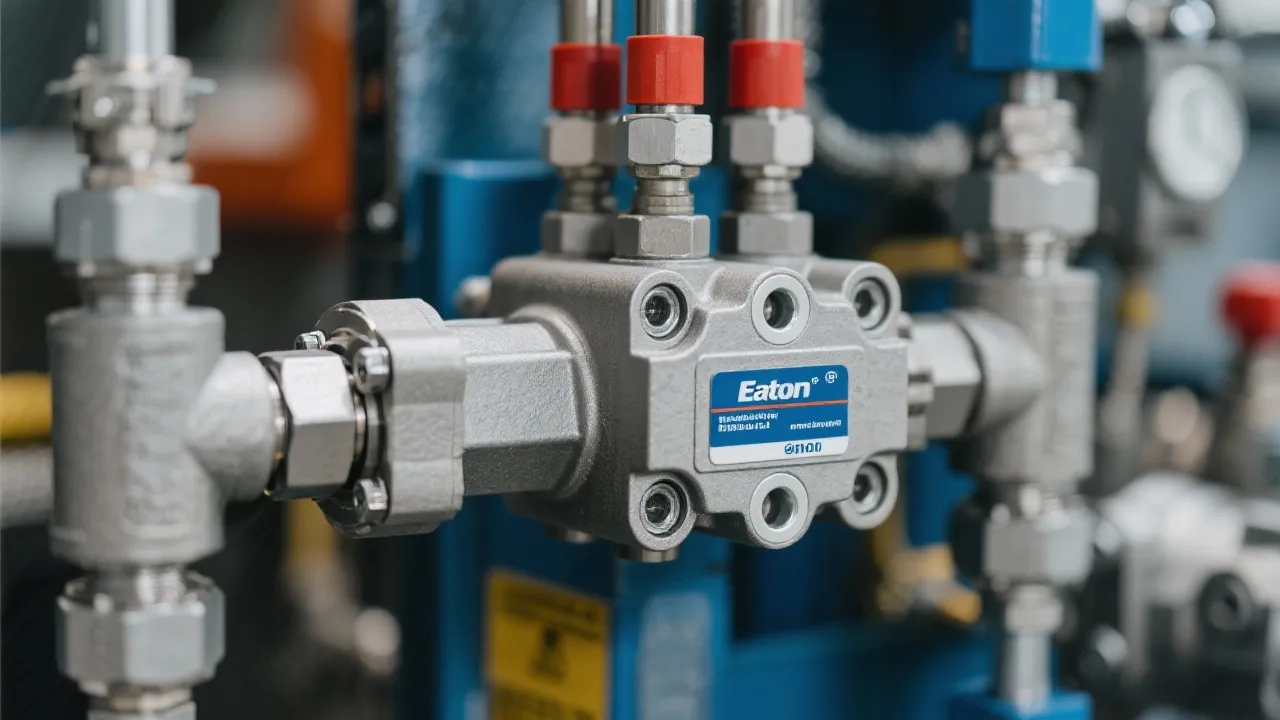

This guide explores the Eaton Proportional Valve, a key component in hydraulic systems used across various industries. Known for its precision and reliability, the Eaton Proportional Valve helps control fluid flow and pressure. The article provides an in-depth analysis from an industry expert's perspective, including functionality, applications, and FAQs, offering a comprehensive understanding for engineers and technicians.

The Eaton Proportional Valve plays a crucial role in modern hydraulic systems, mainly due to its ability to precisely control fluid flow and pressure. These valves are indispensable in industrial applications, including manufacturing, automotive, and aerospace industries, where precision and reliability are non-negotiable. By employing advanced technology, these valves help maintain optimal efficiency in complex systems. Beyond basic applications, the versatility of Eaton Proportional Valves allows them to adapt across various sectors, enhancing system functionality and performance.

At the heart of these valves is the ability to translate electrical signals into proportional hydraulic outputs, modulating the flow and pressure of hydraulic fluid with high precision. The core of its operation lies in an electromagnetically controlled spool or poppet. As voltage is applied, it adjusts the force exerted by the magnet, thus controlling the valve position, which in turn regulates fluid flow. This mechanism allows for real-time adjustments based on varying operational requirements, such as load fluctuations in machinery or changes in environmental conditions.

To enhance understanding, consider a scenario in an industrial robot application where precise movement is necessary for assembly tasks. The Eaton Proportional Valve receives input from the control system, which dictates the desired position of the robot arm. Based on this input, the valve adjusts the hydraulic fluid flow to the actuator controlling the arm, allowing for smooth, precise movements. The ability to rapidly adjust fluid flow enables the robot to perform delicate tasks without overshooting or underperforming, showcasing the valve's significance in automation.

Proportional valves by Eaton are renowned for their versatility and are utilized in various systems such as servo-hydraulic controls, machine tools, and injection molding. They offer several benefits, including:

In addition to these primary benefits, Eaton Proportional Valves are engineered to withstand diverse environmental challenges, such as extreme temperatures, humidity, and vibrations. This resilience expands their usability in sectors like construction, mining, and agriculture, where equipment is exposed to demanding conditions. Moreover, the integration of feedback mechanisms provides operators with real-time data on valve performance, allowing for proactive maintenance and operational adjustments for enhanced efficiency.

| Feature | Eaton Proportional Valve | Competitor Valve |

|---|---|---|

| Control Precision | High | Medium |

| Durability | Excellent | Good |

| Energy Efficiency | Superior | Average |

| Response Time | Immediate | Delayed |

| Integration Ease | Seamless | Moderate |

Installing an Eaton Proportional Valve ensures precision and efficiency in hydraulic systems. Below is a detailed step-by-step guide for proper installation:

A successful installation of an Eaton Proportional Valve not only ensures operational efficiency but also underscores the importance of meticulous attention to detail in hydraulic systems. By following these steps, technicians can ensure a smooth integration of the valve, ultimately maximizing the performance of the hydraulic system as a whole.

Maintaining the performance of an Eaton Proportional Valve requires regular inspections and systematic checking of multiple components. Technicians should check for wear and tear, which could impact control precision and efficiency. Regular cleaning of components is also recommended to prevent contamination that may affect valve functionality. Key maintenance practices include:

Moreover, it is vital to implement a systematic troubleshooting process when issues arise. Common issues include inconsistent flow rates, sluggish response times, or failure to actuate. Begin by diagnosing the electronic control signals; if they are valid, move on to the valve itself, checking for mechanical integrity. In cases of persistent issues, consulting Eaton’s technical support or referencing the valve's manual can provide additional guidelines specific to that model.

Q: What makes Eaton Proportional Valves stand out?

A: Their precision control and energy efficiency make them ideal for demanding applications that require reliability and performance. In addition, their robust construction and adaptability set them apart from competitors, enabling seamless operation across various industries.

Q: How often should maintenance be performed?

A: Maintenance frequency depends on the application, but generally, every 6-12 months is advisable to keep the systems running optimally. For mission-critical systems, monthly inspections can further safeguard performance.

Q: Are these valves compatible with existing hydraulic systems?

A: Yes, Eaton Proportional Valves are designed for adaptability, allowing seamless integration into a variety of hydraulic systems. Customization options are often available, making it easier to fit them into legacy systems requiring upgrades.

Q: What types of feedback systems are commonly used with Eaton Proportional Valves?

A: Feedback systems often include position sensors (like linear encoders), pressure transducers, and flow meters. These systems help ensure that the hydraulic output matches the desired parameters, leading to enhanced overall control.

The Eaton Proportional Valve represents a significant advancement in hydraulic technology, offering precision control, durability, and efficiency. It is an essential component for engineers and technicians seeking reliable solutions in industrial applications. With the right installation and maintenance practices, these valves can significantly enhance the operational efficiency of hydraulic systems, ultimately contributing to better productivity and lower operational costs. Their presence in critical systems cannot be overstated, as they enable complex machinery to operate seamlessly in a variety of challenging environments.

As industries evolve towards automation and greater integration of smart technologies, the future of proportional valve technology, including Eaton's offerings, is poised for significant advancements. Innovations around digital control systems, machine learning for predictive maintenance, and integration with IoT (Internet of Things) platforms can dramatically reshape how these valves operate and interact with larger hydraulic systems.

One anticipated trend is the improved integration of qualified sensors that could constantly monitor valve performance in real-time. These sensors would collect data that informs predictive algorithms, indicating when a valve might need maintenance before it malfunctions. Such proactive approaches could save industries considerable amounts in downtime and maintenance costs while improving overall system reliability.

Furthermore, the ongoing push for sustainable practices across industries prompts demand for energy-efficient solutions that Eaton Proportional Valves naturally fulfill. With an increasing focus on reducing the carbon footprint of industrial activities, the ability of these valves to minimize energy consumption while enhancing operational effectiveness positions them as critical components in green technology initiatives.

In summary, Eaton Proportional Valves epitomize the forefront of hydraulic technology, expertly merging innovation with practical applications to transform conventional systems into advanced, precise, and energy-efficient operations. Their importance is further magnified in a world where efficiency and adaptability are paramount, ensuring they remain integral to modern engineering solutions across diverse industries.

Whether dealing with complex robotic systems, automotive applications, or large-scale manufacturing, the capability of Eaton Proportional Valves to enhance performance through precision fluid control not only meets the current demands of the industry but firmly positions them to lead the charge into the future of hydraulic performance innovation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!