Rexroth filters are a staple in the hydraulic and automation industries, designed to improve efficiency and performance by effectively removing contaminants from systems. As part of Bosch Rexroth’s extensive product line, these filters are engineered for reliability and long-lasting service. This article explores the significance of Rexroth filters, their applications, and the reasons they are favored across various industries.

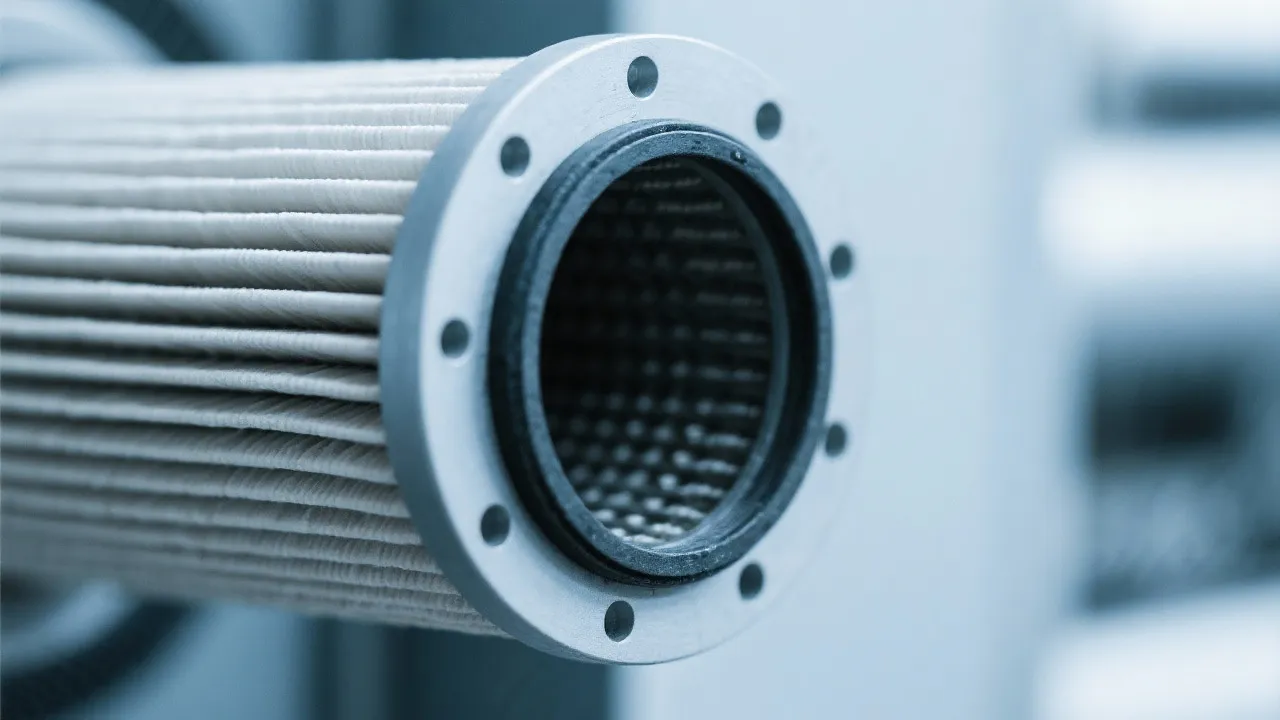

In the realm of hydraulic systems and industrial automation, Rexroth filters stand out due to their superior ability to enhance system performance by removing impurities. Designed and manufactured by Bosch Rexroth, a leader in drive and control technologies, these filters are crucial in maintaining system efficiency and longevity. Various design innovations such as advanced filtration media and unique construction principles distinguish Rexroth filters from other options on the market. Notably, these filters feature a combination of mechanical, chemical, and electrostatic filtration principles, allowing them to effectively trap particles of varying sizes while processing hydraulic fluids at high speeds.

Rexroth filters find application across a broad spectrum of industries, such as manufacturing, automotive, maritime, and aerospace. In manufacturing environments, they are utilized in hydraulic systems that power machinery like injection molding machines and CNC machining centers, ensuring that hydraulic fluids remain clean to prevent wear and tear. In the automotive industry, they play a critical role in hydraulic steering systems, brake fluid systems, and other critical fluid management operations. The maritime sector also heavily employs Rexroth filters to purify hydraulic fluids in ships and submarines, where a clean hydraulic system is essential for safety and operational efficiency. In aerospace, they are integrated into hydraulic systems of aircraft, where contamination could lead to catastrophic failures. Their main role is to purify hydraulic fluids, thereby preventing contamination that can lead to system inefficiencies and failures. By maintaining clean working environments, these filters reduce downtime and enhance the lifespan of machinery. With the increasing complexity of modern machinery, the role of these filters becomes even more vital as they operate optimally under high pressure and temperature conditions.

Efficiency and Performance: Rexroth filters are meticulously designed to offer high efficiency in contaminant retention, ensuring optimum performance of the system. Advanced filtration technologies, including depth filtration, surface filtration, and combination methods, are employed to maximize the filtration process. This not only helps in removing solid particles but also addresses liquid contaminants, improving the overall functionality of hydraulic systems significantly.

Durability: Built with high-quality materials, these filters provide resilience and long-lasting service, even in demanding industrial conditions. The construction involves robust materials that resist wear, corrosion, and high temperatures, making them ideal for use in harsh environments such as heavy machinery, mining equipment, and marine applications. Long-lasting filters reduce the frequency of replacements, contributing to lower operational costs and minimized downtime.

Versatility: Catered to a range of systems, these filters come in various sizes and filtration grades to meet different industrial needs. Whether used in large industrial hydraulic systems or compact applications, Rexroth offers a selection of filters that caters to specific requirements. This versatility extends to compatibility with various fluids and ambient conditions, making them suitable for global use across multiple sectors. Additionally, Rexroth filters can be customized to fit niche applications, further enhancing their effectiveness in specialized industries.

Opting for Rexroth filters is synonymous with choosing reliability and efficiency. Their technology ensures the removal of impurities at different filtration stages, significantly minimizing the risk of system failures. The ability of these filters to maintain fluid cleanliness translates to lower operational risks and improved safety, something paramount in industries such as aerospace and automotive. This choice leads to fewer maintenance interventions, ultimately saving costs and resources throughout the system’s lifecycle. Moreover, investing in Rexroth filters contributes to sustainability goals, as their efficient operation lessens energy consumption and minimizes the environmental impact associated with hydraulic fluid use. With dedicated service and support from Bosch Rexroth, users are assured consistent operational excellence and compliance with industry standards, thereby enhancing their systems' reliability and performance.

| Brand | Filtration Efficiency | Durability | Price | Additional Features |

|---|---|---|---|---|

| Rexroth | High | Very High | Premium | Advanced filtration media, customizable options |

| Brand A | Medium | High | Moderate | Basic filtration technologies |

| Brand B | Low | Medium | Low | No advanced features |

| Brand C | High | Medium | Moderate | Environmental focus, eco-friendly materials |

Experts often note that the implementation of Rexroth filters frequently results in a notable increase in system reliability and performance. Industry analysts suggest that as machinery and production processes become more sophisticated, the importance of efficient filtration systems will increase. The filters' advanced design allows for a lesser environmental impact thanks to more efficient operation, reducing power consumption across the board. Furthermore, companies utilizing high-quality Rexroth filters have reported significant reductions in hydraulic fluid waste, which not only leads to cost savings but also contributes to better environmental stewardship. The trend towards automation and digitalization in industries also emphasizes the need for dependable and efficient hydraulic systems, making Rexroth filters a strategic investment for businesses looking to upgrade or maintain their operations sustainably.

In conclusion, Rexroth filters are integral in achieving operational excellence and economy in various industries. Their adoption facilitates enhanced productivity, reduced maintenance costs, and increased system longevity, thereby providing a higher return on investment. As industries strive for better efficiency and reduced environmental impact, the role of high-performance filtration systems such as Rexroth filters will only continue to grow in importance. The trend toward automated systems requires reliable and effective filtration solutions that can adapt to evolving technologies and demands, ensuring that Rexroth filters remain at the forefront of technological advancements in fluid power systems. With an extensive service network and continued innovations, Bosch Rexroth stands ready to support its customers in optimizing their fluid management strategies, making Rexroth filters a preferred choice in competitive markets.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!