This comprehensive guide dives into the significance and applications of 4wrd Rexroth technology. Recognized for its innovation in hydraulic and automation solutions, 4wrd Rexroth plays a crucial role in various industrial sectors. This article explores its impact, benefits, and the factors driving its adoption in modern industry.

In the landscape of industrial technology, 4wrd Rexroth stands out as a beacon of innovation and reliability. Known for its advanced solutions in hydraulics and automation, this technology has revolutionized various sectors, including manufacturing, construction, and energy. The versatility of 4wrd Rexroth's products, from hydraulic components to fully integrated systems, signifies its profound impact on operational efficiency and precision. The company has evolved over the years, adapting to the changing demands of the market and continuously improving its offerings to meet and exceed customer expectations.

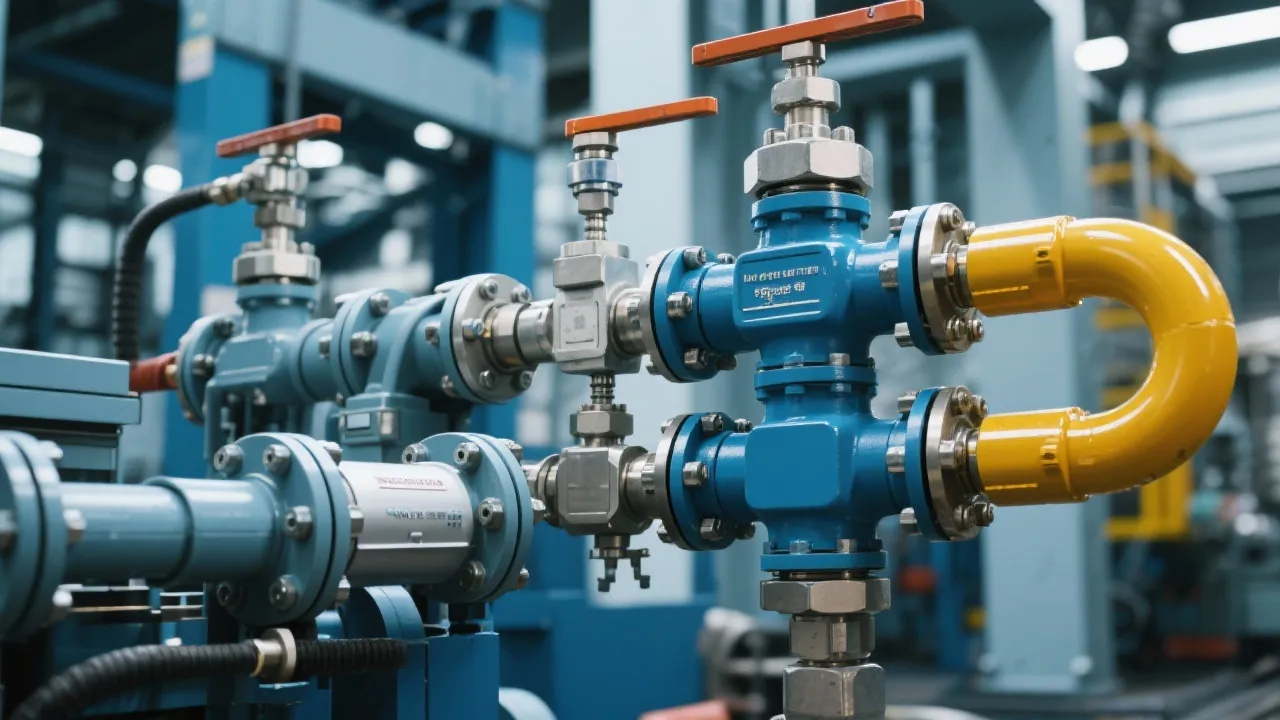

4wrd Rexroth is pivotal in enhancing the efficiency of industrial operations. This brand's commitment to quality ensures that equipment runs smoothly, reducing downtime and maintenance costs. Its products range from power units and pumps to sophisticated control systems that simplify complex processes. This adaptability makes 4wrd Rexroth a preferred choice among businesses aiming for sustainable growth and competitive advantage. This significance is underscored by the growing need for high-performance equipment that can deliver reliable results under varying conditions. As industries evolve and expand, the demand for advanced hydraulic solutions that can withstand rigorous operations continues to grow—thereby elevating Rexroth's role in the industrial machinery sector.

Industries such as automotive, aerospace, and marine heavily rely on 4wrd Rexroth for their operational needs. In the automotive sector, precise control of hydraulic systems is critical, and Rexroth's solutions provide unparalleled accuracy and reliability. For instance, hydraulic actuators and valves from Rexroth are employed in assembly lines to automate processes that demand high precision, such as welding and painting — ensuring consistent quality across production runs. Similarly, in manufacturing, the integration of automation with hydraulics maximizes productivity while minimizing energy consumption, resulting in cost savings and improved output rates. Furthermore, sectors like food processing, packaging, and pharmaceuticals also utilize Rexroth’s innovations to ensure sanitary and efficient operations.

In aerospace, 4wrd Rexroth products are integral to the operation of various systems, including flight control and landing gear mechanisms. The reliability and performance of hydraulic systems in this sector are paramount, and Rexroth’s technology meets strict regulatory requirements, ensuring safety and performance in flight operations. Additionally, in the marine industry, Rexroth products provide solutions for powerful hydraulic systems that operate steering, stabilization, and propulsion, contributing to improved maneuverability and operational efficiency at sea.

The appeal of 4wrd Rexroth stems from its robust technology and adaptive features. Key drivers for its adoption include the increasing demand for automation in industrial processes and the need for eco-friendly, energy-efficient solutions. Automation allows companies to streamline their operations, reduce labor costs, and enhance production capacity, all while maintaining the highest standards of safety and compliance. In this age of rapid technological advancement, industries are aware of the importance of harnessing the power of automation and integrating it into their workflows. Furthermore, globalization and the rise of Industry 4.0 have accelerated the implementation of advanced systems, reinforcing Rexroth's position in the market.

The environmental consciousness of modern consumers also plays a significant role in driving the adoption of Rexroth solutions. As businesses prioritize sustainability, the emphasis on integrating efficient technological systems to minimize waste and lower energy consumption becomes more pronounced. This aligns perfectly with Rexroth's commitment to developing innovative products that not only improve performance but also contribute positively to environmental goals. Companies increasingly seek partners who can help them transition to greener processes, and Rexroth has positioned itself strategically to fulfill this growing need.

| Component | Functionality |

|---|---|

| Hydraulic Pumps | Convert mechanical energy into hydraulic energy, crucial for various machine operations. Rexroth offers a wide range of hydraulic pumps designed for specific applications, ensuring optimal performance and reliability. |

| Power Units | Provide the energy required for different hydraulic systems, ensuring consistent performance. These power units can include a combination of hydraulic reservoirs, filters, and cooling systems, customized to meet the precise needs of each application. |

| Control Systems | Allow for precise regulation of machine actions, pivotal in automation processes. Rexroth’s control systems integrate advanced sensors and software that enable real-time data processing and feedback, enhancing the overall operation of machinery. |

| Actuators | Convert hydraulic energy back into mechanical motion, essential for moving equipment and executing tasks. Rexroth’s actuators boast high efficiency and responsiveness, ensuring that even the most demanding applications can be managed with precision. |

| Valves | Regulate the flow and pressure of hydraulic fluid within a system, crucial for controlling operations and ensuring safety. Rexroth provides a variety of valves, including directional control valves, pressure relief valves, and flow control valves, optimized for diverse applications. |

Innovation lies at the heart of 4wrd Rexroth's strategy, constantly pushing the envelope with new developments. As industries transition towards more automated frameworks, the demand for sophisticated control and hydraulic systems will surge. Rexroth is actively exploring new technologies, such as artificial intelligence and machine learning, to enhance its predictive maintenance capabilities. By analyzing data collected from machinery, Rexroth’s systems can anticipate potential failures and recommend maintenance actions before issues arise, thereby saving costs and preventing costly downtimes.

Moreover, the role of digital twins in industrial operations is gaining momentum, allowing for virtual modeling of physical machinery. Rexroth is at the forefront of integrating digital twin technologies, enabling businesses to simulate operations, optimize designs, and enhance overall system performance. This innovation allows manufacturers not just to visualize current operational conditions, but also to perform what-if analyses that could lead to significant optimizations in processes, design, and efficiency. As IoT technologies mature, Rexroth is well-positioned to lead the charge towards smarter factories where interconnected systems seamlessly communicate and operate with minimal human intervention.

Another exciting frontier for Rexroth is the development of more eco-friendly hydraulic fluids and components designed specifically for applications that require a lower environmental impact. This initiative aligns with global trends towards sustainability, allowing businesses to undertake operations that minimize ecological footprints while still delivering high performance. As Rexroth continues to innovate and redefine hydraulic systems, its ongoing commitment to sustainability and efficiency will become even more integral to its identity and product offerings.

4wrd Rexroth has cemented its reputation as a leader in industrial technology by providing robust, efficient, and cutting-edge solutions. As industries continue to evolve, Rexroth's role in fostering innovation and enhancing operational capabilities will remain indispensable. With a focus on sustainable practices and technological advancements, 4wrd Rexroth is well-positioned to drive future industrial milestones. By continuing to embrace new technologies and address the needs of its clients, Rexroth exemplifies the dynamic nature of industrial technology and its potential to transform processes across sectors.

The integration of more sensors and data analysis tools within Rexroth systems will facilitate smoother transitions to automated environments and provide organizations with insights to further improve operational efficiency. As the industry progresses towards greater complexity, the solutions offered by 4wrd Rexroth will become more critical than ever in navigating challenges, optimizing processes, and achieving growth. Overall, the future looks bright for 4wrd Rexroth as it embraces challenges and seizes opportunities in the ever-changing landscape of industrial technology.

In addition, customer collaboration is emerging as a crucial aspect of 4wrd Rexroth’s innovation strategy. By engaging with users directly and understanding their pain points and needs, Rexroth can tailor solutions that not only fulfill existing requirements but also anticipate future demands. This proactive approach to product development ensures that Rexroth remains at the forefront of technology development and can continue to offer solutions that empower industries worldwide.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!