Eaton Proportional Valves are key components in hydraulics, providing precise control over fluid flow and pressure in various industrial applications. These valves ensure high-performance in complex systems, enhancing efficiency and reliability. Suitable for diverse sectors, Eaton's technology supports everything from manufacturing to aerospace, allowing for advanced fluid management solutions.

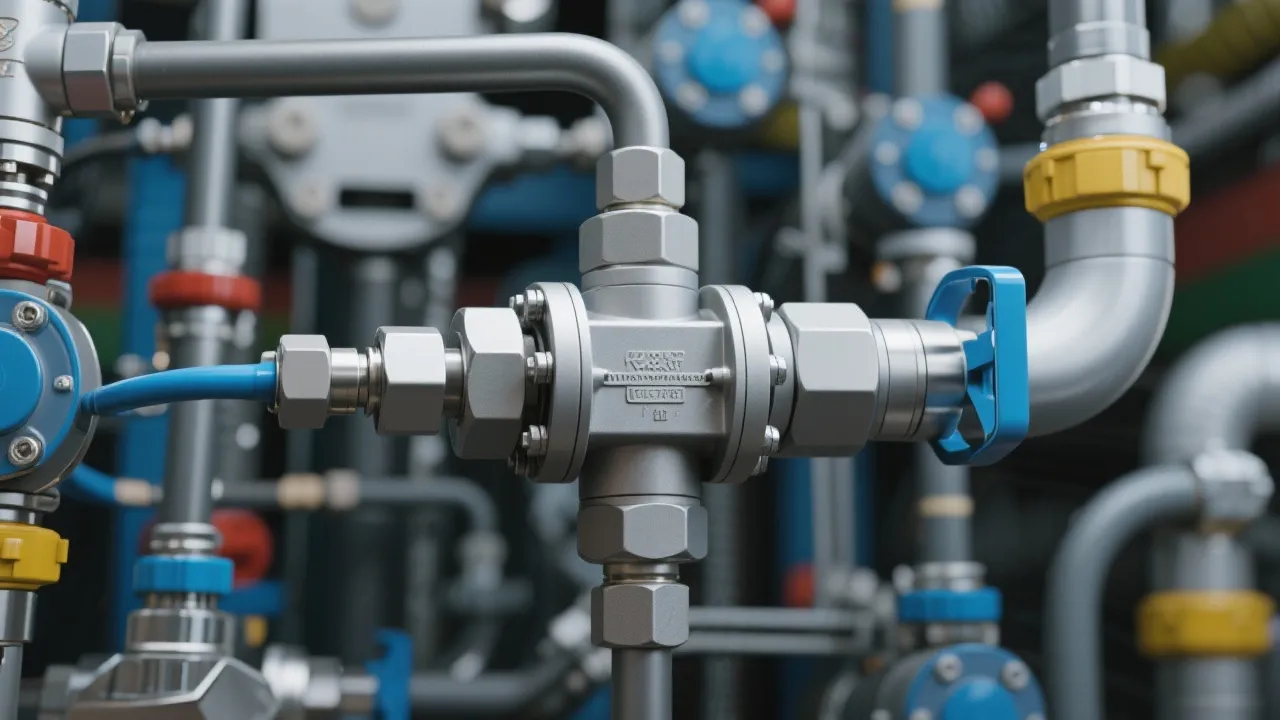

In the advanced world of hydraulic systems, Eaton Proportional Valves occupy a pivotal role. These devices are not just about controlling fluid flow; they epitomize precision, efficiency, and performance, crucial for many industrial applications across diverse fields. By converting electrical signals into fluid dynamic actions, Eaton Proportional Valves enable sensitive adjustments that drive the efficiency and productivity of hydraulic systems. Their development has been influenced by the growing demand for precise motion control in various sectors, propelling innovation and engineering excellence in fluid dynamics technologies.

Eaton Proportional Valves stand out due to their unique features, which include precise flow control, enhanced reliability, and durable construction. These valves are designed to operate under challenging conditions, maintaining performance and accuracy over time. Their capacity to handle varying degrees of pressure and flow makes them indispensable in industries that require meticulous fluid regulation, such as automotive manufacturing, aviation, and heavy equipment operations.

Beyond their fundamental features, Eaton Valves also incorporate cutting-edge technology that allows for smarter integration within hydraulic systems. Innovations in sensor technology enhance their operational capabilities, contributing to the trend of automation in industrial setups. Consequently, users experience not only performance optimization but also reduced energy consumption, translating into more sustainable operational practices.

| Feature | Benefit |

|---|---|

| Precise Flow Control | Allows for fine-tuned adjustments in hydraulic systems, leading to increased system efficiency. |

| Durable Construction | Ensures longevity and consistent performance even in harsh environments. |

| Enhanced Reliability | Minimizes downtime and maintenance needs, providing more operational uptime and productivity. |

| Smart Integration | Facilitates integration with modern automation systems, allowing for remote monitoring and control. |

| Energy Efficiency | Reduces operational costs and supports sustainable practices by minimizing unnecessary energy consumption. |

| Customizable Configurations | Offers a range of options to meet specific application needs, ensuring optimal functionality. |

The versatility of Eaton Proportional Valves is evident in their wide-ranging applications. They are prevalent in manufacturing settings where precision is critical, such as CNC machinery and robotic automation. The demand for accuracy in these environments cannot be overstated; any deviation can lead to significant operational losses. Moreover, these valves play an essential role in the automation of processes, allowing for efficient mass production and consistent product quality.

In addition to manufacturing, Eaton Proportional Valves serve in agricultural equipment, enabling high-performance machinery to operate at optimum levels. For instance, in precision farming, they allow for varying fluid delivery rates that match the specific needs of different crops, consequently improving yield and resource management. Similarly, in mining machinery, these valves assist in controlling heavy equipment operations with a focus on safety and efficiency, which are critical in high-stakes environments.

Furthermore, in the aerospace industry, these valves contribute to the fine control needed for various flight systems. The stringent regulations governing aircraft systems mean that reliability and performance are paramount. Eaton Proportional Valves provide these qualities, ensuring that hydraulic lifts, landing gear systems, and other applications operate flawlessly, thus enhancing both safety and performance standards in aviation.

When considering valves of similar capabilities, Eaton's products are frequently compared with those from Bosch Rexroth and Parker Hannifin. Each brand has its strengths, but Eaton valves often gain preference due to competitive pricing while maintaining high functional standards and efficiency. Furthermore, the after-sales service and support from Eaton provide additional value, ensuring systems remain operational with minimal setbacks.

The comparison extends beyond just price; it also encompasses innovative features. Bosch Rexroth may offer state-of-the-art electronic control systems, while Parker Hannifin is often lauded for its broad range of product offerings. However, Eaton's focus on modular designs allows for simplified expansion and upgrades within existing systems, catering to industries looking for long-term solutions without extensive overhauls. As industries rapidly evolve, the flexibility that Eaton Valves provide can lead to sustainable growth and expansion strategies for businesses.

Eaton Proportional Valves utilize an electrical signal to modulate fluid flow and pressure within a system. This modulation directly correlates with the input signal's magnitude, creating a proportionate output that ensures consistency and preciseness in system operations. The proportional control can adapt to real-time operational demands, providing optimal performance tailored to specific application needs. Their design allows for quick response times, making them suitable for applications requiring immediate adjustments.

The internal mechanisms of Eaton Proportional Valves are engineered to ensure smooth operation, which minimizes the risk of cavitation and other adverse effects that can impede performance. For instance, multiple orifices can be incorporated for various flow paths, enhancing the valve's ability to balance flow distribution effectively. This feature is particularly beneficial in complex systems where the coordination of multiple hydraulic actuators is necessary.

Choosing the right Eaton Proportional Valve involves understanding your specific system requirements. Key considerations include the pressure range, flow capacity, and system compatibility. It's critical to assess environmental conditions that the valve will face, such as temperature extremes, exposure to corrosive substances, and vibration levels. With this knowledge, professionals can select a valve that not only meets the immediate operational needs but also guarantees reliability and longevity.

Customers are also encouraged to consider future upgrades or expansions, ensuring that the selected valve will integrate seamlessly with potential new technologies. A forward-thinking approach might involve selecting valves that comply with future industry standards or that possess adaptable features for easy configuration with new systems. Engaging with Eaton's technical support and sales teams during the selection process can provide invaluable insights, matching specific needs with the most appropriate valve types available.

Proper installation and maintenance of Eaton Proportional Valves play critical roles in their overall performance and lifespan. When installing these valves, it is essential to follow Eaton’s guidelines closely. This usually includes ensuring proper alignment with hydraulic lines, confirming the appropriate voltage supply, and utilizing the right sealing methods to prevent leaks. It is also advisable to conduct a thorough system check post-installation, verifying that no air has entered the system, as air pockets can lead to performance inconsistencies.

Maintenance practices should include regular inspections of the hydraulic systems in which the valves are installed. This ensures that all components are free from wear and tear, that there are no signs of leakage, and that all connections remain intact. Creating a routine schedule for these inspections, alongside real-time monitoring capabilities, can enhance operational engagement and mitigates risks associated with unexpected failures. Eaton's support documents and tools further assist in this process, providing maintenance tips tailored to the specific valve models.

Eaton Proportional Valves are indispensable in achieving optimal fluid dynamics in industrial systems. Their advanced design and adaptability ensure that industries can maintain high levels of efficiency and reliability, making them a wise choice for businesses aiming to enhance operational effectiveness. As technology continues to evolve, Eaton remains committed to innovation, harnessing industry advancements to refine their products further. This commitment not only benefits current users but also positions Eaton Proportional Valves as a future-ready solution in a rapidly changing industrial landscape.

The landscape of hydraulic systems is continually evolving, driven by advancements in technology, the push for efficiency, and increased regulatory requirements. Eaton is poised at the forefront of developing Proportional Valve technology that addresses these trends. The future of valves, particularly Eaton’s proportional line, is expected to bring about smart connectivity through the Internet of Things (IoT), allowing manufacturers to harness data-driven approaches to maintenance and operation.

In a world where predictive analytics is becoming increasingly prevalent, Eaton’s incorporation of sensors and data analytics into their valve systems provides the ability to anticipate failures before they occur. This innovation can lead to a drastic reduction in downtime, as systems will be capable of self-diagnosing potential issues and prompting maintenance actions proactively. Such features could revolutionize industry standards by providing a fully integrated, intelligent hydraulic solution.

Moreover, as industries strive for sustainability, future Eaton Proportional Valves are likely to incorporate eco-friendly materials and manufacturing processes. This dedication to sustainability not only meets regulatory demands but also reflects a growing awareness and responsibility towards environmental stewardship that many organizations now embrace. The focus on energy efficiency will harmonize with the trend of designing hydraulic systems that minimize ecological footprints while maximizing performance.

Eaton Proportional Valves have already proven themselves as vital components within various industrial sectors, and the innovations on the horizon suggest an even brighter future. By emphasizing precise control, robust design, and commitment to sustainability, Eaton is setting itself up to meet the emerging demands of a continuously evolving industry landscape. Businesses that choose Eaton for their hydraulic needs are not only opting for a high-performance product but are also aligning with a legacy of innovation and excellence that will help drive efficiency and effectiveness for decades to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!