Another critical aspect of implementation is staff training. Employees need to understand how to operate and troubleshoot these valves effectively. Comprehensive training programs should be initiated that cover basic operation, maintenance procedures, and the importance of these components in the context of overall system performance. Engaging with vendors for technical support and training can enhance in-house capabilities.

Q1: What industries benefit greatly from the Burkert Proportional Valve?

A1: Industries like pharmaceuticals, food and beverage, and chemical manufacturing benefit greatly from the precision and reliability of Burkert Proportional Valves. In industries where safety and quality are paramount, such as medical and food applications, the use of accurate fluid control technologies is essential for maintaining compliance with industry standards.

Q2: How does a proportional valve differ from a traditional valve?

A2: Proportional valves offer variable control over fluid flow, as opposed to traditional valves which are typically in an on/off state. This means that proportional valves can adjust flow based on input signals, allowing for fine-tuned control of processes, whereas traditional valves can only halt or allow flow, which may not be suitable for applications requiring precise fluid management.

Q3: Are Burkert Proportional Valves compatible with all fluid types?

A3: These valves are designed using durable materials to handle a range of fluids, including aggressive chemicals and pure water, making them highly versatile. However, it is crucial to verify compatibility with specific chemical and physical properties of the fluids being handled, as improper material selection may lead to premature failure.

Q4: Can Burkert Proportional Valves be integrated into existing systems?

A4: Yes, Burkert Proportional Valves are designed for seamless integration with both existing digital and analog systems. This flexibility allows companies to retrofit their current setups with advanced valve technology, enhancing process efficiency without the need for complete overhauls.

Q5: What maintenance practices are recommended for Burkert Proportional Valves?

A5: Recommended maintenance practices include regular inspections, functionality tests, and verification of calibration settings. It is also essential to flush the valve regularly to prevent the buildup of particles that could affect performance. Furthermore, leverage manufacturer guidelines for specific maintenance protocols based on the application and frequency of use.

In conclusion, the Burkert Proportional Valve represents a significant leap forward in valve technology, offering unparalleled precision and adaptability for modern industrial applications. As industries strive for more efficient and reliable systems, the integration of such advanced components will be critical in meeting future challenges and achieving optimum performance. With the advancement of smart technologies, Burkert Proportional Valves not only meet the current demands of fluid management but also prepare companies for future innovations across diverse sectors, ensuring they remain competitive in a fast-evolving marketplace.

The field of proportional valve technology continues to evolve, with several emerging trends shaping its future. As industries lean increasingly towards automation and Industry 4.0, proportional valves are being designed to incorporate smart features such as IoT connectivity. This allows for enhanced data analysis and predictive maintenance capabilities, ultimately leading to reduced downtime and improved operational efficiency.

Next-generation proportional valves are likely to feature more sophisticated sensors and control algorithms that allow for adaptive behavior based on changing process conditions. For instance, a valve could learn from historical data to optimize its performance autonomously over time, adjusting flow rates and pressures in real-time to maintain optimal system performance.

Moreover, the push for sustainability within the manufacturing sector is prompting research into more environmentally friendly materials and designs. Future proportional valves may utilize biodegradable components or be designed for easier recycling at the end of their life cycle. These advances not only fulfill regulatory requirements but also align with corporate social responsibilities and consumer expectations for sustainability.

Additionally, as digital twins and simulation technologies become more prevalent, they will be integrated into the design and testing phases of proportional valves. This can lead to even greater optimization, as engineers can model the performance of valves under varying conditions and tweak designs before actual production. The end result will be valves that are not only more efficient but also tailored specifically to the nuances of their intended applications.

Choosing the right proportional valve for any application is paramount to ensuring success. Key considerations include the type of fluid, the required flow rate, compatibility with existing systems, and anticipated operating conditions. Companies must also evaluate their specific process requirements, such as the need for fast response times or high precision in flow control. Inappropriate valve selection can lead to significant operational inefficiencies and increased costs, which makes it essential for engineers and procurement professionals to work closely together during the selection process.

A well-selected proportional valve can enhance not only the efficiency of the fluid delivery system but also the safety and quality of the end product. For instance, improper flow rates in a pharmaceutical application could lead to incorrect dosages, jeopardizing patient safety. Hence, the stakes are high for making informed decisions, especially in applications where precision is non-negotiable.

It is also important to collaborate with reputable suppliers who provide comprehensive support, including technical advice and assistance in the integration of these valves into existing systems. A supplier that offers robust after-sales support can help troubleshoot any problems that arise during installation and operation, ensuring that the system remains efficient and effective over time.

In summary, as industries continue to evolve, the significance and application of proportional valves like those manufactured by Burkert will only grow. The careful consideration of valve selection and integration stands as a fundamental component in driving forward the efficiency, safety, and sustainability of industrial processes across a vast range of sectors.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!