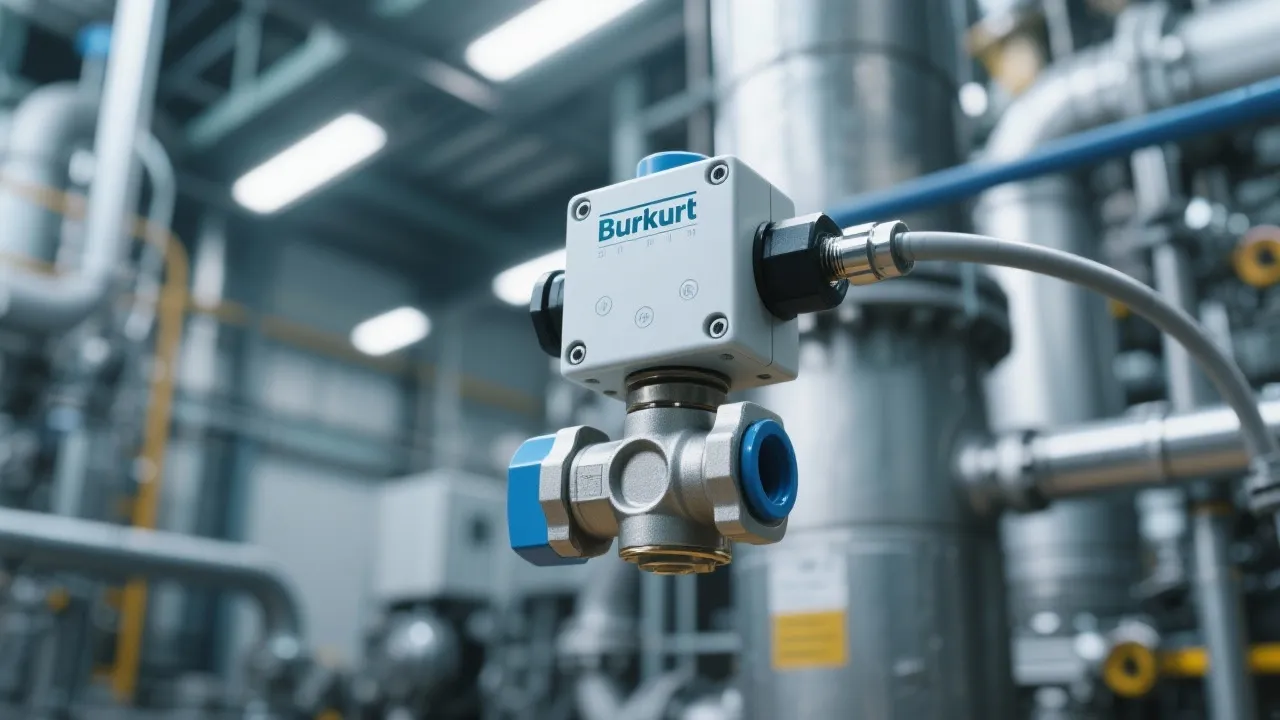

This comprehensive guide explores the integral role of Burkert Proportional Valves in industrial automation, showcasing their efficiency and control capabilities. These valves, known for precision modulation of fluid flow and pressure, are critical in diverse industries, enhancing system performance and reliability while reducing energy consumption and maintenance costs.

Burkert Proportional Valves are a pivotal element in fluid management systems, providing precise control over the flow rate of liquids and gases. These valves adjust flow rates based on the input signal, making them indispensable in environments where exact fluid dynamics are critical, such as in chemical processing, pharmaceuticals, and food production. The ability to modulate flow in response to system demands not only enhances efficiency but also contributes to improved system safety and product quality.

Unlike standard on/off valves, Burkert Proportional Valves incorporate advanced actuation technology. This allows them to deliver variable output flow corresponding to the input signal, which can be modulated through electronic controllers. These controllers, in turn, receive input from sensors measuring flow, pressure, or temperature, enabling a closed-loop control system. Such dynamically adjusting systems ensure optimal process conditions, enhancing both performance and efficiency. The sophisticated design includes features like an integrated feedback loop, which enables real-time adjustments. This means that even with fluctuations in demand or operating conditions, the valve can swiftly adjust to maintain the desired flow rate.

Further, the proportional control mechanism allows these valves to operate more smoothly compared to their conventional counterparts. Instead of the abrupt changes associated with on/off valves, Burkert Proportional Valves can adjust gradually, minimizing pressure surges and enhancing the overall stability of the system. This gradual response is essential in sensitive applications, where abrupt changes might not only destabilize processes but also lead to defects in product quality.

The versatility of Burkert Proportional Valves allows them to be employed across various industries:

| Feature | Burkert Proportional Valves | Conventional Valves |

|---|---|---|

| Control Type | Variable proportional control | Binary on/off control |

| Efficiency | Higher, due to precise modulation leading to less energy waste | Lower, wasteful due to fixed open/close positions |

| Maintenance Frequency | Less frequent due to robust construction and lower wear | More frequent maintenance due to wear and tear associated with abrupt operation |

| Response Time | Fast and adjustable for specific needs | Delayed due to inherent switch nature |

| Cost | Higher initial cost, but lower lifetime operation costs | Lower initial cost; however, higher operational costs due to inefficiency |

Installing a Burkert Proportional Valve requires careful consideration of system requirements, ensuring compatibility with existing infrastructure. It is recommended to engage a certified technician for installation. Regular maintenance involves inspecting the valve for any signs of wear and verifying calibration, which should be done annually to sustain optimal performance.

For installation, proper electrical and hydraulic connections must be established. Ensuring that the valves are correctly oriented is crucial; misalignment can lead to inefficiencies and potential permanent damage to the valve. Furthermore, maintaining clean lines devoid of debris or particulates is essential, as contaminants can affect performance and longevity. Utilizing filters upstream can help manage this risk effectively.

Regular maintenance checks should include testing the control system functionality, calibrating flow rates, and assessing the health of associated components such as sensors and controllers. Professionals often recommend a preventive maintenance schedule where common wear factors like seals and actuators are inspected and replaced as part of regular service protocols, thus extending the service life of the valves.

Q: Are Burkert Proportional Valves suitable for corrosive environments?

A: Yes, specific models are designed with corrosion-resistant materials suitable for harsh environments. Various materials, such as stainless steel and specialized alloys, can be selected based on the chemical compatibility with processed fluids.

Q: Can these valves be integrated with existing control systems?

A: They are highly adaptable, often compatible with various industry-standard control systems, including PID controllers, PLCs, and SCADA systems, making implementation straightforward and minimizing downtime during upgrades.

Q: What is the longevity of a Burkert Proportional Valve?

A: With proper maintenance, these valves are engineered to last several years, often exceeding 10 years, offering reliable service over extensive periods. Usage conditions and maintenance habits will heavily influence this lifespan.

Q: How do I choose the correct Burkert Proportional Valve for my application?

A: Selection should include factors such as the fluid's characteristics (viscosity, temperature, corrosiveness), required flow rates, the control method, and whether you require a digital or analog signal for operation. Consulting with a Burkert representative or a knowledgeable technician can help narrow down the options based on your specific needs.

Burkert Proportional Valves, through their precision and reliability, play an instrumental role in modern industry applications. Their ability to finely tune process conditions ensures not only optimized system performance but also significant cost savings over time, making them a worthy investment for businesses striving for efficiency and quality. The advanced technology, extensive application versatility, and reliability have made them a preferred choice across various sectors, compelling many organizations to upgrade from conventional valves to proportional solutions.

As industries continue to evolve towards automation and enhanced precision, Burkert Proportional Valves will undoubtedly remain at the forefront, providing both the adaptability and control necessary in today’s advanced manufacturing environments. Their contribution to improved monitoring and control capabilities serves as a testimony to the importance of integrating innovative technologies in fluid management systems.

The future of Burkert Proportional Valves and similar technologies is geared towards further enhancements in automation and connectivity. With the rise of Industry 4.0, the demand for smarter and more interconnected systems is growing. Proportional valves are expected to incorporate advanced features such as IoT capabilities, allowing for remote monitoring and control.

Additionally, algorithms driven by artificial intelligence and machine learning are likely to optimize performance in real-time, learning from historical data to predict system needs more accurately and adjusting responses dynamically. Moreover, there is a trend towards more environmentally friendly solutions as industries focus on sustainability. This includes the development of valves that consume less energy while maintaining high efficiency and performance.

As sustainability becomes paramount, manufacturers are investing in research aimed at creating materials that reduce waste and improve recyclability. This aligns with global trends towards minimizing environmental impact while meeting stringent operational requirements.

Furthermore, with the expanding applications of proportional valves in sectors such as renewable energy, biomedical fields, and autonomous vehicles, ongoing innovations will likely emerge. For instance, in the renewable energy sector, valves that can manage the variable flow of resources like solar or wind energy will become increasingly necessary. Similarly, the biomedical field may demand higher precision in fluid delivery systems, such as those used in advanced medical devices.

In conclusion, the continuous evolution of Burkert Proportional Valves suggests they will remain crucial for any advancement in fluid dynamics technologies. Whether through the development of more accurate sensors, more robust materials, or smarter algorithms, the future of proportional valves holds significant promise for enhancing efficiency, sustainability, and operational excellence across numerous industries.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!