2frm Rexroth is a prominent term in the realm of hydraulic technology, known for its robust systems and applications in industrial automation. These systems, manufactured by Bosch Rexroth, are synonymous with precision and durability. In this guide, we delve into the complexities of 2frm Rexroth systems, their unique functionalities, and the increasing demand for such systems in various industries, driven by automation and efficiency needs.

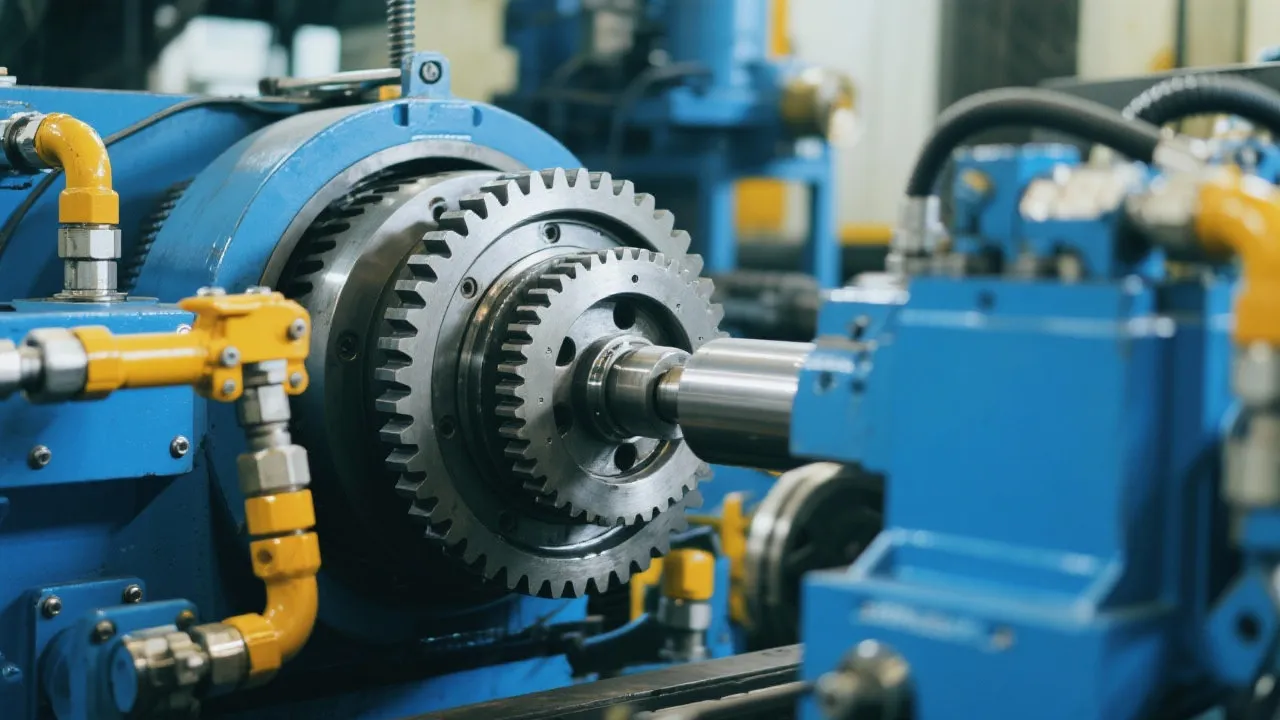

The 2frm Rexroth systems, produced by Bosch Rexroth, are integral components in the field of hydraulic technology. Known for their precision, reliability, and robust designs, these systems play a pivotal role in the automation of industrial operations. Employed in a range of applications, they have become synonymous with high-performance hydraulic solutions due to their adaptable nature. This adaptability allows their incorporation into various projects, from simple machinery to complex industrial systems. Their scalable nature empowers industries to respond to changing demands while maintaining high performance.

What sets the 2frm Rexroth systems apart is not just their impeccable design but also the advanced technology integrated within them. They utilize cutting-edge hydraulic engineering principles, ensuring that the systems can efficiently transfer power while minimizing fluid loss and maximizing mechanical performance. The innovations inherent in these systems are a result of Bosch Rexroth's long-standing commitment to research and development, which has led to numerous advancements in hydraulic technology over decades. A continuous focus on improving fluid dynamics, actuator integration, and electronic control has solidified the 2frm series as a reliable option in today's fluid power landscape.

Bosch Rexroth has established itself as a leader in motion control and automation technologies, evolving over time to meet the changing demands of the manufacturing sector. Its commitment to innovation and quality has made it a preferred choice for companies seeking reliable hydraulic systems. The 2frm Rexroth is a testament to Bosch's dedication to engineering excellence, offering advanced functionalities that cater to diverse industrial needs. Their extensive portfolio includes solutions for fluid power, linear motion, gear technology, and assembly technology, positioning them uniquely in the market.

The influence of Bosch Rexroth extends beyond just their products; they provide comprehensive support and consultation, assisting companies in optimizing their workflows and enhancing productivity. This holistic approach ensures that clients not only acquire high-quality products but also the expertise required to implement them effectively in real-world scenarios. As industries worldwide embrace automation to enhance productivity, Bosch Rexroth stands out for its forward-thinking strategies, embracing the digital transformation while solidifying its role as a key player in the industry.

Among the standout features of 2frm Rexroth systems are their robust engineering, energy efficiency, and versatility. These systems are designed to operate seamlessly in demanding environments, offering maximum uptime and optimal performance. The engineering behind the 2frm systems incorporates advanced materials that withstand potential wear and tear, ensuring longevity and reducing downtime costs. Moreover, the systems are continually evolving to integrate with digital solutions, enhancing their appeal in Industry 4.0 scenarios.

Another crucial aspect of the 2frm Rexroth systems is their energy efficiency. In an era where operational costs are directly linked to energy consumption, these systems boast features designed to minimize energy usage without compromising performance. For instance, they employ variable-speed drives and intelligent control mechanisms that adjust power output based on real-time operational demands. Such designs lead to significant cost savings over time as businesses realize reduced power bills and a smaller carbon footprint.

Furthermore, the adaptability of 2frm Rexroth systems allows them to be integrated into various processes and machinery. Whether used in robotic applications, assembly lines, or valve control, these systems demonstrate exceptional versatility. Their capability to interface with multiple control standards makes them ideal for environments where seamless communication between different technologies is paramount. The comprehensive functionality of these systems not only supports current needs but also anticipates future demands, which is vital as industries evolve.

2frm Rexroth systems find applications in numerous industries, ranging from manufacturing and construction to energy production and transportation. Their ability to maintain precision in fluid power control makes them indispensable in processes requiring high levels of accuracy. For example, in the manufacturing sector, they are often employed in automated assembly processes where consistent pressure and precise movements are crucial in ensuring the quality of products.

The construction industry, another significant sector, benefits from these hydraulic systems as they power equipment such as excavators, cranes, and other heavy machinery. The high-pressure capabilities and responsive control offered by 2frm Rexroth systems enable operators to perform complex tasks with precision. This enhances productivity and safety, as workers can rely on stable and calculated movements, thereby reducing the risk of accidents and improving efficacy.

Furthermore, in energy production, particularly renewable energies like wind and solar, the demand for precise hydraulic control systems is paramount. In wind turbine operations, for example, these hydraulic systems control the pitch of the blades, optimizing energy capture irrespective of changing environmental conditions. Similarly, in the solar industry, they are utilized to adjust solar panels' angle, ensuring maximum sunlight exposure. This adaptability to various applications directly correlates with improving overall energy efficiency by maximizing output while minimizing resource input.

While the benefits of 2frm Rexroth systems are clear, integrating them into existing operations requires careful planning. Factors such as compatibility with existing machinery, cost implications, and training for operational staff are critical considerations. Companies must thoroughly evaluate these aspects to ensure a seamless transition into the enhanced system. Failure to do so can lead to disruptions in production schedules and increased costs.

One prominent challenge is ensuring that existing machinery can accept the new 2frm Rexroth technology without requiring extensive modifications, which could involve significant additional labor costs and downtime. Conducting compatibility assessments before deployment is essential for identifying areas where integration may prove problematic. Businesses might consider running pilot projects to evaluate the feasibility of implementing the systems before committing to wider deployment.

Another important consideration involves cost management. While investing in advanced systems like the 2frm Rexroth may lead to long-term savings, the initial financial outlay can be substantial. Companies must budget not only for the systems themselves but also for the ancillary costs associated with training employees, retrofitting existing machinery, and potential downtime during the transition period. To mitigate these costs, companies can explore financing options or phased integration approaches, wrapping in new technologies gradually to manage budgetary impacts effectively.

The training of staff to handle these advanced hydraulic systems is equally crucial. As technology continues to evolve, so too does the need for specialized knowledge regarding operation, maintenance, and troubleshooting. Companies should invest in comprehensive training programs, utilizing Bosch Rexroth’s resources for technical education and best practices in hydraulic systems operation. This training will empower their workforce, ensuring safe operation and adherence to quality standards while improving efficiency across operations.

| Feature | Advantage |

|---|---|

| Robust Design | Ensures durability in harsh environments. |

| Energy Efficiency | Reduces operational costs through minimal energy consumption. |

| Adaptability | Versatile application across various industrial sectors. |

Industries such as manufacturing, construction, and energy production benefit significantly due to the systems' precision and reliability. Additionally, sectors such as automotive manufacturing, aerospace, and even agriculture leverage these systems to enhance operational efficiencies.

These systems are increasingly integrated with digital technologies, facilitating smarter, more automated industrial operations. By connecting with IoT devices and employing data analytics, the 2frm Rexroth systems enable real-time monitoring and control. This integration fosters predictive maintenance, reduces unplanned downtime, and supports quicker decision-making processes based on data-driven insights.

Key challenges include system integration with existing technologies, cost management, and ensuring adequate training for handling advanced machinery. Additionally, companies may face change management issues as they adapt their operations and supply chains to accommodate these modern systems, leading to the potential need for cultural shifts within organizations.

To prepare for the transition, companies should establish clear goals regarding what they wish to achieve with the new system, conduct compatibility assessments, and finalize a comprehensive training program for employees. Partnering with Bosch Rexroth for guidance during the deployment process can also ensure that companies navigate the integration smoothly and maximize the potential benefits of these advanced systems.

2frm Rexroth systems exemplify the pinnacle of hydraulic technology, with their advanced capabilities supporting increased industrial automation. Companies embracing these systems can expect enhanced operational efficiency and a competitive edge in the evolving market landscape. As industries continue to advance, stability, efficiency, and adaptability become paramount; thus, investing in high-performance systems like those provided by Bosch Rexroth positions organizations favorably against their competitors and prepares them for future challenges and opportunities in global markets.

Ultimately, with the proper implementation and adaptation strategies, the potential of the 2frm Rexroth systems can be fully realized, driving not just short-term gains but long-lasting improvements in operational performance and positioning companies for sustained success in their respective fields. The journey towards automation and efficiency is ongoing, and the 2frm Rexroth systems are equipped to lead companies through this transformative phase, making them indispensable assets in the modern industrial toolkit.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!