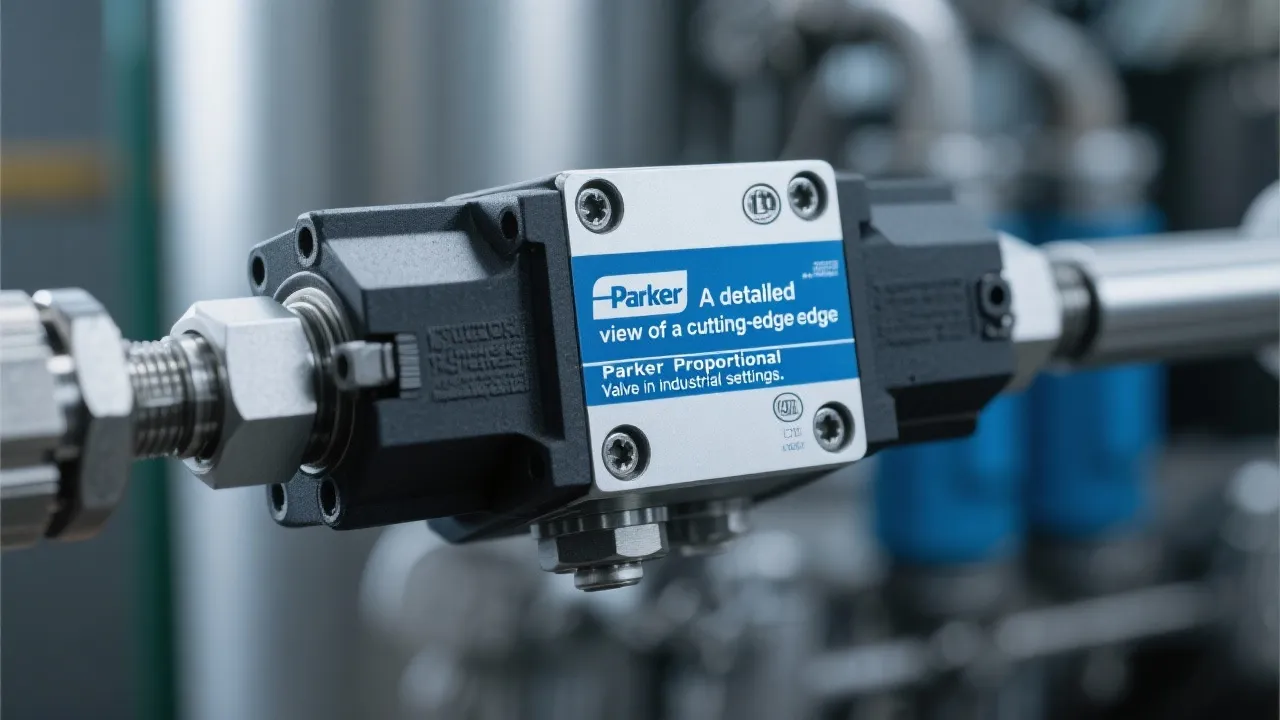

Parker Proportional Valves are integral components in industrial fluid control systems, offering precise regulation of flow and pressure. These valves are essential in automation and various engineering applications, ensuring enhanced performance and efficiency. Their versatility and precision make them a top choice for engineers and manufacturers globally, who rely on them for improved system control and reliability.

Parker Proportional Valves are a cornerstone in the field of industrial automation and fluid control systems. These valves stand out for their ability to precisely control the flow and pressure of fluids, making them indispensable in diverse applications ranging from automotive systems to intricate manufacturing processes. In an era where precision control is paramount, understanding the capabilities and applications of Parker Proportional Valves is crucial for engineers and system designers. Their sophisticated functionality not only enhances equipment performance but also contributes to the overall efficiency and sustainability of industrial operations.

Unlike traditional valves, which offer only binary on/off control, proportional valves issue a greater degree of control over fluid flow. This enhanced control allows for smoother operation of machinery and improved energy efficiency. By modulating the valve position precisely, systems can respond dynamically to changes in demand or load conditions, which is essential for modern automated systems. This ability to provide a variable flow rate enables applications to scale performance according to operational needs, resulting in reduced stress on components and increased longevity of equipment.

Moreover, the controlled modulation of fluid flow fosters not only efficiency but also accuracy in processes that require specific pressure settings. For instance, in hydraulic presses used in manufacturing, even minor fluctuations in pressure can lead to defects in materials produced, impacting product quality. Proportional valves thus prevent such discrepancies by maintaining the desired operational pressure throughout the system.

These valves are integral in industries where precision and reliability are critical. They are extensively used in hydraulic systems, HVAC systems, and any application requiring precise control of gas or liquid flow. Their ability to accurately regulate and understand system output makes them invaluable in settings demanding strict quality control and operational efficiency.

In the automotive industry, for example, Parker Proportional Valves are used in anti-lock braking systems (ABS) and electronic stability control systems, where they play a key role in managing fluid workflows to ensure optimal vehicle performance and safety.

In aerospace, these valves have vital applications in flight control systems, where exact timing and precision of control are necessary for safe and efficient operation. Proportional control valves are essential in maintaining the necessary hydraulic pressure in flight control surfaces, contributing to aircraft stability.

Industrial manufacturing processes also benefit from these advanced valves, particularly in robotics and automated machining systems. Proportional Valves allow for precise actuation and positioning, enabling intricate assembly or machining processes to be carried out with minimal error, thus improving product quality and reducing waste.

| Feature | Parker Proportional Valve | Traditional Control Valve |

|---|---|---|

| Control Precision | High | Low |

| Energy Efficiency | High | Medium |

| Reliability | Excellent | Variable |

| Cost | Higher initial cost | Lower initial cost |

| Application Range | Broad | Narrow |

| Response Time | Rapid | Slow |

| Maintenance Requirements | Lower | Higher |

Industry experts emphasize the importance of integrating Parker Proportional Valves into modern control systems. Their capability to enhance the precision and efficiency of any given system is invaluable. Moreover, as industries increasingly prioritize sustainability and cost-effectiveness, these valves offer significant advantages through reduced energy usage and minimization of maintenance and downtime. The investment in Parker Proportional Valves can lead to lowered operational costs in the long run, making them economically favorable despite their higher initial cost.

Experts also highlight the role of Parker Proportional Valves in supporting the transition towards automation and Industry 4.0 solutions. With the advancement of data analytics and the necessity for real-time monitoring, proportional valves equipped with digital communication technologies are essential for developing smart factories. The ability to integrate these valves into complex networks enables manufacturers to optimize production in real-time, further enhancing competitive advantages.

Q: What industries benefit the most from Parker Proportional Valves?

A: While many industries benefit, the automotive, aerospace, and manufacturing sectors particularly rely on these valves for precision control and efficiency. Other sectors such as pharmaceuticals, food and beverage, and energy production also utilize them to ensure strict adherence to regulatory standards and operational effectiveness.

Q: Are Parker Proportional Valves suitable for both gases and liquids?

A: Yes, these valves are designed to handle both gases and liquids, offering versatile applications in various fluid control systems. This adaptability makes them suitable for applications spanning from pneumatic systems in food processing to hydraulic systems in automotive assembly lines.

Q: How do Parker Proportional Valves improve energy efficiency?

A: By allowing precise control over flow and pressure, these valves optimize system performance, thereby reducing energy consumption and operational costs. The reduction in energy waste not only translates to cost savings but also aligns with global goals for sustainability, making industrial operations greener.

Q: What is the lifespan of a Parker Proportional Valve?

A: The lifespan can vary depending on application and maintenance; however, they are designed for durability, often lasting many years under proper conditions. Regular maintenance and monitoring can significantly extend their operational life. Additionally, advancements in manufacturing processes have enhanced the resilience of these valves against wear and tear.

Q: Can Parker Proportional Valves be integrated with automated control systems?

A: Absolutely, Parker Proportional Valves can be integrated with advanced automated control systems. They often support various communication protocols that facilitate synchronization with programmable logic controllers (PLCs) and other automated machinery, allowing for smoother operations across the entire manufacturing or processing facility.

To ensure the longevity and optimal performance of Parker Proportional Valves, proper maintenance is essential. Regular checks on valve operation, cleanliness, and hydraulic fluid quality can prevent common issues. Here are some essential maintenance tips:

Troubleshooting common issues with Parker Proportional Valves involves understanding their operational parameters and addressing discrepancies based on symptom diagnosis. If a valve is not responding correctly, it may be due to an electrical failure, hydraulic fluid issue, or mechanical malfunction. For example, if a valve is failing to modulate appropriately, check the signal input, wire connections, and ensure that there is no obstruction in the fluid path. For complex problems, consulting technical support or referring to the manufacturer’s guidelines can lead to effective solutions.

As automation continues to evolve, the technology behind Parker Proportional Valves is expected to advance significantly. The trends shaping the future of valve technology include:

Parker Proportional Valves play a critical role in enhancing industrial efficiency through precise fluid control. Their unparalleled precision, adaptability, and efficiency make them an integral component in modern automated systems. As industries continue to evolve, the demand and importance of these essential components are only expected to grow, making understanding and integrating them essential for future readiness and competitiveness. With advancements in technology paving the way for smarter and more efficient valve solutions, there is no doubt that Parker Proportional Valves will remain at the forefront of fluid control innovations in the years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!