Parker Proportional Valves are crucial in industries requiring precise fluid control. These valves offer unparalleled accuracy in applications ranging from manufacturing to aerospace. Highlighting their importance, we explore their functions, advantages, and industry applications, providing a comprehensive guide for professionals and engineers seeking detailed insights into their operation.

Parker Proportional Valves are a pivotal component in industrial automation, offering precise control over fluid flow in various systems. These valves excel in providing an accurate modulation of pressure and flow rates, making them indispensable tools for industries that demand precision and reliability. From manufacturing to aerospace, Parker Proportional Valves play a crucial role in optimizing system performance and efficiency. This article explores their technical specifications, real-world applications, and the benefits they offer.

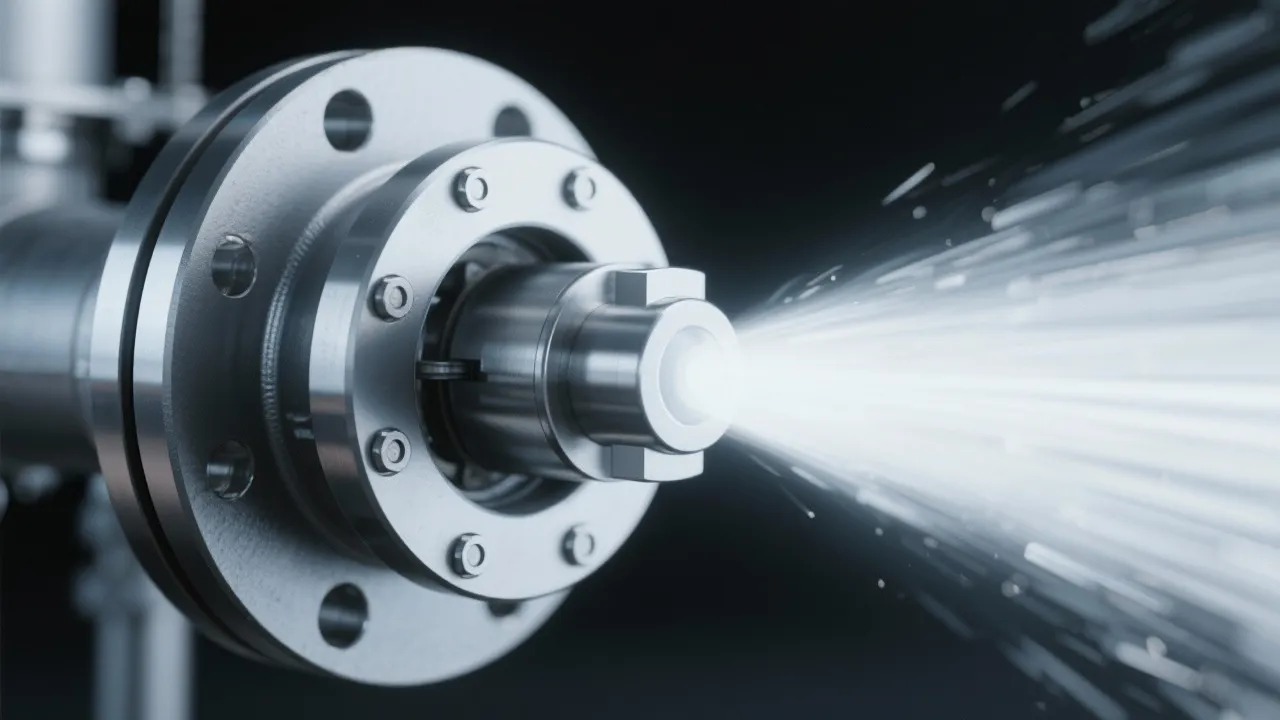

Parker Proportional Valves are designed to provide a variable output that corresponds to an input signal, allowing for graduated adjustments instead of just an on/off action. This variable control is achieved through sophisticated electronic and hydraulic integrations, which convert electrical signals into precise mechanical movements. Their ability to precisely manage flow and pressure in a system enhances the dynamic performance, stability, and safety of operations across various sectors. The engineering behind these valves involves a range of competences, including fluid dynamics, systems integration, and control logic, which collectively contribute to their performance.

One notable feature of Parker Proportional Valves is their response time. The valves can quickly adjust to changes in input signals, permitting rapid variations in flow and pressure. This rapid response is vital in situations where real-time adjustments are crucial—for instance, in robotic applications, where precision positioning is essential for effective operation. Furthermore, advancements in materials science have led to the development of components that reduce wear and increase durability, which is particularly important for industries where reliability is non-negotiable.

In the realm of automated systems, operational efficiency is paramount. Parker Proportional Valves ensure optimal functionality through their ability to finely tune the valve position according to the required flow rates and pressures. They utilize closed-loop control systems that integrate feedback mechanisms to ensure that the desired output is achieved consistently. The benefits of this capability extend beyond mere performance; they can lead to significant reductions in energy consumption, operational costs, and downtime related to system failures.

Due to their adaptable nature, these valves find applications in sectors such as automotive manufacturing, where they contribute to precise robotics control, and in the aerospace industry where they help manage critical hydraulic systems under demanding conditions. They are instrumental in hydraulic systems where the management of fluid dynamics is non-linear, allowing for smoother operation and longer life cycles for machinery. For example, in the operation of aircraft landing gear systems, Parker Proportional Valves provide seamless transitions between various phases, ensuring both safety and performance in critical situations.

| Feature | Description | Advantage |

|---|---|---|

| Precision Control | Adjusts flow rates and pressures dynamically | Improves system efficiency and reliability |

| Robust Design | Designed to withstand demanding industrial environments | Ensures long service life and lowered maintenance costs |

| Versatile Applications | Applicable in diverse industries from automotive to aerospace | Allows broad utility across sectors |

| Feedback Mechanism | Incorporates feedback loops for real-time adjustments | Enhances accuracy and control |

| Energy Efficiency | Optimized for minimal power consumption | Reduces operational costs |

Looking towards the future, the development of Parker Proportional Valves is geared towards further integration with smart technologies. The integration with IoT enables real-time monitoring and remote adjustments, which means that future iterations of these valves will not only execute tasks more efficiently but also contribute to predictive maintenance and system optimizations. This evolution is essential for industries looking to enhance productivity and adapt to the fast-paced technological landscape. By implementing machine learning algorithms, these valves could analyze patterns in fluid dynamics and adjust operations predicated on predictive analytics.

Additionally, advances in artificial intelligence (AI) could enhance the decision-making processes within the control systems of Parker Proportional Valves. AI implementations could help in diagnosing system anomalies and could provide insights into long-term performance trends, guiding operators in maintenance scheduling and operational adjustments. Furthermore, as industries move towards sustainable operations, Parker is likely to invest in developing valves that not only optimize fluid dynamics but also minimize environmental impacts, potentially leading to innovations in eco-friendly materials and energy sources.

To exemplify the real-world applications and benefits of Parker Proportional Valves, several case studies can be highlighted. In the automotive industry, a leading automotive manufacturer adopted Parker Proportional Valves in its robotic assembly lines. The introduction of these valves allowed for more intricate control of robotic arms, leading to enhanced precision in the placement of components. As a result, the company reported a significant reduction in component errors and waste, translating to lower production costs and increased quality assurance.

In aerospace, a major airline implemented Parker Proportional Valves in its fleet maintenance system. These valves helped refine the hydraulic systems used in their aircraft, allowing for smoother operations of essential functions such as wing flap adjustments and landing gear deployment. Post-implementation analysis indicated that maintenance costs dropped significantly, and the operational reliability of the aircraft improved, demonstrating the critical role that these valves can play in ensuring safety and efficiency in high-stakes environments.

The rise of Industry 4.0 is marked by an increasing reliance on intelligent automation and robotics. Parker Proportional Valves are integral to this evolution due to their adaptability and precision. In automated factories, where operations are increasingly being streamlined for higher efficiency, the requirement for exact control over fluid movements becomes evident. Parker’s integration solutions allow for scalable systems that can respond to fluctuating demand without compromising productivity levels.

For instance, in automated packaging lines, Parker Proportional Valves can adjust flow based on real-time feedback from sensors monitoring product throughput. In scenarios where demand spikes, these valves can modulate their output to maintain steady operations, ensuring that bottlenecks do not occur. This level of dexterity not only enhances productivity but also contributes to energy savings, aligning with the objectives of modern manufacturing to reduce overall carbon footprints.

The advantages of incorporating Parker Proportional Valves into industrial systems extend well beyond immediate performance enhancements. Some of the key benefits include:

Parker Proportional Valves stand as a testament to the importance of precision in the industrial sector. Their ability to seamlessly integrate into complex systems makes them a key component in modern engineering solutions. As industries continue to seek improved accuracy and efficiency, Parker's commitment to innovation ensures that their proportional valves will remain at the forefront of industrial automation and fluid control technologies. The continued evolution of these valves points towards a future where systems can operate autonomously, guided by intelligent control strategies that maximize output while minimizing environmental impact, thus contributing to a sustainable industrial ecosystem.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!